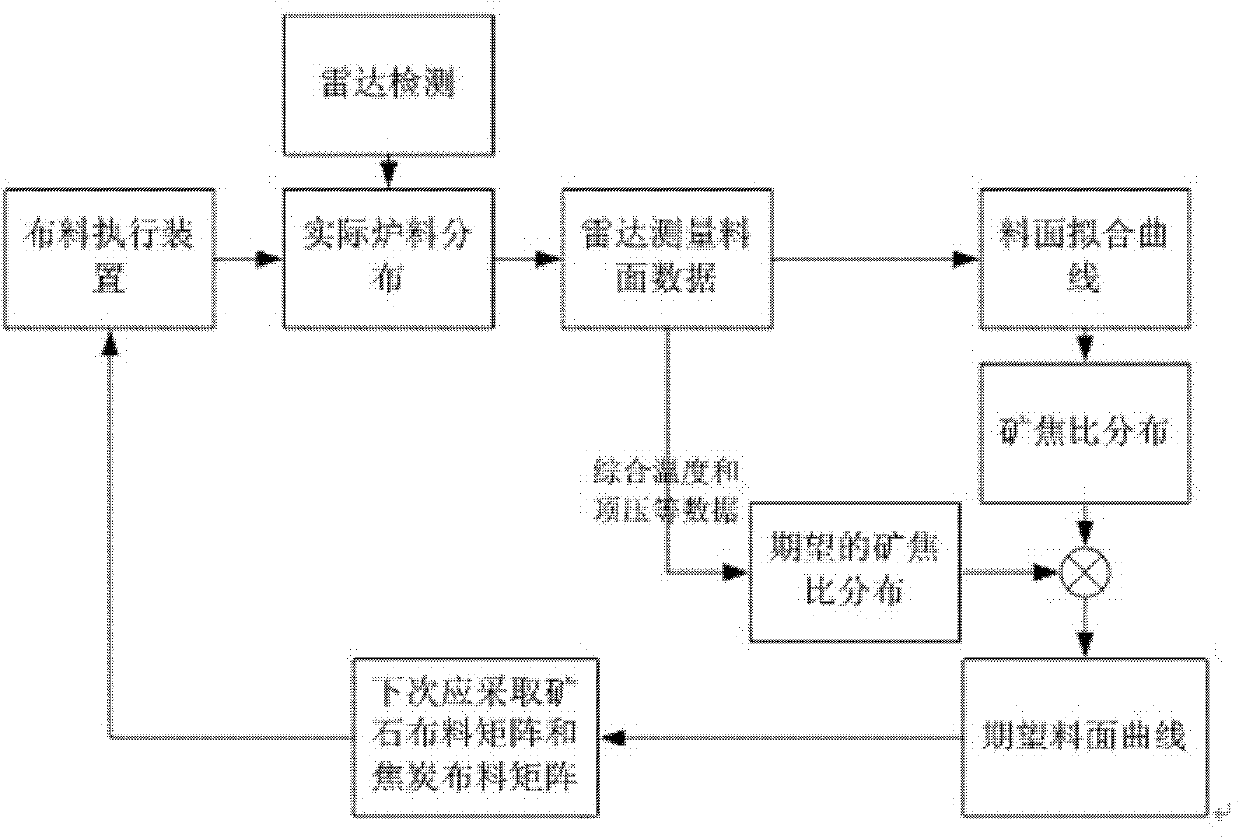

Bell-less blast furnace top distribution closed-loop control method based on multipoint radar data

A radar data, closed-loop control technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as real-time feedback adjustment of distribution matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

