Wheel disc forging and manufacturing method thereof

A manufacturing process and forging technology, which is applied in the manufacturing field of key forgings of gas turbine units, can solve problems such as difficulty in ensuring the core flaw detection requirements of wheel disc forgings, difficulty in ensuring the purity of molten steel, lack of electroslag smelting process, etc., to solve the failure of flaw detection and mechanical properties, improving material hardenability and comprehensive mechanical properties, and the effect of reasonable chemical composition ratio

Active Publication Date: 2012-10-10

TONGYU HEAVY IND

View PDF5 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] The purpose of the present invention is to provide a wheel disc forging and its manufacturing process to solve the lack of electroslag smelting process in the prior art, which makes it difficult to ensure the purity of molten steel; lack of spinning forging process, so that the tensile stress in the core deformation process makes the material The core is not easy to be forged, and it is difficult to guarantee the core flaw detection requirements of the wheel forging

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

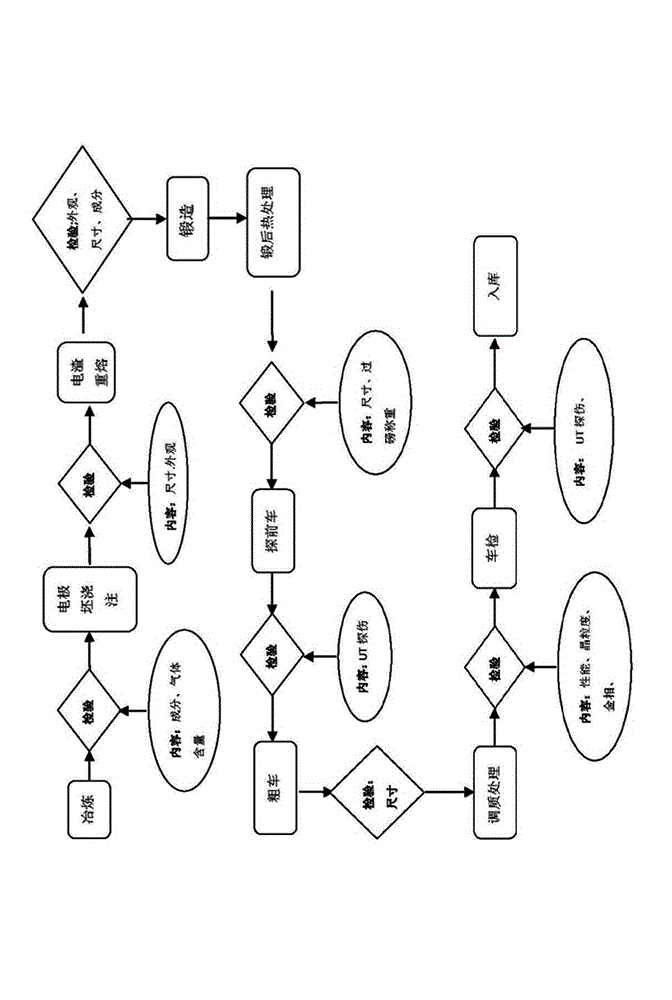

The invention discloses a wheel disc forging and a manufacturing method thereof and belongs to the technical field of mechanical manufacture. The manufacturing method further optimizes material components, controls the upper limits of C and Mn content, improves Ni content, reduces content of harmful P and S, reduces Si content and temper brittleness of Mn, utilizes an electroslag remelting process so that the purity of molten steel is improved, and utilizes post-forging heat treatment comprising two normalizing processes so that materials are further homogenized and grains are fined. Raw materials adopted by the manufacturing method comprise C, Mn, Si, P, S, Cr, Ni, Al, Cu and Fe. The manufacturing method comprises the following steps of electrode blank smelting, electroslag remelting smelting, steel ingot annealing, steel ingot forging, post-forging heat treatment, property heat treatment, and property and microstructure examination. The wheel disc forging obtained by the manufacturing method and the manufacturing method have the advantages that a ratio of chemical components is reasonable; material purity is high; forging effects on the core are good; density of the metal microstructure is good; and the problems that a wheel disc forging obtained by the existing manufacturing method is unqualified in the forging flaw detection and a mechanical property especially such as a material ductile-brittle transition temperature does not satisfy the requirement are solved.

Description

technical field [0001] The invention belongs to the technical field of mechanical manufacturing, and relates to a method for manufacturing a key forging of a gas turbine unit. Background technique [0002] 1. At present, gas turbine wheel disc forgings adopt different composition standards. There are generally large ranges of main element compositions such as C, Mn, Cr, and Mo, and internal control of main element compositions is required. [0003] 2. Traditional gas turbine wheel forgings adopt the following production process: [0004] (1) Smelting: EBT (electric arc furnace) + LF refining + VD vacuum degassing, pouring ingots; [0005] (2) Forging: forging with free forging press, drawing long, thick pier, and finished product, the total forging ratio is greater than 3; [0006] (3) Preliminary heat treatment: normalizing + tempering; [0007] (4) Performance heat treatment: quenching + tempering treatment [0008] 3. The disadvantages of traditional crafts are: [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/42C22B9/18C21D1/28C21D1/26C21D1/18B21J5/06B21J5/08

CPCY02P10/20

Inventor 司兴奎曹智勇孟扬呙文武杨清

Owner TONGYU HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com