Electrostatic self-assembly spherical molybdenum trioxide/MXene composite material as well as preparation method and application thereof

A technology of electrostatic self-assembly and molybdenum trioxide, applied in nanotechnology, electrochemical generators, circuits, etc. for materials and surface science, to achieve easy contact, excellent charge-discharge cycle performance and rate performance, and high specific capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

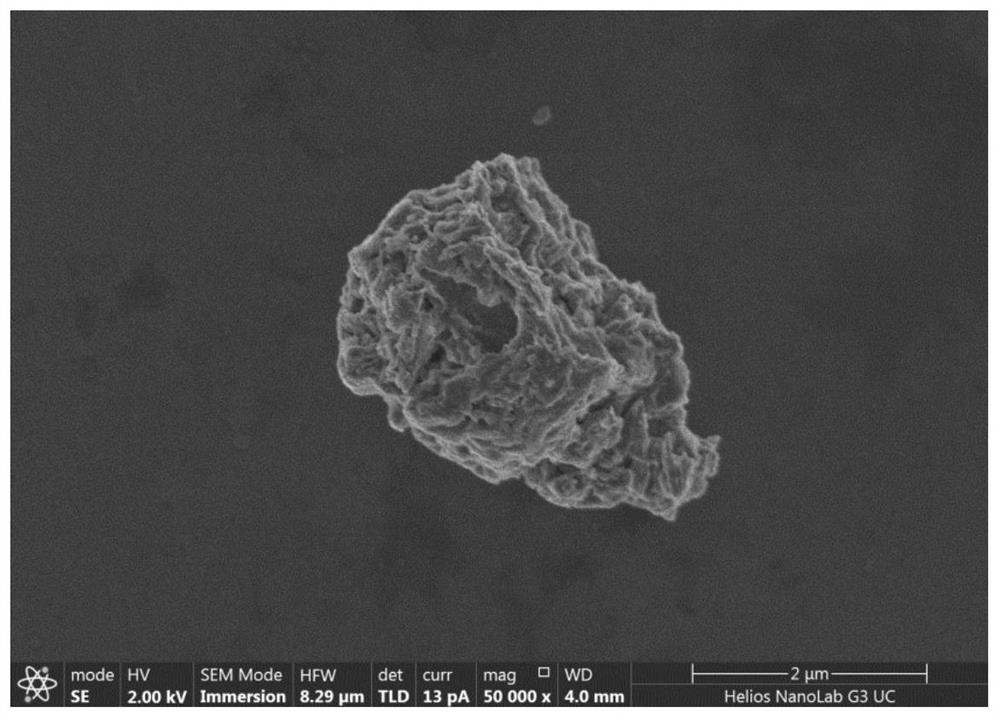

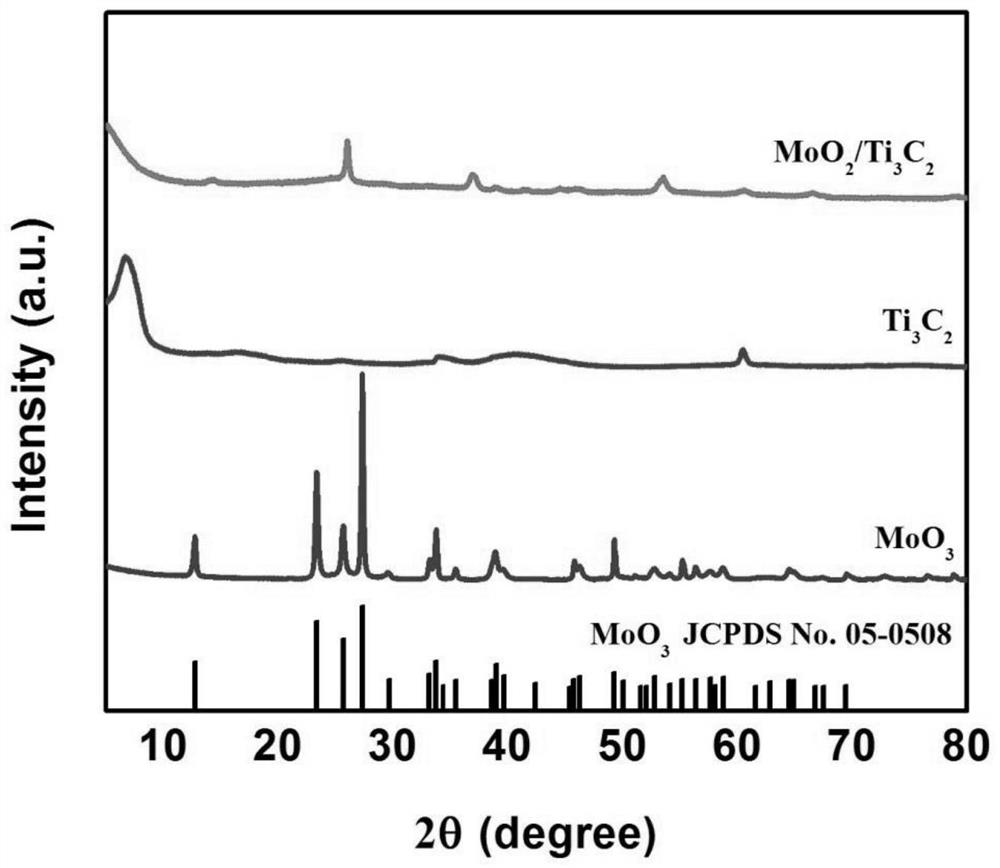

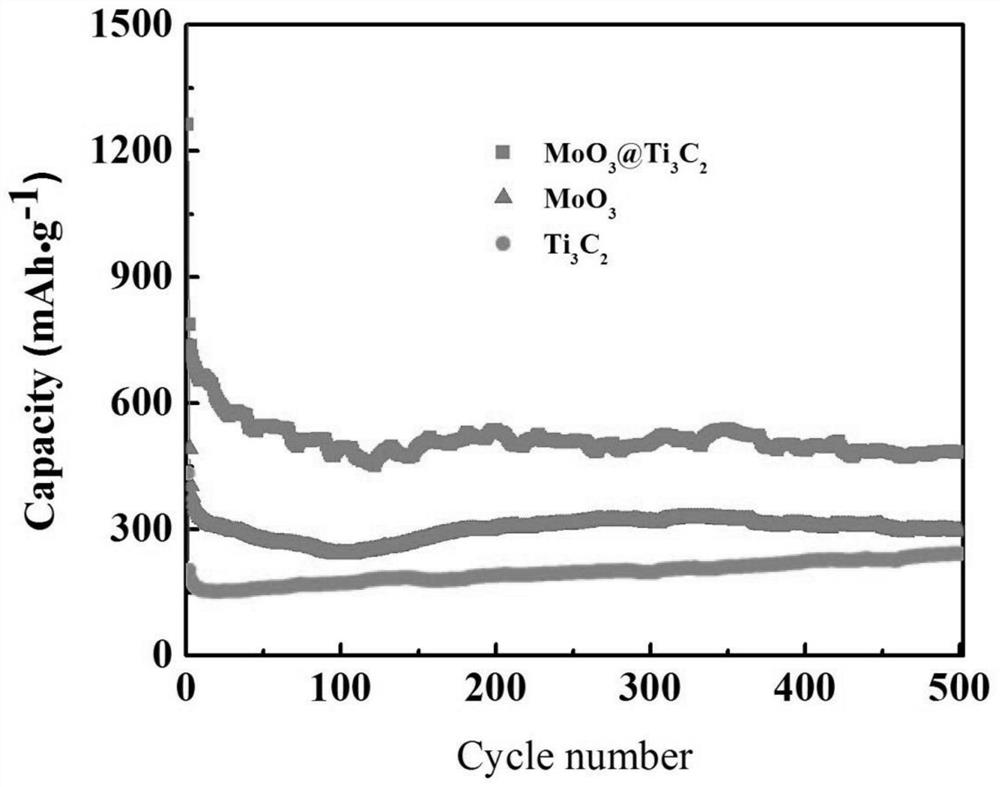

Embodiment 1

[0033] 1. Add 1mmol MoO 2 (acac) 2 Add to 50mL ethanol, stir to obtain A solution;

[0034] 2. Pour the solution A described in step 1 into a stainless steel reaction kettle, then put it into a blast drying oven and heat it to 200°C for 48 hours, then carry out centrifugal washing after cooling in the furnace, and obtain solid B after drying;

[0035] 3. Put the solid B described in step 2 into a rapid heating resistance furnace, and heat it up to 450°C for 3 hours in an air atmosphere to obtain solid C;

[0036] 4. After diluting 0.1ml of 20wt.% polydiallyldimethylammonium chloride (PDDA) solution with 200mL of deionized water, put 200mg of solid C obtained in step 3 into it and stir for a while, then wash by centrifugation To obtain solid D, add deionized water to a concentration of 1 mg / mL, and stir evenly to obtain solution E;

[0037] 5. Measure the aqueous solution containing 25mg of MXene, add water to dilute it to 25mL, and add it to the 225mL solution E obtained in s...

Embodiment 2

[0040] 1. Add 1mmol MoO 2 (acac) 2 Add to 50mL ethanol, stir to obtain A solution;

