Method for preparing uniform heat treatment wood by stacking

A stacking method and heat treatment chamber technology, which is applied to the preparation of uniform heat-treated wood, can solve the problems of high cost, obvious difference in material color, and uneven carbonization on the surface of heat-treated wood, so as to achieve high cost reduction, uniform overall color, and ease of use. The effect of supply and demand conflict

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

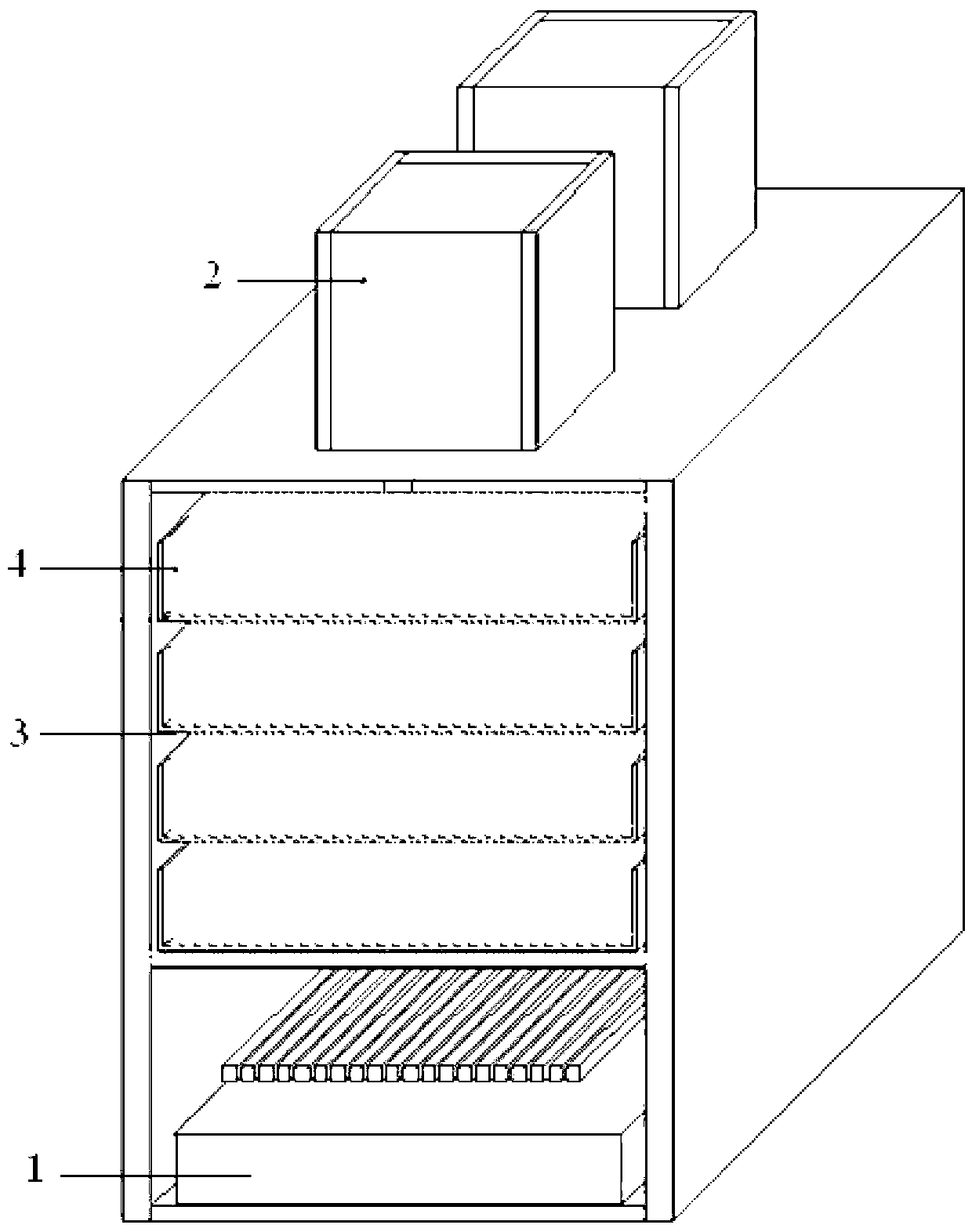

[0018] Specific Embodiment 1: In this embodiment, a method for preparing uniformly heat-treated wood by means of stacking is specifically completed according to the following steps:

