Heat-treating method for substrate and heat treating furnace

A heat treatment method and technology of heat treatment furnace, which are applied to furnaces, furnace components, furnace types, etc., can solve the problems of temperature distribution of substrates, inability to obtain uniform heat treatment quality, and difficulty in thermal influence, and achieve the effect of efficient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

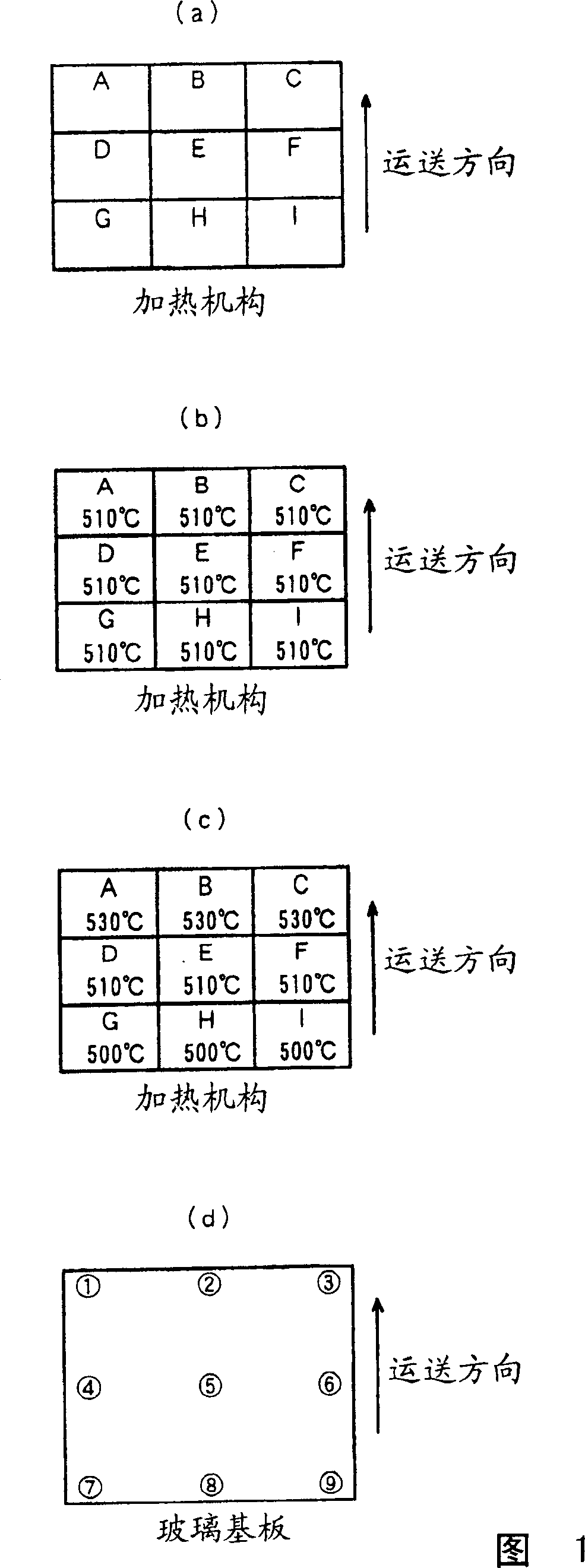

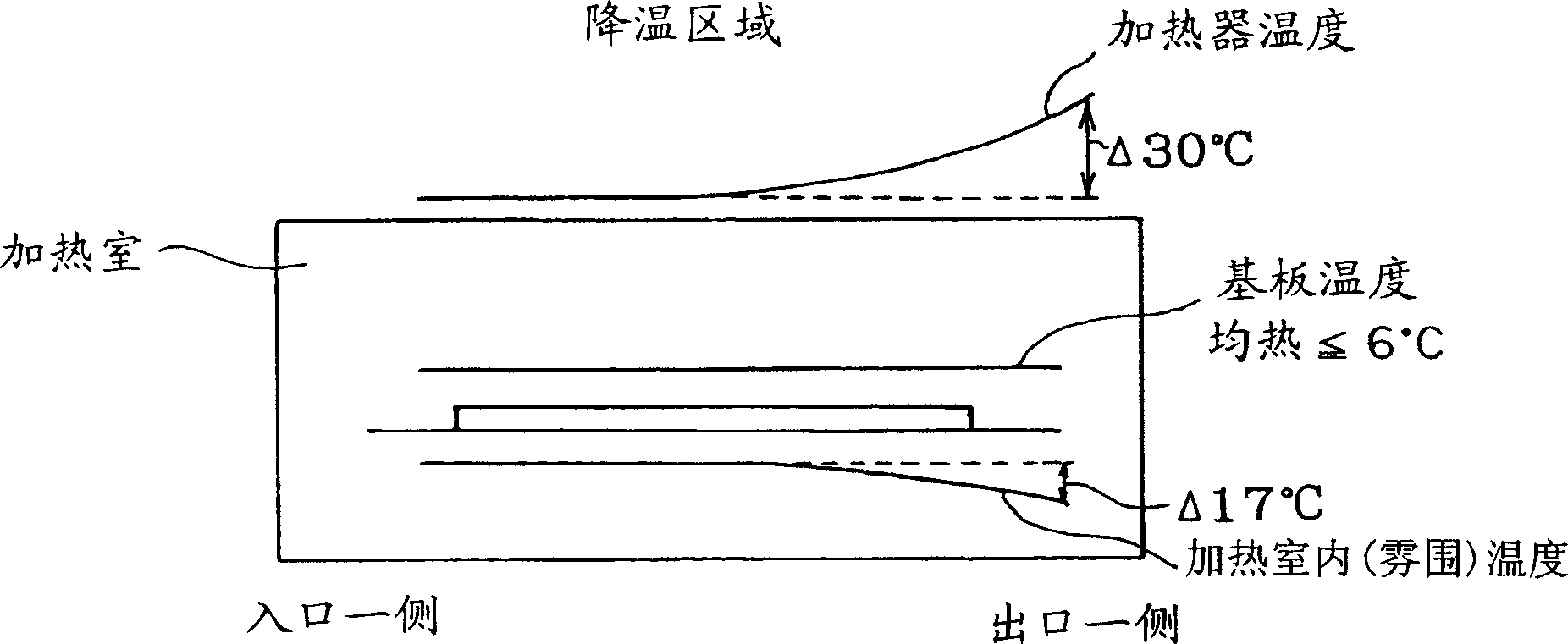

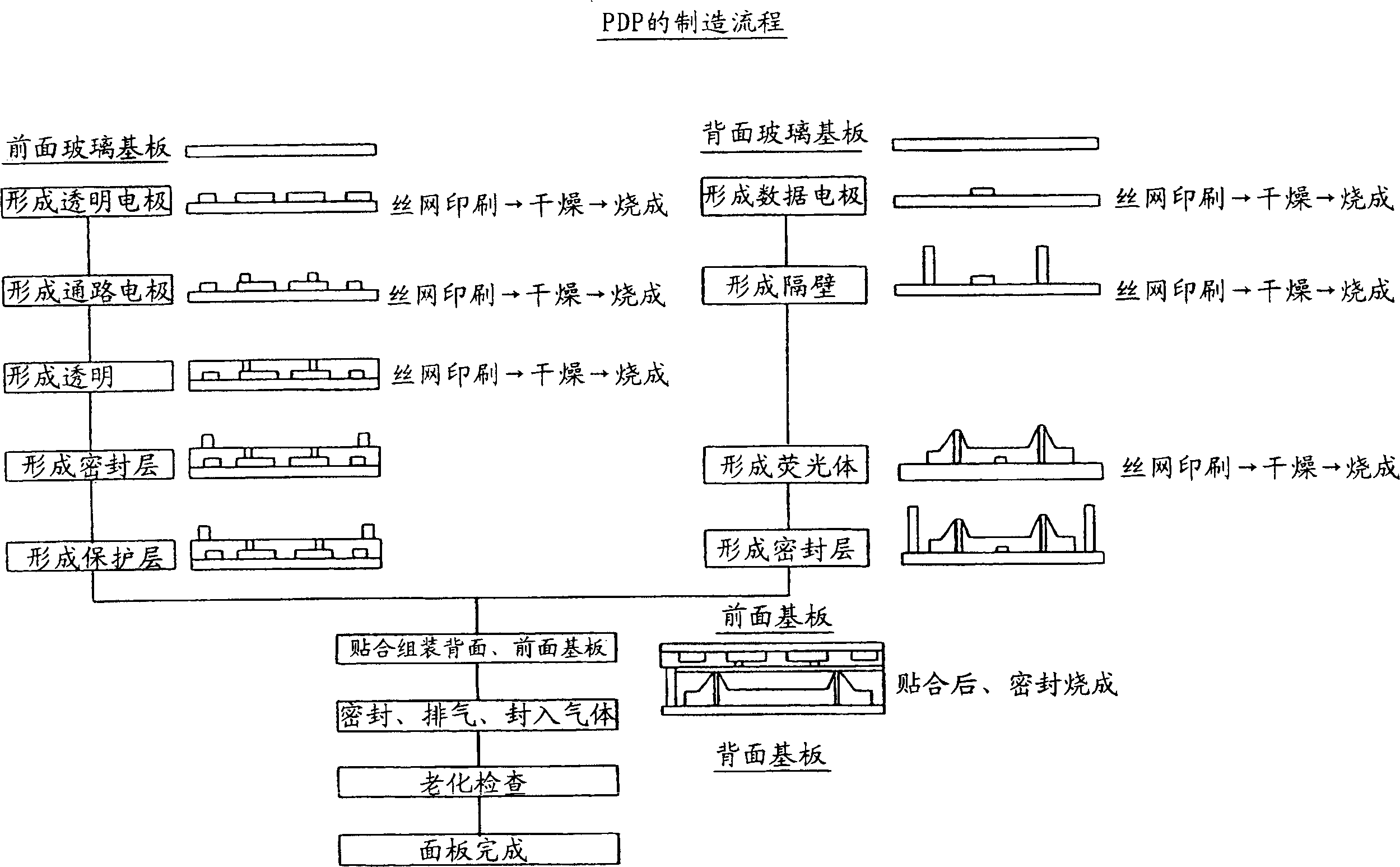

[0019] The heat treatment furnace used in the heat treatment method of the present invention includes a plurality of heating chambers divided in the conveying direction of the heat-treated object, and a conveying mechanism for conveying the heat-treated object to the adjacent heating chamber. Each heating chamber is provided with a heating mechanism that is divided into several at least in the conveyance direction of the object to be heat-processed. These divided heating mechanisms can be individually temperature controlled by independent control systems.

[0020] In addition, it is preferable that the above-mentioned conveying mechanism adopts a conveying mechanism of an intermittent feeding system that intermittently conveys the object to be heat-processed to the adjacent heating chamber. Here, "intermittently conveying" means repeatedly making the object to be heat-treated stationary in the n-th heating chamber from the entrance side of the furnace, and after performing hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com