Method for producing lead bullion by means of copper dross side-blown smelting

A copper scum, crude lead technology, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

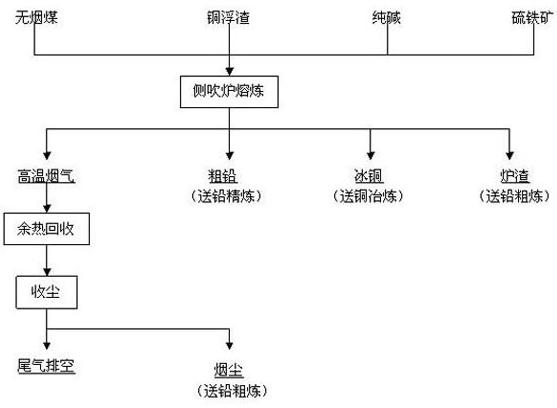

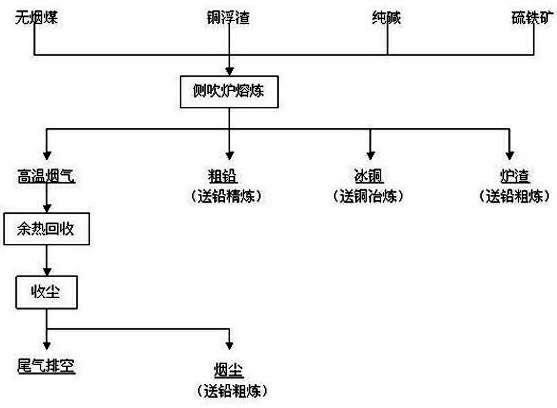

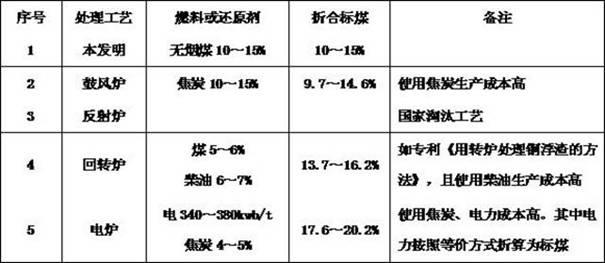

[0022] like figure 1 shown, at 2.5m 2 In the side-blowing furnace, copper scum (Pb80%, Cu5%), soda ash, pyrite (containing S25%) are mixed according to the ratio of 100:8:6, and the temperature in the furnace is controlled at 700 °C when feeding. Feed 45 tons in 2 hours and enter the molten pool of the side-blowing furnace for reduction smelting. At the same time, the anthracite (containing 81% C, and more than 80% of which the particle size is less than 0.127mm) is uniformly blown in by high-pressure air.

[0023] The melting temperature is 700°C at the beginning, and after 2 hours, the temperature is increased to 1100°C, and after 3 hours, the metallic lead and the combined lead in the copper scum are all smelted into crude lead.

[0024] After clarification and separation for 1 hour, the crude lead and matte are first released by siphon, and then the slag port is opened to release the slag. 2 Concentration 300mg / m 3 ).

[0025] The amount of anthracite in the whole pro...

Embodiment 2

[0027] at 2.5m 2 In the side-blown furnace, copper scum (Pb60%, Cu10%), soda ash, pyrite (containing S25%) were mixed according to the ratio of 100: 10:8, and the temperature in the furnace was controlled at 800 °C when feeding. Feed 35 tons in 1 hour into the molten pool of side blowing furnace for reduction smelting. At the same time, anthracite (containing C81%) is blown evenly with high-pressure air.

[0028] The melting temperature is 800°C at the beginning, and the temperature is increased to 1100°C after 1 hour, and the metallic lead and combined lead in the copper scum are all smelted into crude lead after 2 hours.

[0029] After clarification and separation for 40 minutes, the crude lead and matte are first released by siphon, and then the slag port is opened to release the slag. 2 Concentration 280mg / m 3 ).

[0030] The amount of anthracite in the whole process is 12% of the amount of copper scum. The output of crude lead (containing Pb97.2%, Cu0.4%) was 16.7t, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com