Steel-smelting regulator and preparation thereof

A technology of adjusting agent and bonding agent, which is applied in the field of iron and steel smelting, can solve the problems of dust removal and pollution of the environment, achieve good effect, reduce production cost, and realize the effect of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

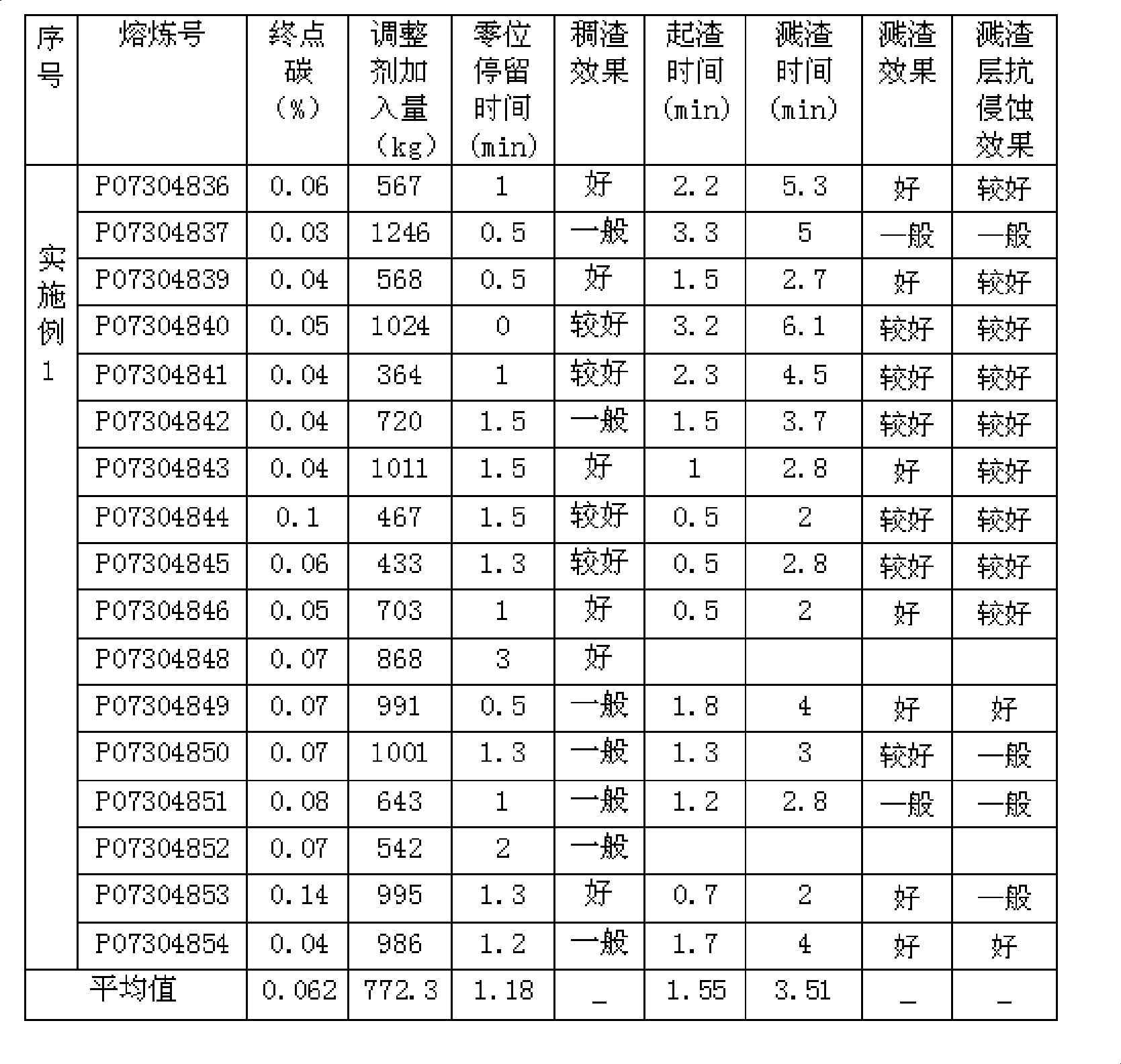

Embodiment 1

[0046] Example 1 Preparation of steelmaking regulator of the present invention

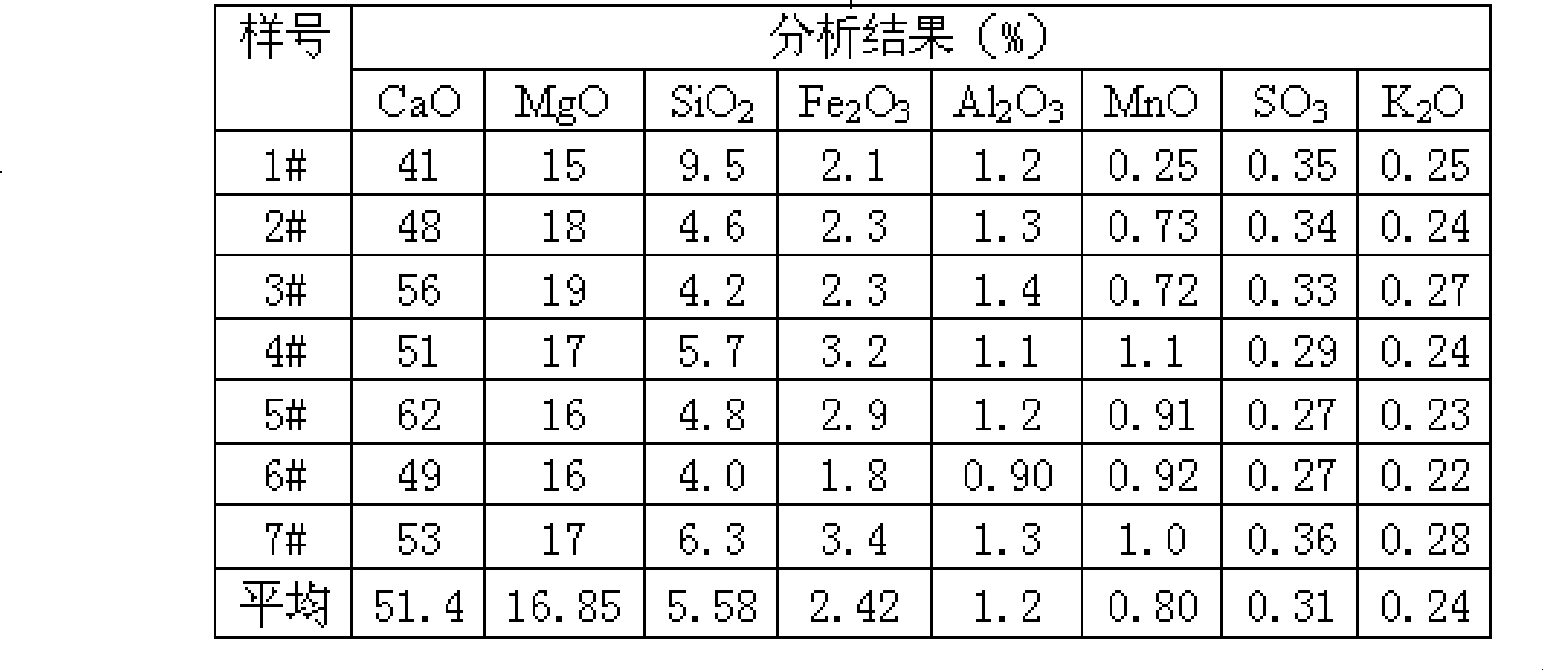

[0047] After weighing 67% by weight of dust ash, 13% by weight of silicon carbide material and 20% by weight of magnesia material, they are sent into the mixing mixer for thorough mixing and stirring, and magnesium chloride is added during the mixing and stirring process. Addition amount is 5% by weight of the total weight (the total weight of dust removal ash, silicon carbide material, and magnesium material), slowly and uniformly add in an appropriate amount of water, mixed and stirred, and then sent to the ball press to make a ball of 30mm~ 50mm oval. Then pile and dry naturally for 48 hours (waterproof and sunscreen during drying) to further improve the product strength. The product is then dried in a vertical drying oven, the drying temperature is 220-250℃, and the drying time is 1h. Baked products have been tested for chemical composition (see Table 3 for chemical composition testing) and crushi...

