Preparation method of porous graphene/carbon nanotube flexible self-supporting film material

A porous graphene and carbon nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of cumbersome preparation process, difficult industrial production, long synthesis cycle, etc. The effect of high catalytic performance, high specific surface area, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of porous graphene / carbon nanotube flexible self-supporting film material loaded with Pt nanoparticles, including the following steps:

[0048] (1) Add 7mL GO dispersion (10mg mL -1 ) Dissolve in 28mL deionized water, ultrasonically disperse to a uniform solution, and set aside;

[0049] Dissolve 1.4 mL of PS solution (2.5% (W / V)) in 2.1 mL of deionized water, mix and sonicate to a uniform solution to obtain a GO-PS mixture;

[0050] (2) Ultrasound 3.34mL of SWCNT dispersion (0.15wt%), add it to the above-mentioned GO-PS mixture, mix and stir for 15 minutes, to obtain GO-PS-SWCNT mixture;

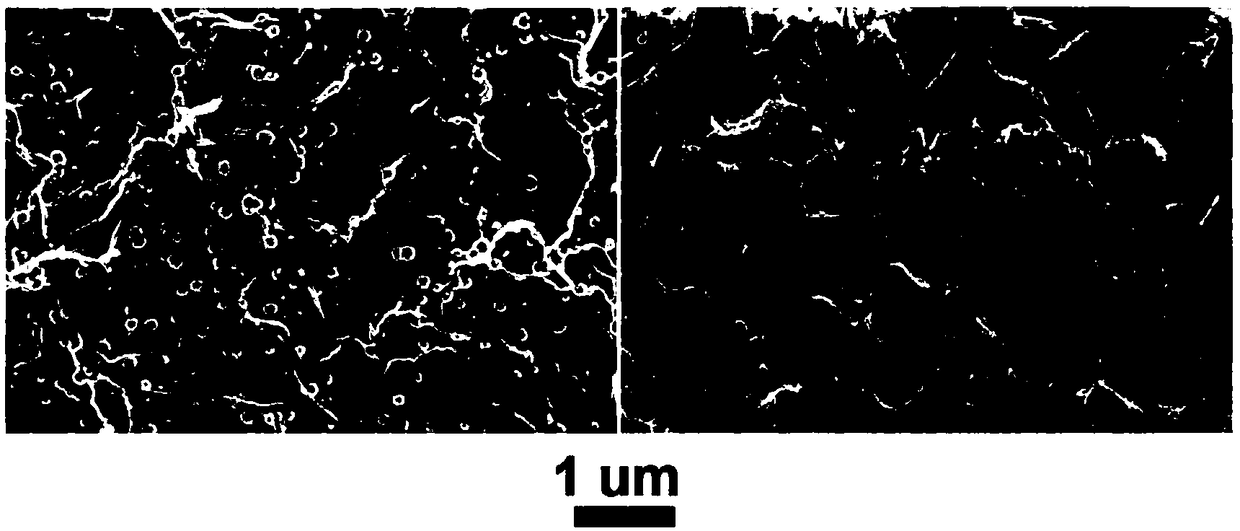

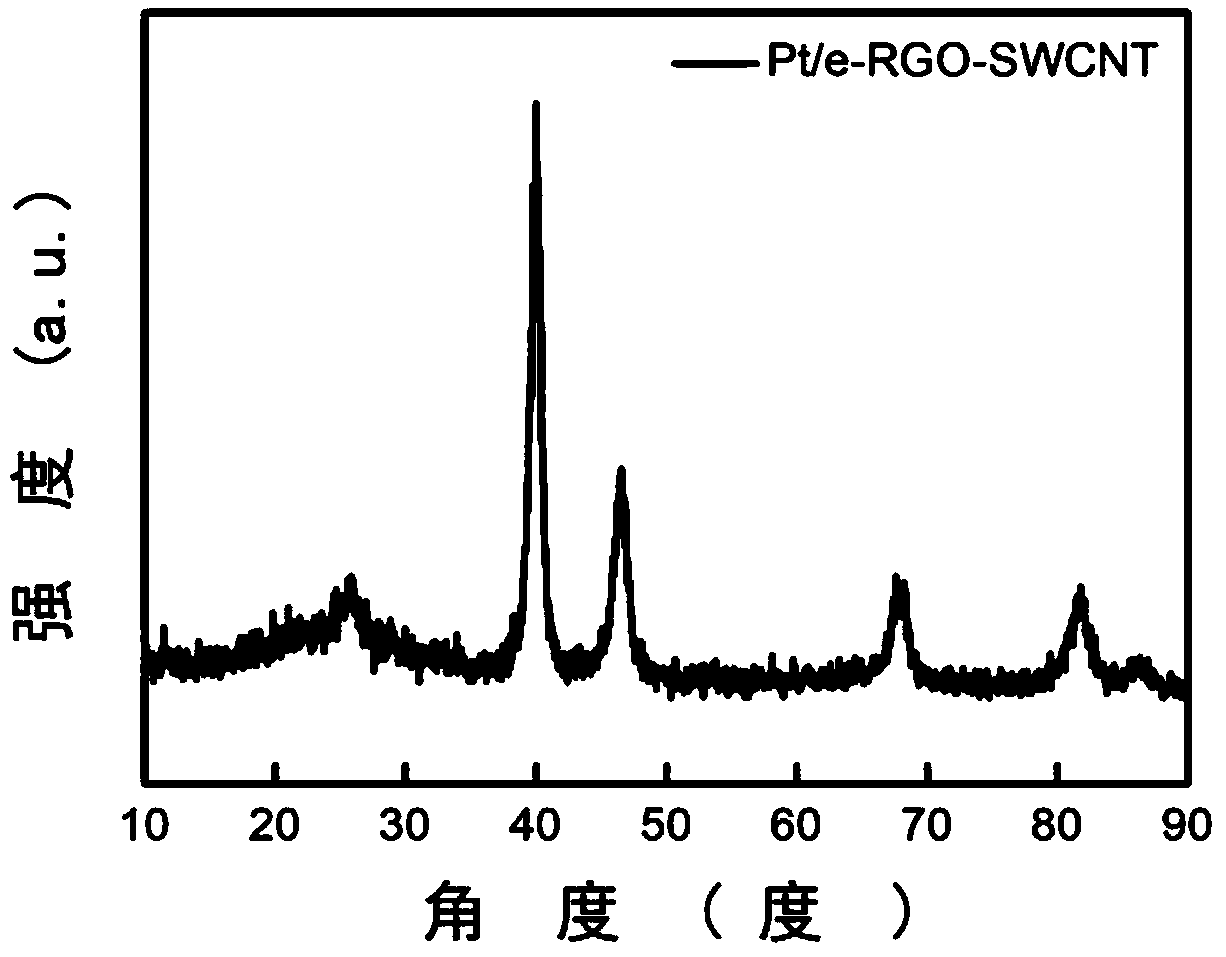

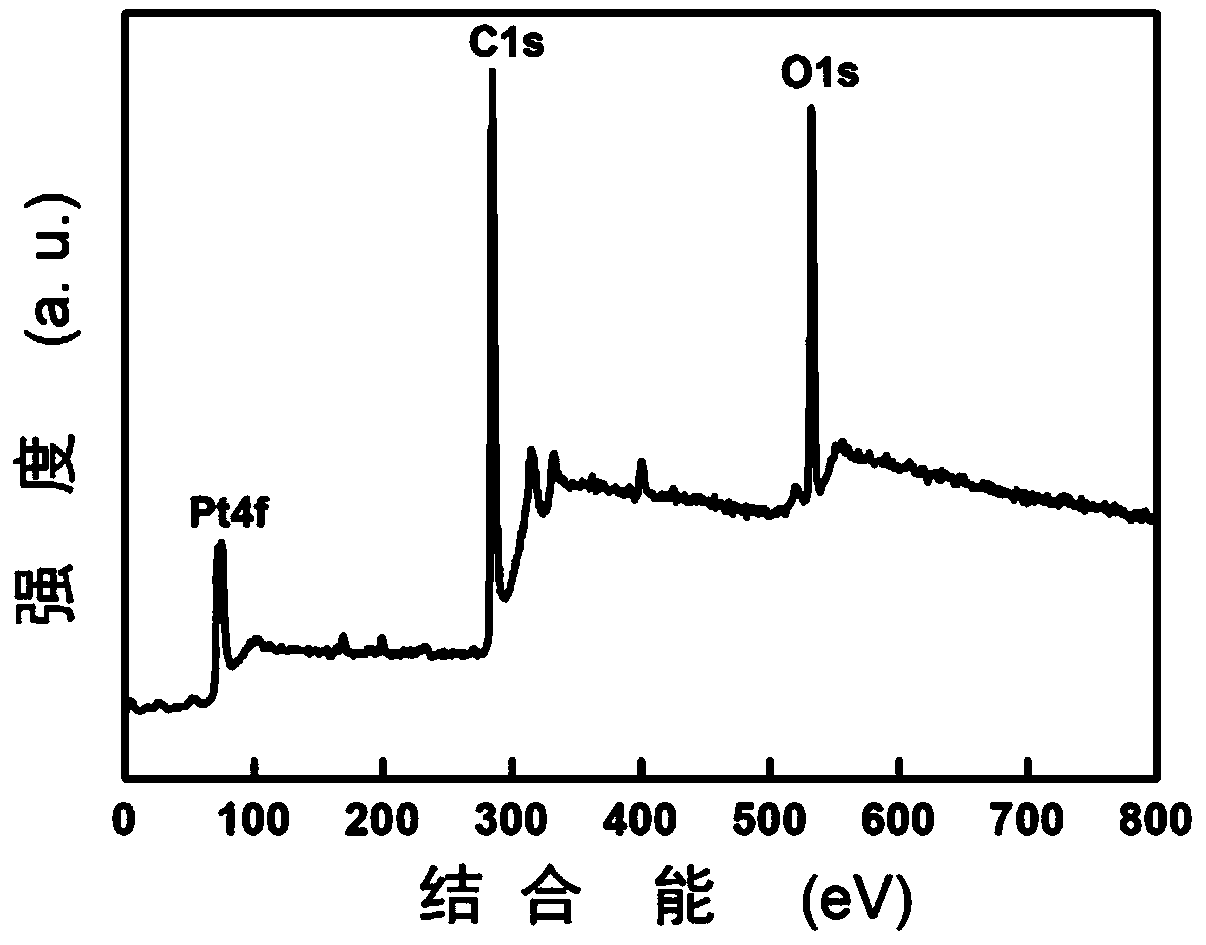

