Preparation method of waterborne epoxy composite anticorrosive coating

A technology of anti-corrosion coatings and water-based epoxy, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of decreased strength and barrier properties, and achieves improved anti-corrosion and strength, high stability, and brushing The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

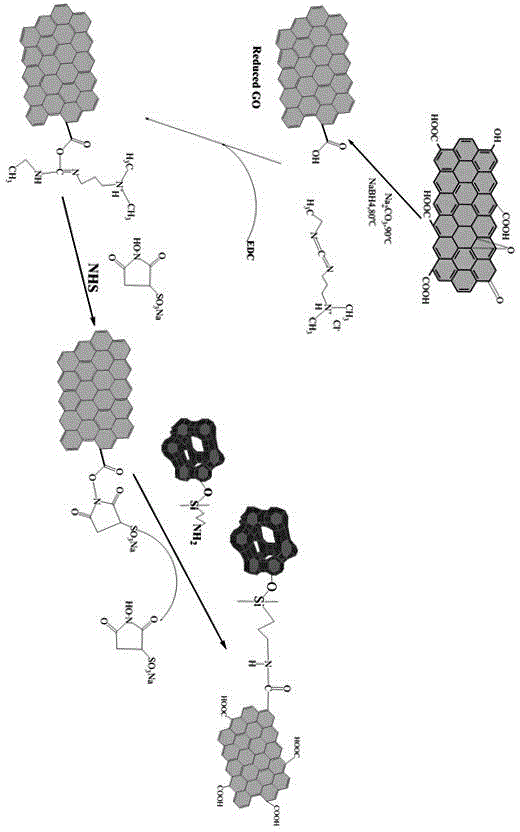

[0026] (1) Zeolite grafted graphene:

[0027] 1) Amination of zeolite: Put 4g of zeolite into 50ml of organic solvent, heat up to 80°C under stirring, then add 6ml of silane coupling agent, continue to reflux for 8h, cool to room temperature, wash and filter, and heat up to 80°C in hot air at 60°C medium dry;

[0028] 2) Integration of zeolite and graphene: Ultrasonic dispersion of reduced graphene in 100ml distilled water. A 10mmol / 5mmol EDC / NHS aqueous solution was prepared and added to the dispersed graphene. After activation for 0.5 hours, an aminated zeolite was added, stirred at room temperature for 6 hours, and centrifugally dried to obtain graphene grafted with zeolite.

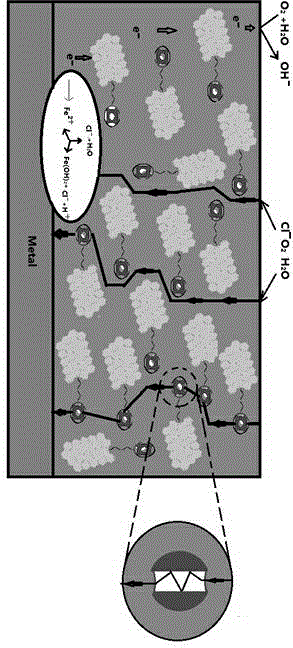

[0029] (2) Preparation of anti-corrosion coating:

[0030] 1) Take 100 parts of water-based epoxy resin and 100 parts of water,

[0031] 2) Take 35 parts of zeolite-grafted graphene filler, add it to the above resin system, and disperse it in a ball mill for 1 hour. 3) Take 50 parts of water-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com