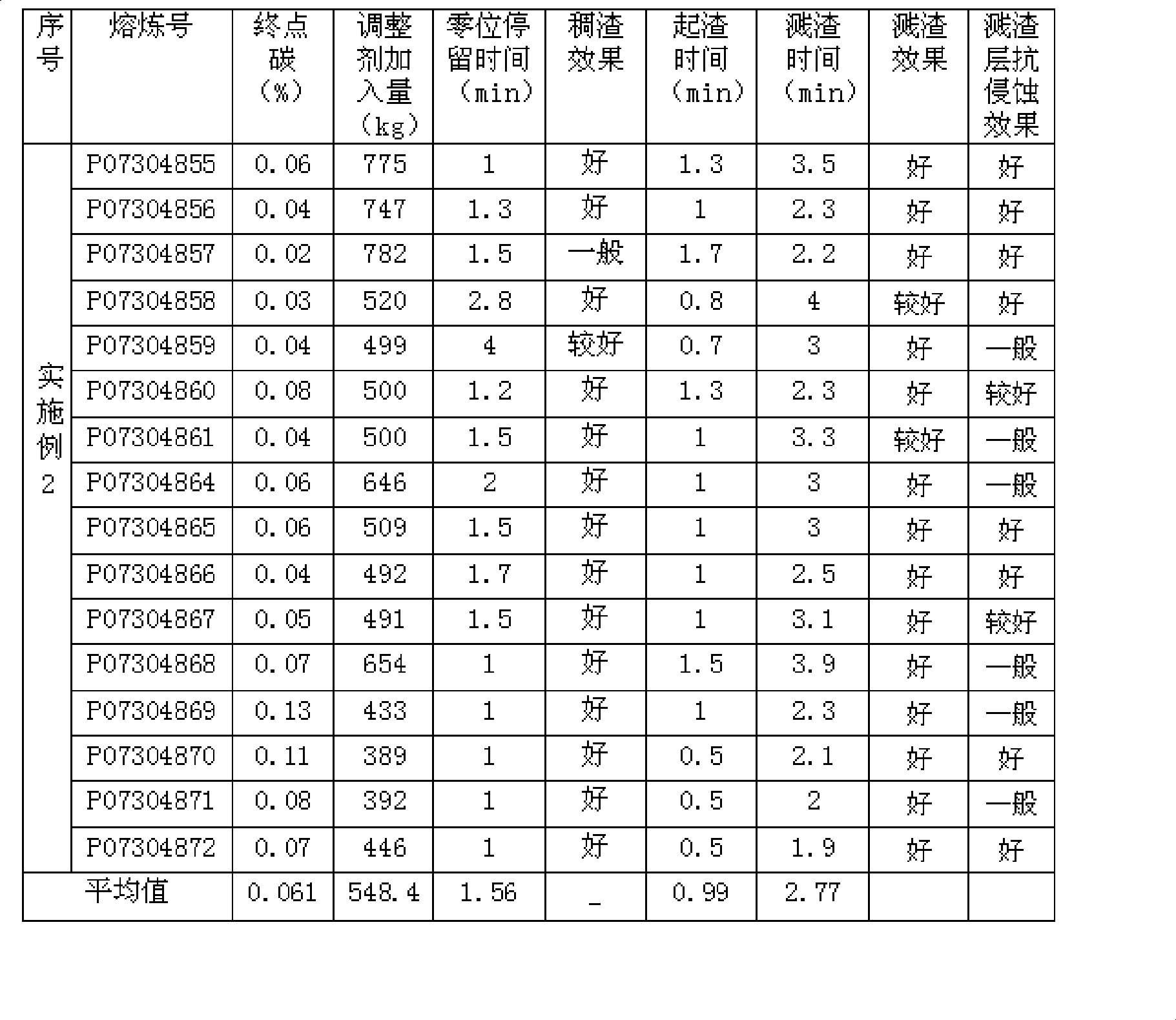

Embodiment 2

[0048] Example 2 Preparation of steelmaking regulator of the present invention

[0049] 73% by weight of dust removal ash, 7% by weight of silicon carbide material and 20% by weight of magnesia material are weighed and sent into the mixing mixer for thorough mixing and stirring, and magnesium chloride binder is added during the mixing and stirring process , The addition amount is 5% by weight of the total weight (the total weight of dust removal ash, silicon carbide materials, and magnesium materials), slowly and uniformly add in and an appropriate amount of water, mixed and stirred, and then sent to the ball press to press into a ball of 30mm-50mm Oval shape. Then pile and dry naturally for 48 hours (waterproof and sunscreen during drying) to further improve the product strength. The product is then dried in a vertical drying oven, the drying temperature is 220-250℃, and the drying time is 1h. The baked products have been tested for chemical composition (see Table 3 for chemical ...

Embodiment 3

[0050]Example 3 Preparation of steelmaking regulator of the present invention

[0051] Weigh 70% by weight of dust removal ash, 12% by weight of silicon carbide material, and 18% by weight of magnesia material, and then send them into the mixing mixer for thorough mixing and stirring, and adding magnesium chloride binder during the mixing and stirring process , The addition amount is 5% by weight of the total weight (the total weight of dust removal ash, silicon carbide materials, and magnesium materials), slowly and uniformly add in and an appropriate amount of water, mixed and stirred, and then sent to the ball press to press into a ball of 30mm-50mm Oval shape. Then pile and dry naturally for 48 hours (waterproof and sunscreen during drying) to further improve the product strength. The product is then dried in a vertical drying oven, the drying temperature is 220-250℃, and the drying time is 1h. The baked products have been tested for chemical composition (see Table 3 for chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com