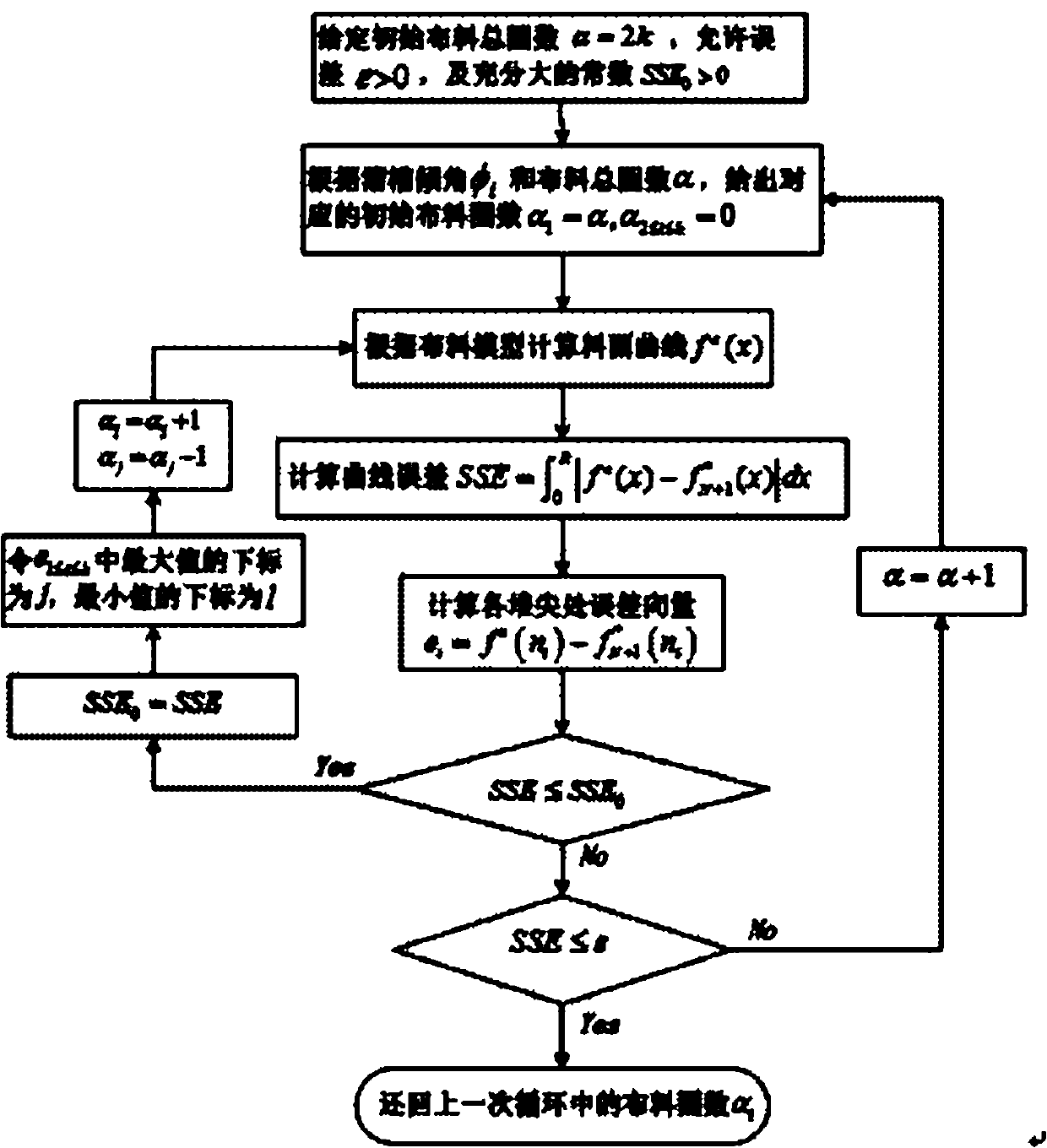

[0033] The following analysis is based on the Baosteel 2500m installed 6-point radar 3 on the blast furnace.

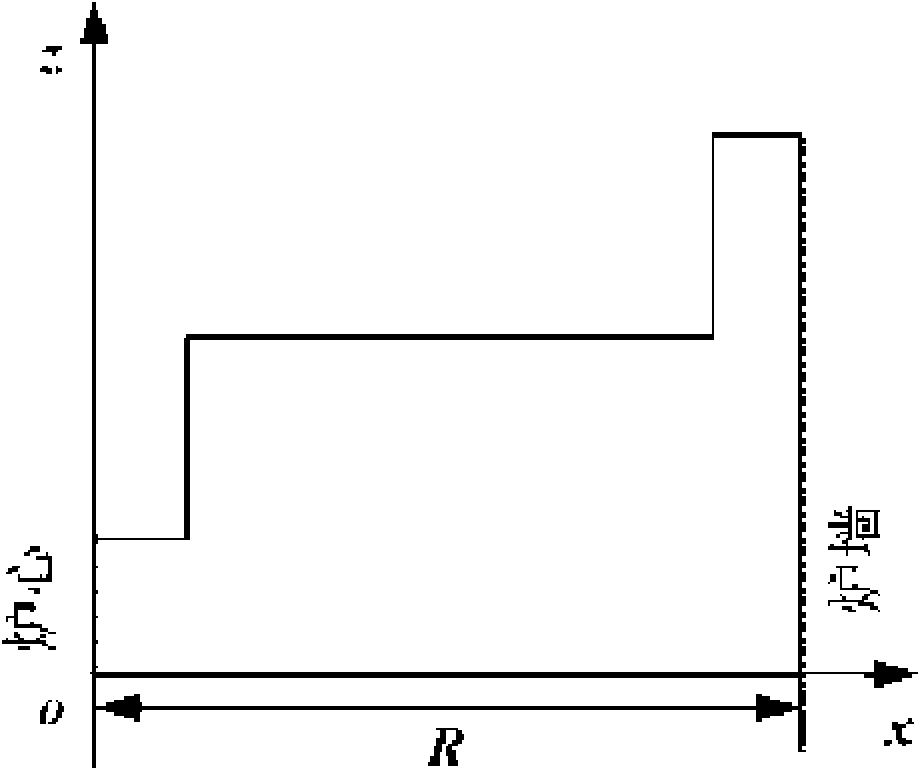

[0034] 1) Material surface shape fitting

[0035] The ore distribution matrix is known, and the ore material surface curve is estimated. According to the cloth model, the ore reference material surface curve can be calculated It is assumed that the reference material surface curve has p stack tips, and the coordinates of the intersection points of the stack tips, stack valleys and curves with the furnace core and the furnace wall are i=1, 2..., 2p+1; set the 6-point radar measurement data as (x i ,y i ), i=1,2,...,6; use 2p+2=rho polynomial to fit the material surface, that is, to set the material surface curve as

[0036] f(x)=a ρ x ρ +a ρ-1 x ρ-1 +...+a 1 x+a 0

[0037] Then, using the weighted least squares method, the ore fitting material surface curve can be obtained In the same way, the coke fitting material surface curve can be obtained as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com