[0019] 1. Select the wood board and dry the wood board until the moisture content is 8-13%;

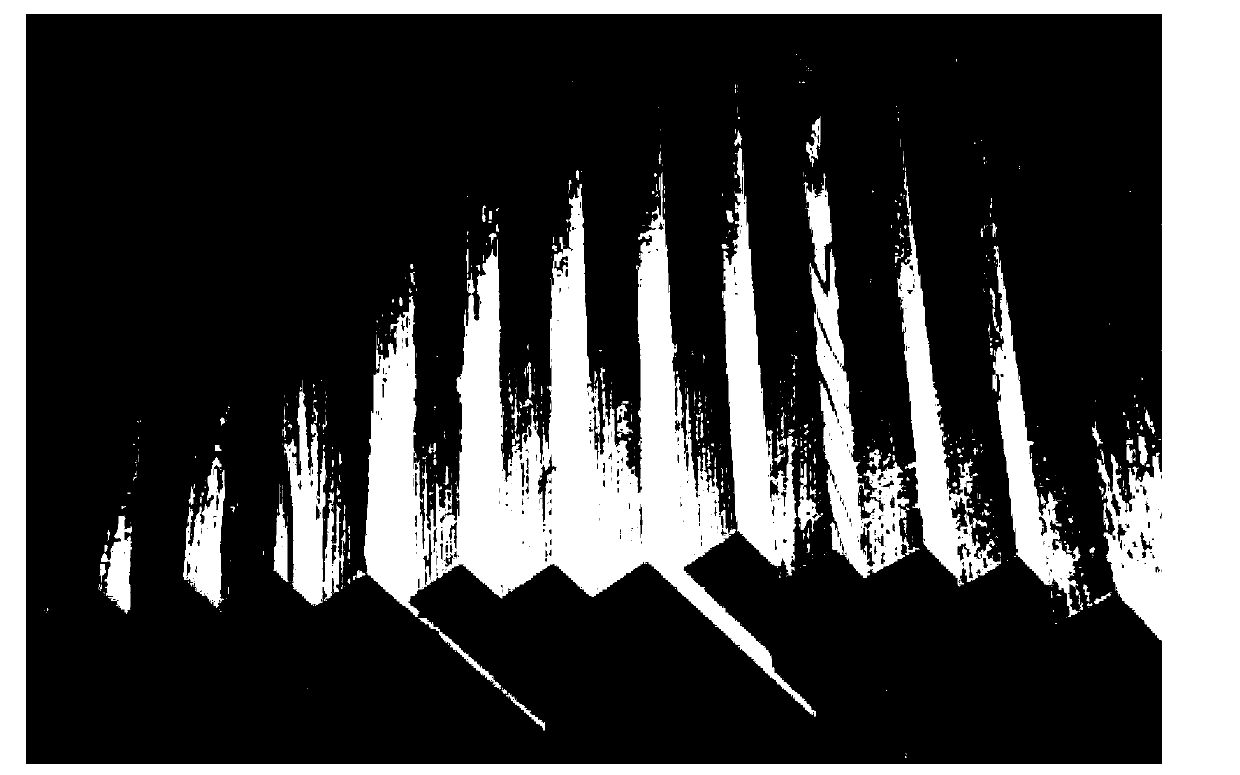

[0020] 2. Stack the timber panels processed in step 1 in the heat treatment chamber according to the horizontal vertical stacking method of the panels, and keep a gap of 1-10cm between the timber panels;

[0021] 3. Burn waste biomass materials, heat-treat the heat treatment chamber of the stacked wood panels in step 2, heat up to 150°C-240°C, and keep warm for 1-12 hours;

[0022] 4. Lower the temperature of the heat treatment chamber in the heat treatment step 3 to 30° C. to 60° C., take out the wood boards, and complete the stacking method to prepare evenly heat-treated wood.

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the wood boards selected in step 1 are not decayed or bent, and the length of the wood boards is 2m-6m. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 1 in that: in step 1, the wood board is dried to a moisture content of 10-12%. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com