Micro-emulsion biodiesel and preparation method thereof

A technology of biodiesel and microemulsion, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc. It can solve the problems of poor volatility, large amount of emulsifier, complex formula, etc., achieve thermodynamic stability, simple preparation method, and uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

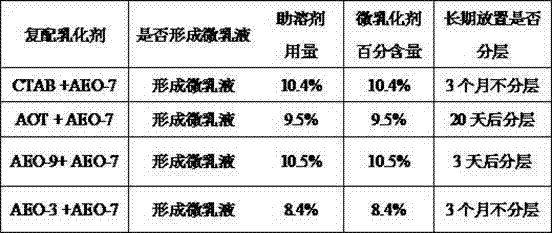

[0028] The screening of embodiment 1 emulsifier

[0029] In view of the influence of emulsifiers on the stability and quality of microemulsified biodiesel, this example optimizes and screens emulsifiers, which are specifically divided into the following steps.

[0030] 1. The effect of using a single emulsifier

[0031] First study the amount of microemulsion formed when a single emulsifier is used to determine the efficiency of the emulsifier.

[0032] The emulsifiers selected in this example are octylphenol polyoxyethylene ether (OP series), nonylphenol polyoxyethylene ether (TX series), fatty alcohol polyoxyethylene ether (AEO series), cetyl trimethyl Ammonium bromide (CTAB), dioctyl sodium sulfosuccinate (AOT), Span (Span series), Tween (Tween series), triethanolamine monooleate and fatty acid amides, etc.

[0033] Experimental method: After mixing different emulsifiers and co-solvents (n-butanol) at a mass ratio of 1:1, add them dropwise to biodiesel (the oil-water rat...

Embodiment 2

[0050] The formula of the microemulsified biodiesel in this embodiment is composed of 90% biodiesel, 2% compound emulsifier, 3% co-solvent and 5% water in terms of mass percentage.

[0051] Above-mentioned biodiesel is the biodiesel prepared from jatropha fruit oil;

[0052] The above compound emulsifier is a mixture of fatty alcohol polyoxyethylene ether AEO-3 and fatty alcohol polyoxyethylene ether AEO-7, wherein fatty alcohol polyoxyethylene ether AEO-3: the mass of fatty alcohol polyoxyethylene ether AEO-7 The ratio is 1:2.

[0053] The above co-solvent is a mixture of isopropanol and n-butanol, and the mixing volume ratio is 1:4.

[0054] The microemulsion biodiesel of the present embodiment, its preparation method is as follows:

[0055] First, according to the mass ratio, the fatty alcohol polyoxyethylene ether AEO-3 and the fatty alcohol polyoxyethylene ether AEO-7 are uniformly mixed to prepare a compound emulsifier, and then at room temperature, biodiesel, compound...

Embodiment 3

[0058] The formula of the microemulsified biodiesel in this embodiment is composed of 80% biodiesel, 6% compound emulsifier, 6% co-solvent and 8% water in terms of mass percentage.

[0059] Above-mentioned biodiesel is the biodiesel prepared from soybean oil;

[0060] The above compound emulsifier is a mixture of fatty alcohol polyoxyethylene ether AEO-3 and fatty alcohol polyoxyethylene ether AEO-7, wherein fatty alcohol polyoxyethylene ether AEO-3: the mass of fatty alcohol polyoxyethylene ether AEO-7 The ratio is 1:4.

[0061] The above-mentioned co-solvent is a mixture of isobutanol and n-pentanol, and the volume ratio of the mixture is 3:2.

[0062] The microemulsion biodiesel of the present embodiment, its preparation method is as follows:

[0063] First, according to the mass ratio, the fatty alcohol polyoxyethylene ether AEO-3 and the fatty alcohol polyoxyethylene ether AEO-7 are uniformly mixed to prepare a compound emulsifier, and then at room temperature, biodiese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com