[0051] (3) Vacuum filter the GO-PS-SWCNT mixture to form a film, heat the membrane composite material to the calcination temperature in Ar protective gas for high-temperature calcination, the calcination temperature is 500 ℃, the heating rate is 10 ℃ min -1 , Calcining time is 1h, calcining to obtain e-RGO-SWCNT flexible film;

[0052] (4) The electrochemical deposition me...

Embodiment 2

[0057] A preparation method of porous graphene / carbon nanotube flexible self-supporting film material loaded with Pt nanoparticles, including the following steps:

[0058] (1) Add 7mL GO dispersion (5mg mL -1 ) Dissolve in 28mL of deionized water and ultrasonically disperse to a homogeneous solution for use; Dissolve 1.4mL of PS solution (1%(W / V)) into 2.1mL of deionized water, mix and sonicate to a uniform solution to obtain a GO-PS mixture ;

[0059] (2) Ultrasound 3.34mL of SWCNT dispersion (0.1wt%), add it to the above-mentioned GO-PS mixture, mix and stir for 15 minutes, to obtain GO-PS-SWCNT mixture;

[0060] (3) Vacuum filter the GO-PS-SWCNT mixture to form a film, and heat the membrane composite material to the calcination temperature in Ar protective gas for high-temperature calcination. The calcination temperature is 300℃, and the heating rate is 10℃ min. -1 , Calcining time is 5h, calcining to obtain e-RGO-SWCNT flexible film;

[0061] (4) Pt (0.005 mg) was deposited on the...

Embodiment 3

[0063] A method for preparing porous graphene / carbon nanotube flexible self-supporting membrane material loaded with Pt nanoparticles, including the following steps:

[0064] (1) Add 7mL GO dispersion (8mg mL -1 ) Dissolve in 28mL of deionized water and ultrasonically disperse to a homogeneous solution for use; Dissolve 1.4mL of PS solution (3% (W / V)) into 2.1mL of deionized water, mix and sonicate to a uniform solution to obtain GO-PS mixture ;

[0065] (2) Ultrasound 3.34mL of SWCNT dispersion (0.3wt%), add it to the above-mentioned GO-PS mixture, mix and stir for 15 minutes, to obtain GO-PS-SWCNT mixture;

[0066] (3) Vacuum filter the GO-PS-SWCNT mixture to form a film, heat the membrane composite material to the calcination temperature in Ar protective gas for high-temperature calcination, the calcination temperature is 400 ℃, the heating rate is 10 ℃ min -1 , Calcining time is 3h, calcined to obtain e-RGO-SWCNT flexible film;

[0067] (4) Pt (0.015mg) was deposited on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com