Rotary type thermal treatment working platform

A working platform and rotary technology, used in heat treatment equipment, manufacturing tools, quenching devices, etc., can solve the problems of uneven quenching of castings, uneven heat treatment of large-quality workpieces, time-consuming and labor-intensive, and achieve uniform quenching and protection of normal operation. , the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

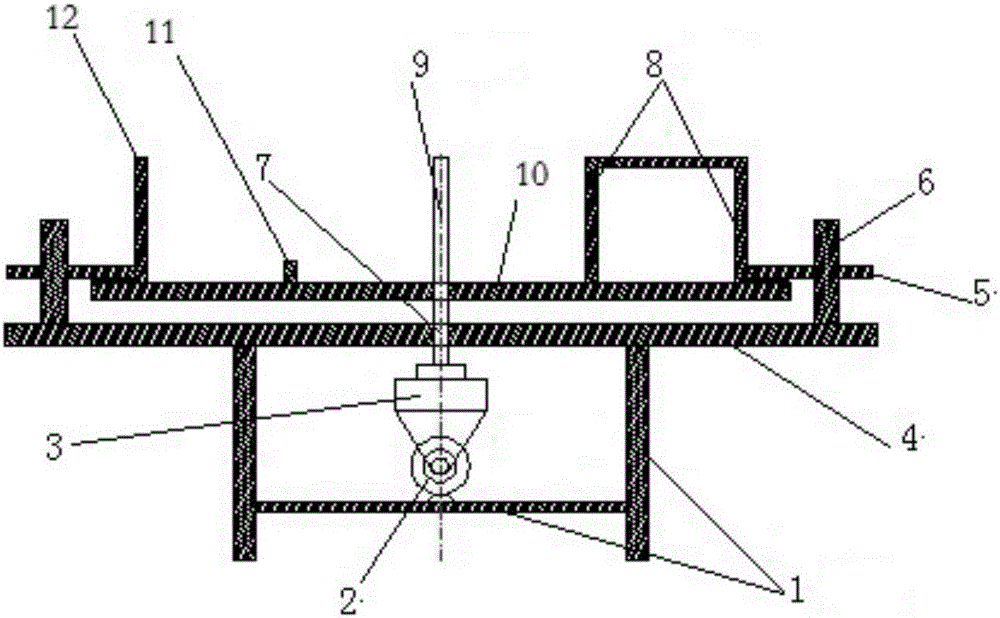

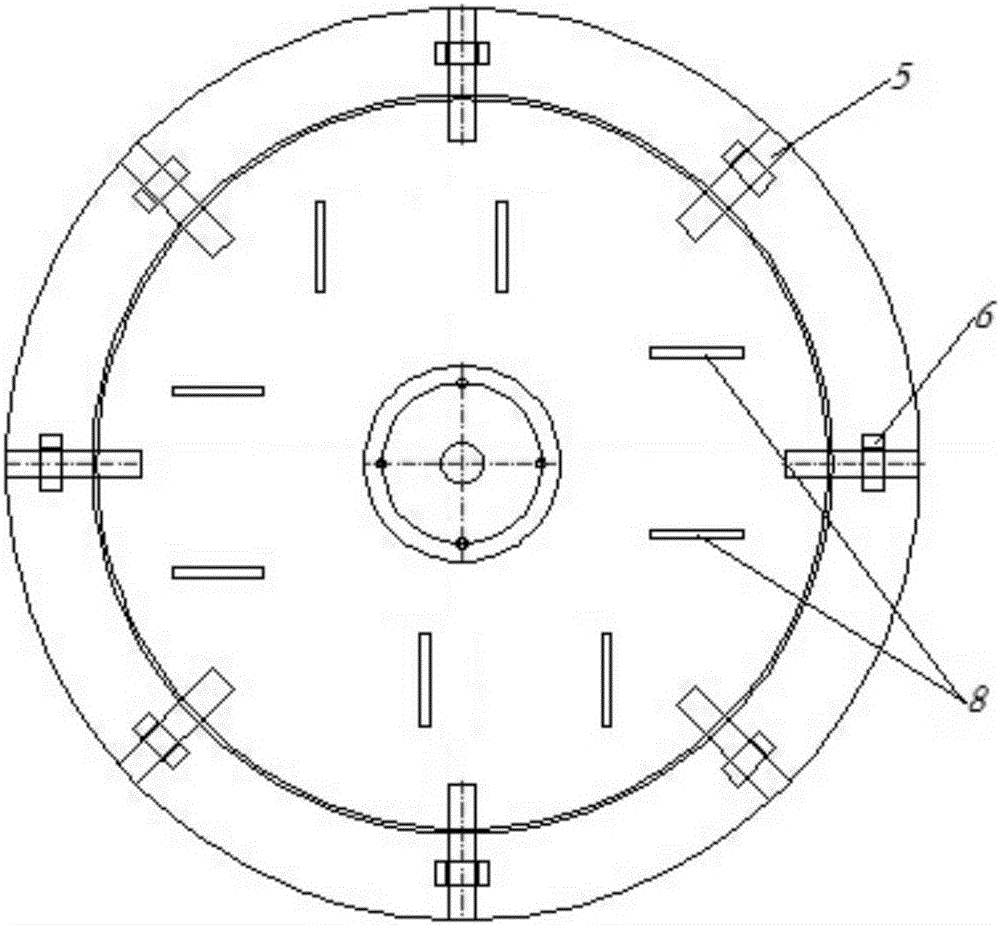

[0032] Such as figure 1 and figure 2 As shown, a rotary heat treatment work platform includes a support 1, a work platform 4, and a turntable mechanism, and is characterized in that: the work platform 4 is arranged on the support 1 and is fixedly connected with the support 1; the turntable mechanism includes a rotary drive device , turntable 10, and the roller device that is arranged on the periphery of turntable, described rotary driving device comprises motor 2, transmission device, drive shaft 9, and motor 2 is arranged on the support 1 and is positioned at work platform 4 below; Drive shaft 9 passes through work platform The positioning hole 7 on the 4 is connected with the turntable 10 to drive the turntable 10 to rotate, and 4 groups of supporting workpiece devices are arranged on the working surface of the turntable 10 .

[0033] The above-mentioned rotary heat treatment work platform is characterized in that the workpiece supporting device 8 includes a low support fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com