Double-frequency equipment and process for normalizing rail welding seams

A rail and normalizing technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems that cannot break through 760 ℃, normalizing equipment and process technology can not meet the requirements of new standards, etc., to achieve simple setting and solve normalizing Effects of Temperature Uniformity Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

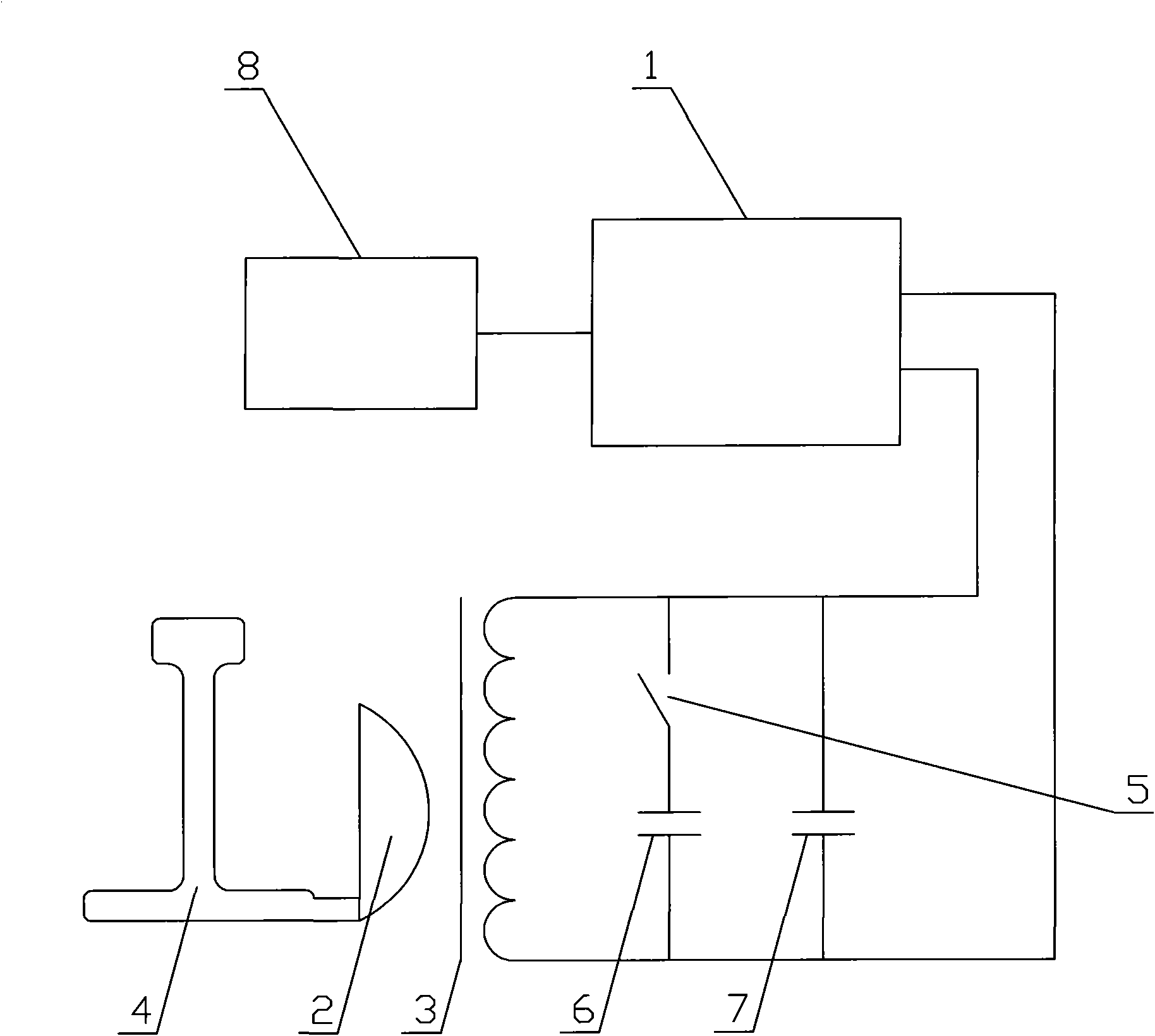

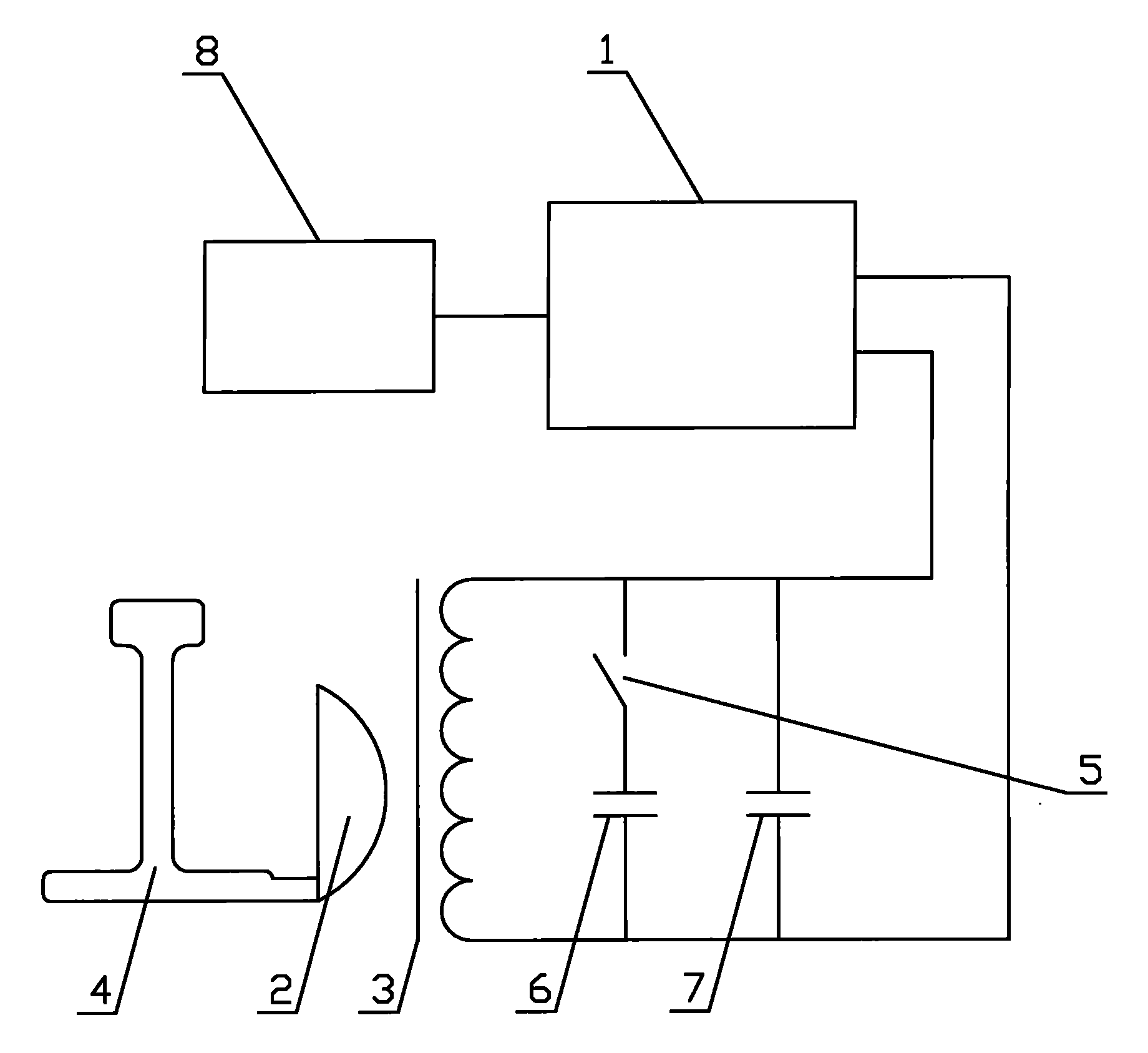

[0018] Embodiment 1: A dual-frequency normalizing equipment for rail welds, which includes an intermediate frequency power supply cabinet 1 and a transformer 2, wherein the transformer 2 includes a rail weld heating coil 3 and a load transformer 4, and it also includes an AC contactor 5 , low-frequency capacitor bank 6, high-frequency capacitor bank 7, PLC automatic controller 8, PLC automatic controller 8 is connected with intermediate frequency power supply cabinet 1, high-frequency capacitor bank 7 is connected with rail weld seam heating coil 3 in parallel, low-frequency capacitor bank 6 is connected with The AC contactor 5 is connected and connected in parallel with the rail welding seam heating coil 3 .

Embodiment 2

[0019] Embodiment 2: Using the dual-frequency normalizing equipment for rail welds in Embodiment 1, the following technological operations are performed.

[0020] According to the specific rail type, such as 50kg / m rail, a rail weld dual-frequency normalizing process includes the following production steps: (1) low-frequency heating; (2) high-frequency heating;

