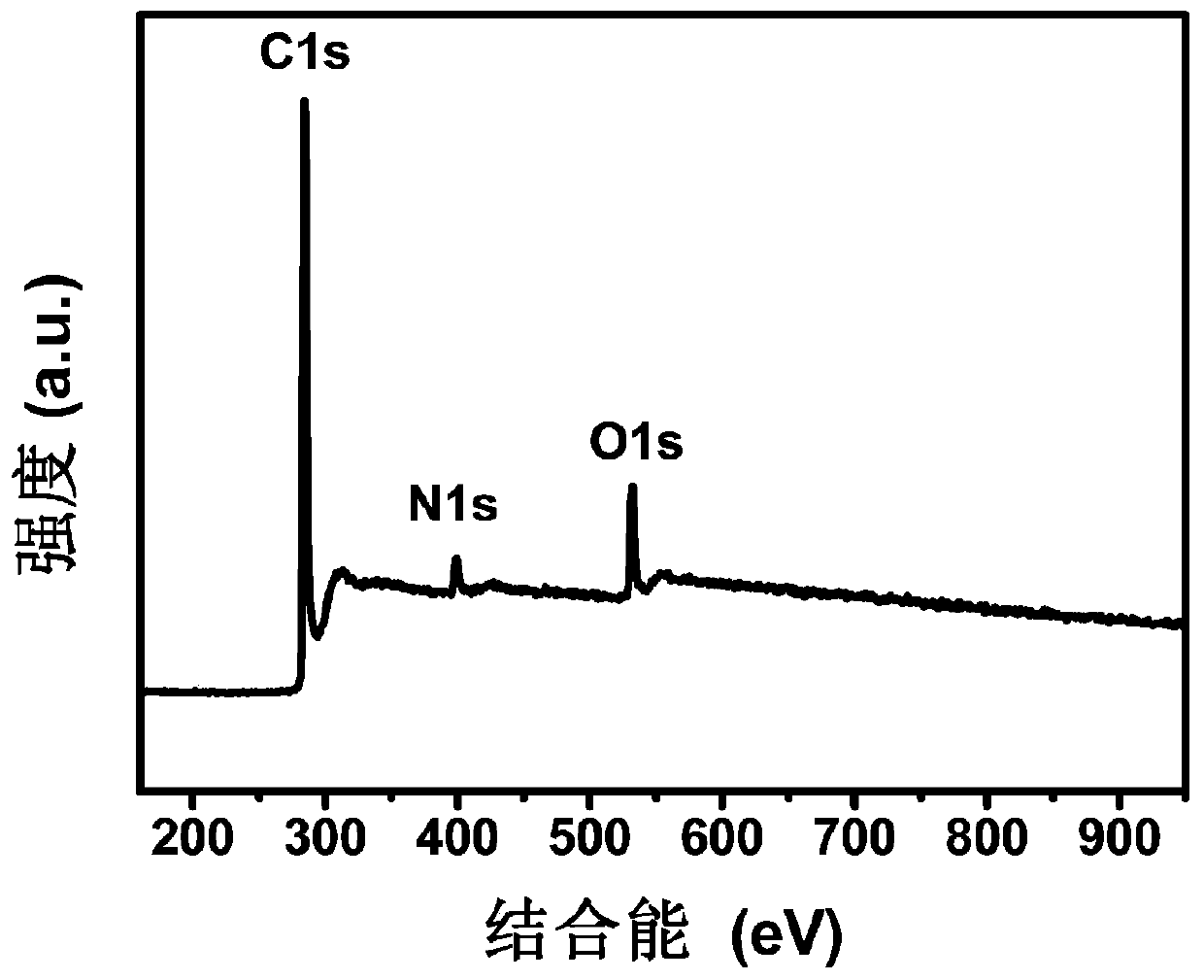

A scalable method for the fabrication of high-density n-doped graphene materials

A high-density, graphene technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problem that high-density graphene materials are difficult to mass-produce, and achieve simple and easy operation steps and high packing density , to prevent the effect of re-stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of preparation method of the graphene material of high-density N doping, comprises steps as follows:

[0039] (1) Dilute the GO dispersion to a concentration of 3mg mL -1 The dispersion liquid is uniformly dispersed by ultrasonic, and is used for standby; the PEI solution is diluted to a solution with a concentration of 0.1 wt.%, and is uniformly dispersed by ultrasonic, and is used for standby.

[0040] (2) Take 10 mL of GO dispersion in the reactor for magnetic stirring, slowly drop 1 mL of PEI solution into the GO dispersion, and the GO-PEI complex is immediately precipitated.

[0041](3) After the dropwise addition, the reaction system was aged, and the GO-PEI complex precipitated and gathered at the bottom of the reaction vessel, and the unreacted PEI was removed by vacuum filtration and washing operations.

[0042] (4) The filtered product was dried at room temperature for 12 hours, and a high-density GO-PEI composite material was obtained through capillar...

Embodiment 2

[0045] A kind of preparation method of the graphene material of high-density N doping, comprises steps as follows:

[0046] (1) Dilute the GO dispersion to a concentration of 0.1mg mL -1 The dispersion liquid is uniformly dispersed by ultrasonic, and is used for standby; the PEI solution is diluted to a solution with a concentration of 0.01wt.%, and is uniformly dispersed by ultrasonic, and is used for standby.

[0047] (2) Take 10L of GO dispersion in the reactor for magnetic stirring, slowly drop 1L of PEI solution into the GO solution, and the GO-PEI complex is immediately precipitated.

[0048] (3) After the dropwise addition, the reaction system was aged, and the GO-PEI complex precipitated and gathered at the bottom of the reaction vessel, and the unreacted PEI was removed by vacuum filtration and washing operations.

[0049] (4) The filtered product was dried at room temperature for 24 hours, and a high-density GO-PEI composite material was obtained through capillary s...

Embodiment 3

[0052] A kind of preparation method of the graphene material of high-density N doping, comprises steps as follows:

[0053] (1) Dilute the GO dispersion to a concentration of 5 mg mL -1 The dispersion liquid is uniformly dispersed by ultrasonic, and is used for standby; the PEI solution is diluted to a solution with a concentration of 10wt.%, and is uniformly dispersed by ultrasonic, and is used for standby.

[0054] (2) Take 10 mL of GO dispersion in the reactor for magnetic stirring, slowly drop 1 mL of PEI solution into the GO dispersion, and the GO-PEI complex is immediately precipitated.

[0055] (3) After the dropwise addition, the reaction system was aged, and the GO-PEI complex precipitated and gathered at the bottom of the reaction vessel, and the unreacted PEI was removed by vacuum filtration and washing operations.

[0056] (4) The filtered product was dried at room temperature for 12 hours, and a high-density GO-PEI composite material was obtained through capillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com