[0041] 2. Pour the solution A described in step 1 into a stainless steel reaction kettle, then put it into a blast drying oven and heat it to 200°C for 48 hours, then carry out centrifugal washing after cooling in the furnace, and obtain solid B after drying;

[0042] 3. Put the solid B described in step 2 into a rapid heating resistance furnace, and heat it up to 450°C for 3 hours in an air atmosphere to obtain solid C;

[0043] 4. After diluting 0.1ml of 20wt.% polydiallyldimethylammonium chloride (PDDA) solution with 200mL of deionized water, put 200mg of solid C obtained in step 3 into it and stir for a while, then wash by centrifugation To obtain solid D, add deionized water to a concentration of 1 mg / mL, and stir evenly to obtain solution E;

[0044] 5. Measure the aqueous solution containing 50mg of MXene, add water to dilute to 50mL, and add it to the 200mL solution E obtained in st...

Embodiment 3

[0047] 1. Add 1mmol MoO 2 (acac) 2 Add to 50mL ethanol, stir to obtain A solution;

[0048] 2. Pour the solution A described in step 1 into a stainless steel reaction kettle, then put it into a blast drying oven and heat it to 200°C for 48 hours, then carry out centrifugal washing after cooling in the furnace, and obtain solid B after drying;

[0049] 3. Put the solid B described in step 2 into a rapid heating resistance furnace, and heat it up to 450°C for 3 hours in an air atmosphere to obtain solid C;

[0050] 4. After diluting 0.1ml of 20wt.% polydiallyldimethylammonium chloride (PDDA) solution with 200mL of deionized water, put 200mg of solid C obtained in step 3 into it and stir for a while, then wash by centrifugation To obtain solid D, add deionized water to a concentration of 1 mg / mL, and stir evenly to obtain solution E;

[0051] 5. Measure the aqueous solution containing 125mg of MXene, add water to dilute it to 125mL, and add it to the 125mL solution E obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com