[0021] Wherein (1) low-frequency heating: set the power and frequency of the normalizing equipment, wherein the power is 60KW, the frequency is 1100Hz-1200Hz, and the temperature is 500°C-730°C to heat the weld of the rail;

[0022] (2) The PLC automatic controller of the rail weld dual-frequency normalizing equipment detects that the temperature of the bottom corner of the rail weld reaches the preset value of 730°C in the low-frequency band. If the temperature of the bottom corner of the detected rail weld is lower than the preset value in the low-frequency band If the fixed value is 730°C, the low-frequency heating...

Embodiment 3

[0025] Embodiment 3: Using the dual-frequency normalizing equipment for rail welds in Embodiment 1, the following technological operations are performed.

[0026] According to the specific rail type, such as Baotou Steel’s U71Mn material 60kg / m rail, a dual-frequency normalizing process for rail welds includes the following production steps: (1) low-frequency heating; (2) high-frequency heating;

[0027] Wherein (1) low-frequency heating: set the power and frequency of the normalizing equipment, wherein the power is 70KW, the frequency is 1000Hz-1100Hz, and the temperature is 500°C-730°C to heat the weld of the rail;

[0028] (2) The PLC automatic controller of the rail weld dual-frequency normalizing equipment detects that the temperature of the bottom corner of the rail weld reaches the preset value of 730°C in the low-frequency band. If the temperature of the bottom corner of the detected rail weld is lower than the preset value in the low-frequency band If the fixed value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com