Widening device of high-power laser beam and method thereof

A laser beam, high-power technology, used in laser welding equipment, optics, optical components, etc., to achieve the effect of overcoming beam broadening width, high processing efficiency, and high laser energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

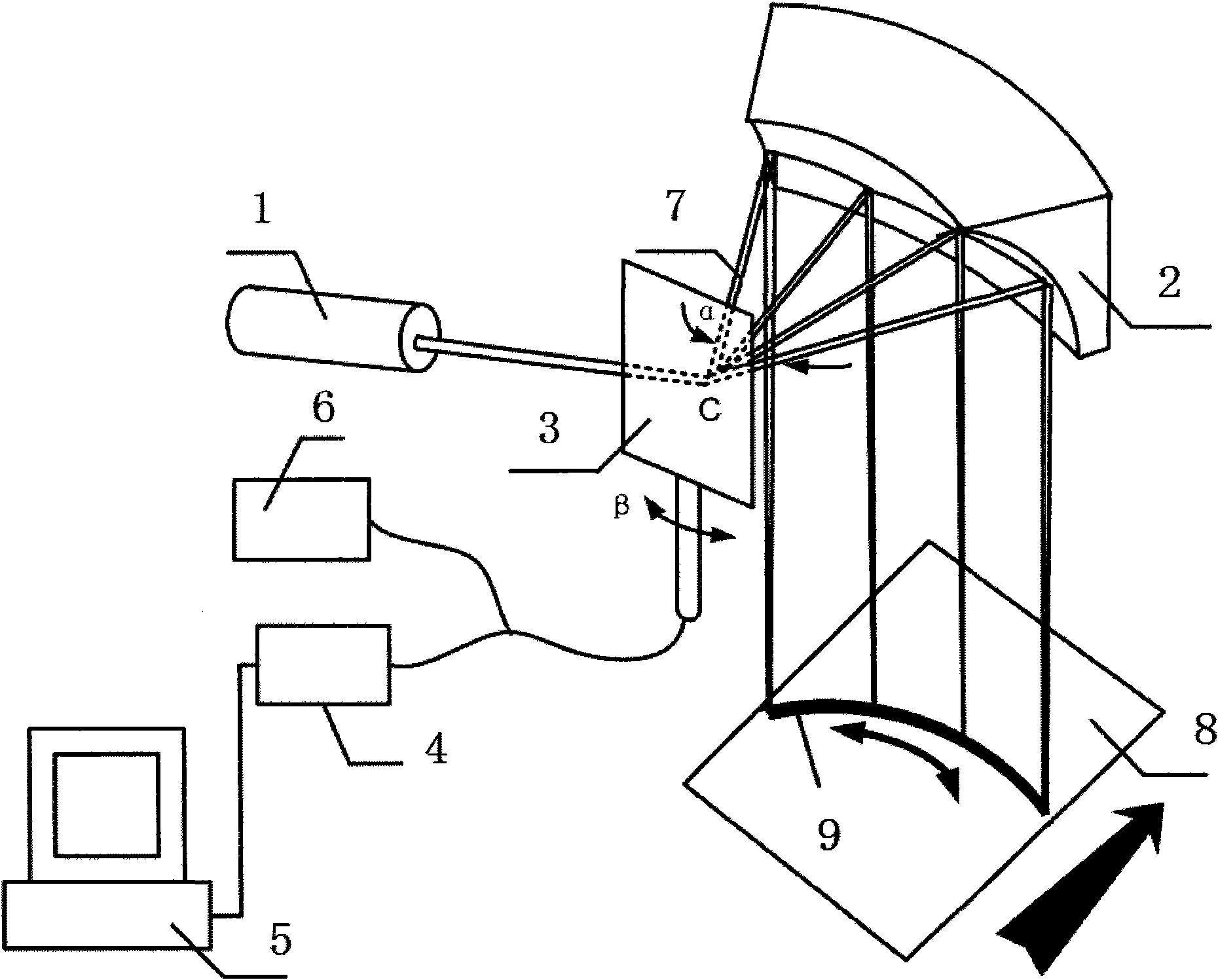

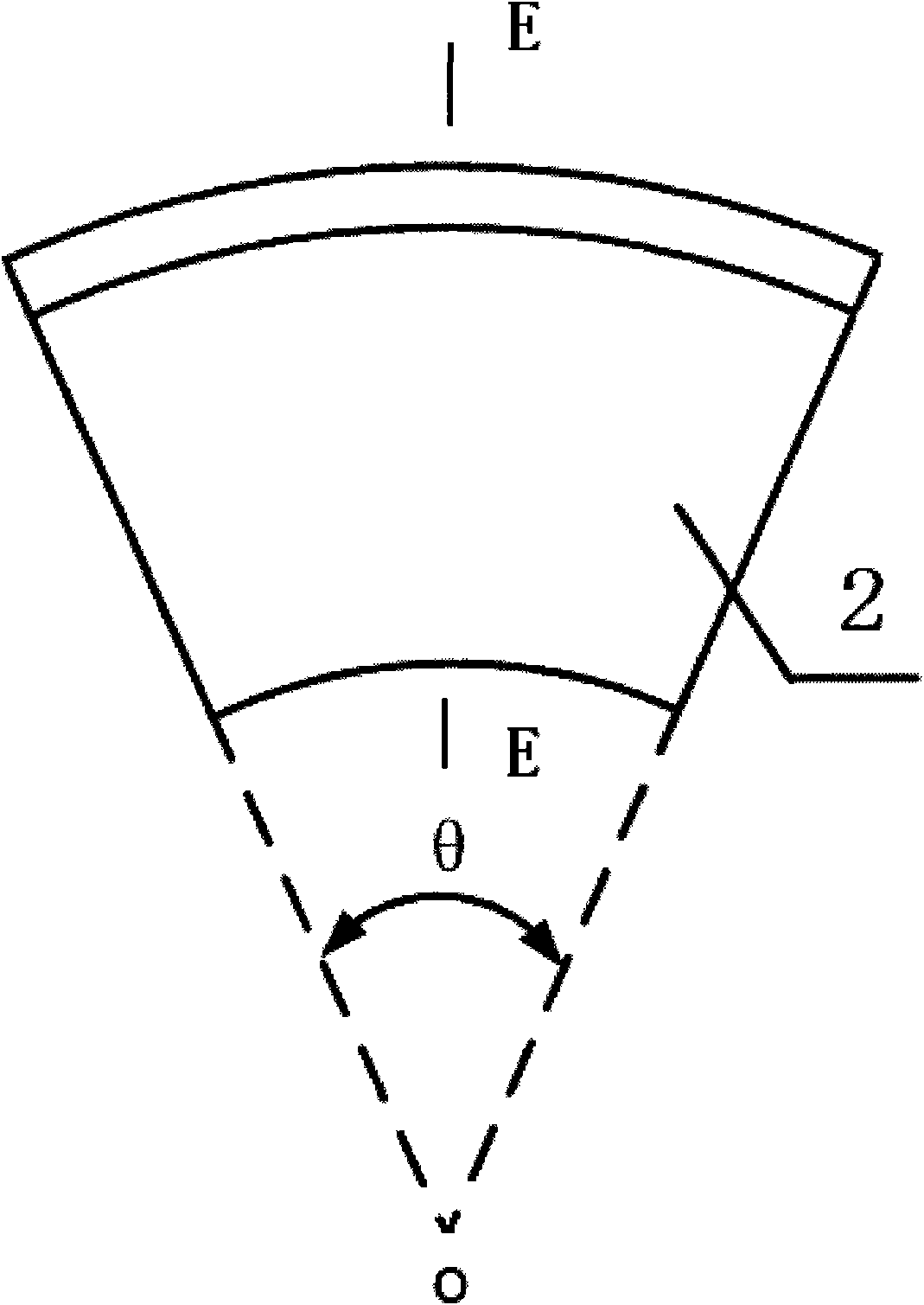

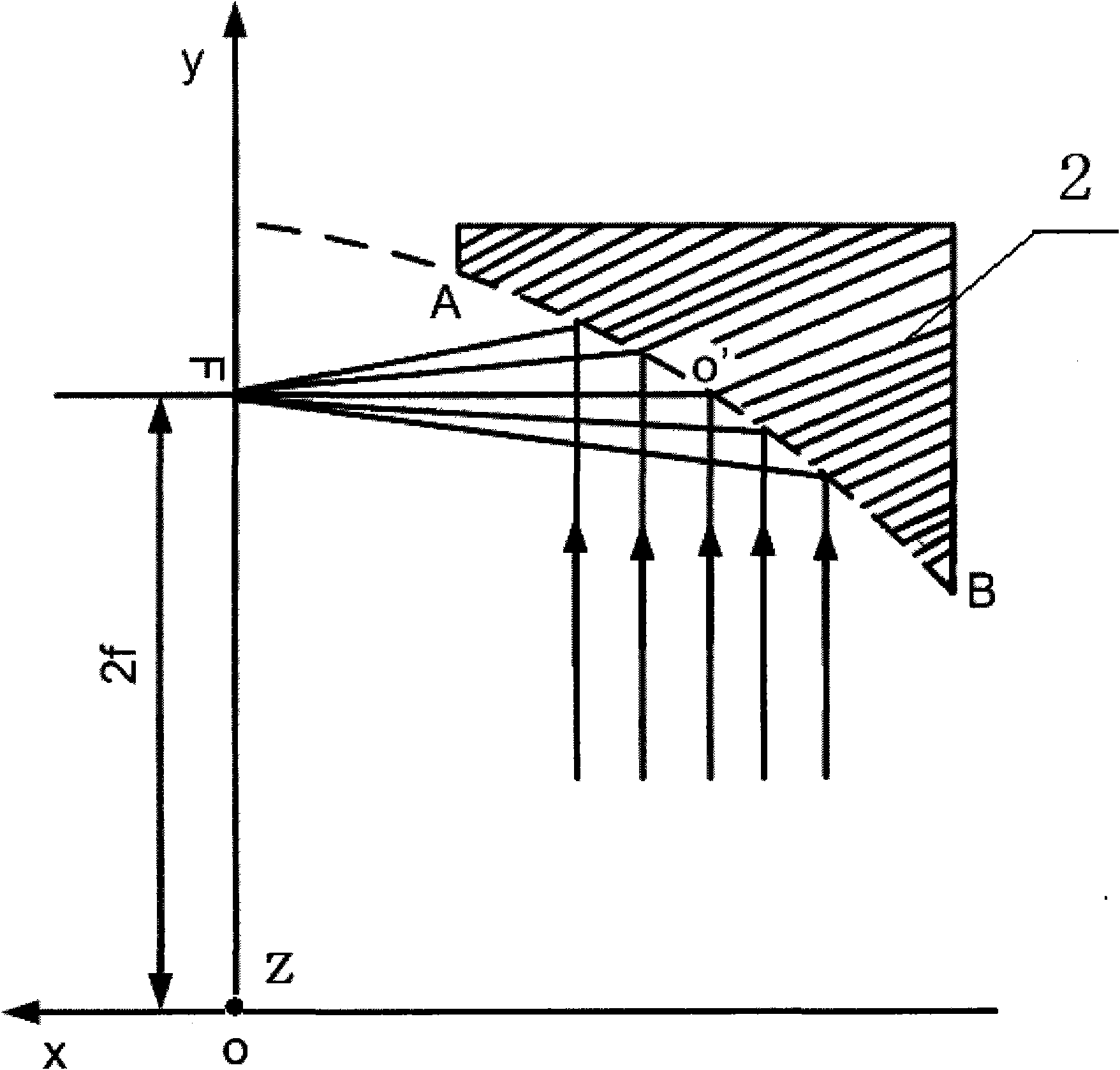

[0028] Embodiment: first as figure 1 As shown, the high-power laser beam stretching device provided in this embodiment is mainly composed of a continuous laser 1 , a fan-shaped reflective focusing mirror 2 , a deflecting galvanometer 3 , a high-speed motor 4 , a computer 5 and a refrigeration cycle system 6 . One side of the deflection galvanometer 3 is connected to the rotating shaft of the high-speed motor 4 , and the high-speed motor 4 is connected to the computer 5 , and the deflection angle β of the deflection galvanometer 3 can be controlled by preset parameters in the computer 5 . A cooling channel is opened in the deflection galvanometer 3 , and the cooling channel is connected with the refrigeration cycle system 6 . The deflecting galvanometer 3 is placed opposite to the fan-shaped reflective focusing mirror 2 , and the reflection point C of the laser beam emitted by the continuous laser 1 on the deflecting galvanometer 3 is concentric with the rotation center O of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com