Diamond bead string and manufacturing method thereof as well as rope saw without base body supporting layer

A diamond beading and diamond technology, which is applied in the direction of metal sawing equipment, stone processing equipment, metal processing equipment, etc., can solve the problems of affecting the service life of cutting stone, not being able to have enough, increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: a kind of preparation method of diamond bead, comprises the steps:

[0065] 1), the prepared metal pre-alloyed powder with a diameter of 0.5-20 microns (weight ratio is Co-20%, Ni-10%, Cu-28%, Fe-30%, Cr-3%, Sn-5 %, P-3%, Si-1%) and 3% of 40 / 50 mesh diamond are mixed for later use;

[0066] 2) Mix metal powder containing 70% diamond by volume, 15% paraffin, 14.5% polyethylene, and 0.5% stearic acid in a metal mixing tank under gas protection at a temperature of 200 degrees;

[0067] 3), the mixed raw material (granule mixture 7) is made into particles with a diameter of about 2mm;

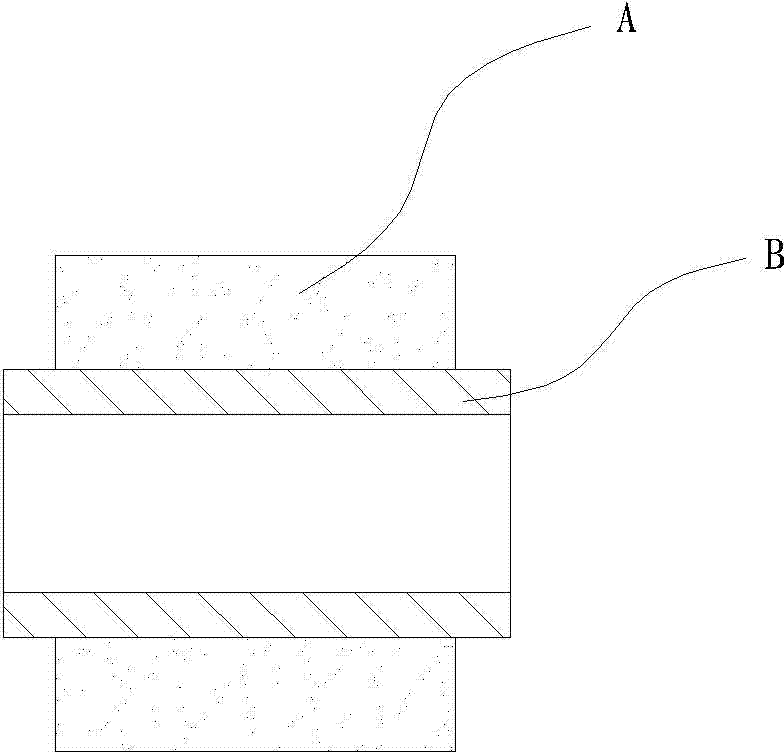

[0068] 4) Put the raw material particles 7 into the hot pressing mold with the cavity prepared, such as Figure 8 As shown, the hot stamping die is composed of a mold cover 8, a lower pressing head 9, an upper pressing head 10, and a product cavity 11. It is hot-pressed at 200 degrees, and after cooling and demoulding, it can form a diamond bead rough blank;

[0069] 5) Put...

Embodiment 2

[0071] Embodiment 2: a kind of preparation method of diamond bead, comprises the steps:

[0072] 1), the prepared metal pre-alloyed powder with a diameter of 0.5-20 microns (weight ratio is Co-60%, Ni-10%, Cu-10%, Fe-12%, Cr-3%, Sn-4 %, Si-1%) and 2.8% of 40 / 50 diamond are mixed for later use;

[0073] 2) Mix the diamond-containing metal powder with a small amount of paraffin and polyethylene at a temperature of 200 degrees;

[0074] 3) Make the mixed raw materials into particles with a diameter of about 2mm;

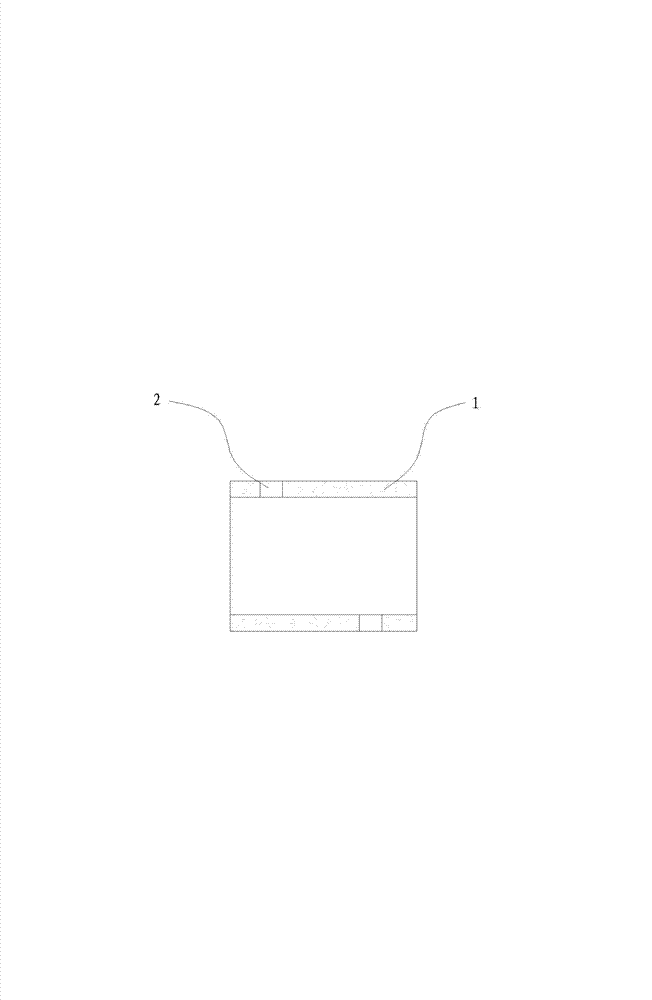

[0075] 4) Put the pellets into the barrel of the injection molding machine to heat, and inject them into the mold through the injection molding machine, such as Figure 9 , The mold is composed of a product cavity 11, a mold core 12, a sprue 13, a branch sprue 14, a template 15, and the like. After injection molding, the rough blank of diamond beads can be obtained;

[0076] 5) Put the cylindrical diamond bead rough blank into the degreasing furnace for degreasing; ...

Embodiment 3

[0078] Embodiment 3: a kind of preparation method of diamond bead, comprises the steps:

[0079]1), the prepared metal pre-alloyed powder with a diameter of 0.5-20 microns (weight ratio is Co-80%, Cu-15%, Sn-5%) and diamond with a mesh size of 40 / 50 (content 2.5%) ready after mixing;

[0080] 2) Mix metal powder containing diamond and a small amount of paraffin evenly at room temperature;

[0081] 3) Put the mixed raw materials into a cold press and cold press to obtain a cylindrical rough diamond bead;

[0082] 4) Put the rough blank into the diamond tool hydrogen sintering furnace, raise the temperature to 880 degrees, and sinter it at one time to obtain a finished product of diamond beads with a diameter of 4.5mm.

[0083] String the finished diamond beads into the wire rope, and then make a diamond wire saw.

[0084] In the above three embodiments, the diamond of the present invention can also be other superhard materials, such as cemented carbide, cubic boron nitride, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com