Copper pyrovanadate/nitrogen-doped graphene composite material and preparation method and application thereof

A technology of nitrogen-doped graphene and composite materials, which is applied in the field of nanomaterials, can solve the problems of electrode electrochemical instability, low first-time Coulombic efficiency, and fast capacity decay, so as to prevent volume expansion/shrinkage and aggregation, and the preparation method is simple Efficient and prevents performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

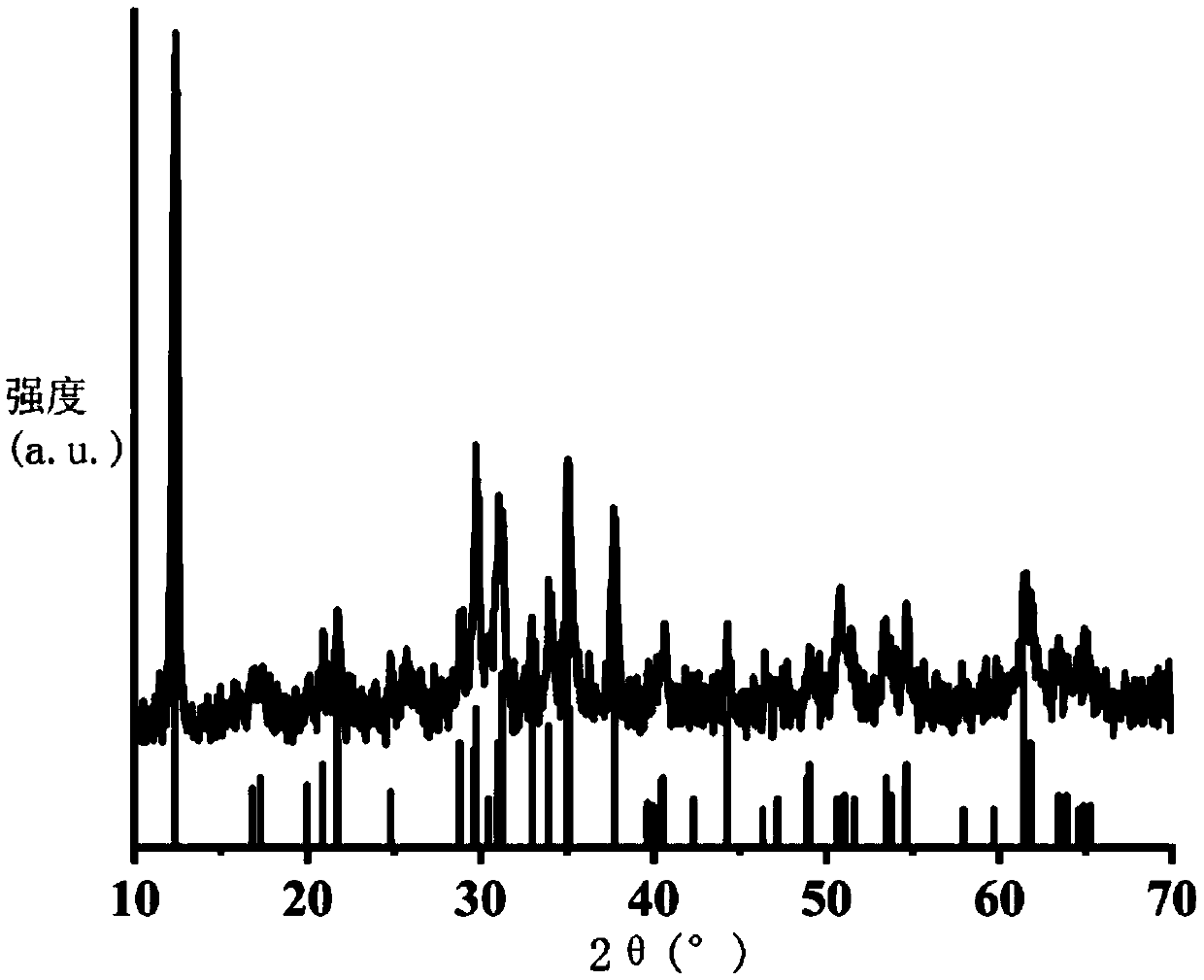

[0039] This embodiment provides a copper pyrovanadate / nitrogen-doped graphene composite material and a preparation method of the copper pyrovanadate / nitrogen-doped graphene composite material.

[0040] The copper pyrovanadate / nitrogen-doped graphene composite material described in this embodiment includes graphene and copper pyrovanadate grown on the surface of graphene, has a three-dimensional mesoporous structure, and the specific preparation steps are as follows:

[0041] (1) Preparation of graphene oxide (GO): place the flask in an ice bath, mix 5g of graphite powder with 180mL of concentrated sulfuric acid (98wt.% H 2 SO 4 ) into the flask, and kept stirring, so that the graphite powder was completely dispersed in the concentrated sulfuric acid solution. Then slowly add 2.5g NaNO to the flask 3 and 20g KMnO 4, keep the ice-water bath environment during this feeding process, and continue to stir for 1h. Thereafter, the flask was transferred to an oil bath, and the temp...

Embodiment 2

[0049] This embodiment provides a copper pyrovanadate / nitrogen-doped graphene composite material and a preparation method of the copper pyrovanadate / nitrogen-doped graphene composite material.

[0050] The copper pyrovanadate / nitrogen-doped graphene composite material described in this embodiment includes graphene and copper pyrovanadate grown on the surface of graphene, has a three-dimensional mesoporous structure, and the specific preparation steps are as follows:

[0051] (1) Preparation of graphene oxide (GO): place the flask in an ice bath, mix 5g of graphite powder with 180mL of concentrated sulfuric acid (98wt.% H 2 SO 4 ) into the flask, and kept stirring, so that the graphite powder was completely dispersed in the concentrated sulfuric acid solution. Then slowly add 2.5g NaNO to the flask 3 and 20g KMnO 4 , keep the ice-water bath environment during this feeding process, and continue to stir for 1h. Thereafter, the flask was transferred to an oil bath, and the tem...

Embodiment 3

[0055] This embodiment provides a copper pyrovanadate / nitrogen-doped graphene composite material and a preparation method of the copper pyrovanadate / nitrogen-doped graphene composite material.

[0056] The copper pyrovanadate / nitrogen-doped graphene composite material described in this embodiment includes graphene and copper pyrovanadate grown on the surface of graphene, has a three-dimensional mesoporous structure, and the specific preparation steps are as follows:

[0057] (1) Preparation of graphene oxide (GO): place the flask in an ice bath, mix 5g of graphite powder with 180mL of concentrated sulfuric acid (98wt.% H 2 SO 4 ) into the flask, and kept stirring, so that the graphite powder was completely dispersed in the concentrated sulfuric acid solution. Then slowly add 2.5g NaNO to the flask 3 and 20g KMnO 4 , keep the ice-water bath environment during this feeding process, and continue to stir for 1h. Thereafter, the flask was transferred to an oil bath, and the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com