Method for preparing sigma-phase FeV50

An electroaluminothermic and vanadium oxide technology is applied in the field of metallurgy to achieve the effects of enhancing process control capability, increasing vanadium yield and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

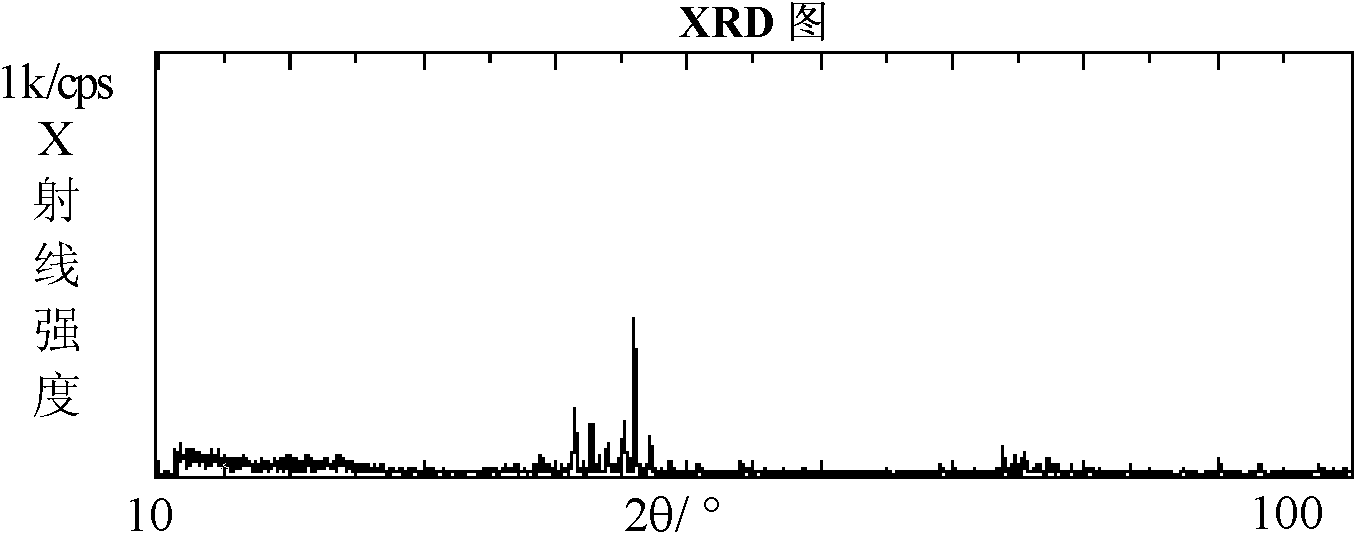

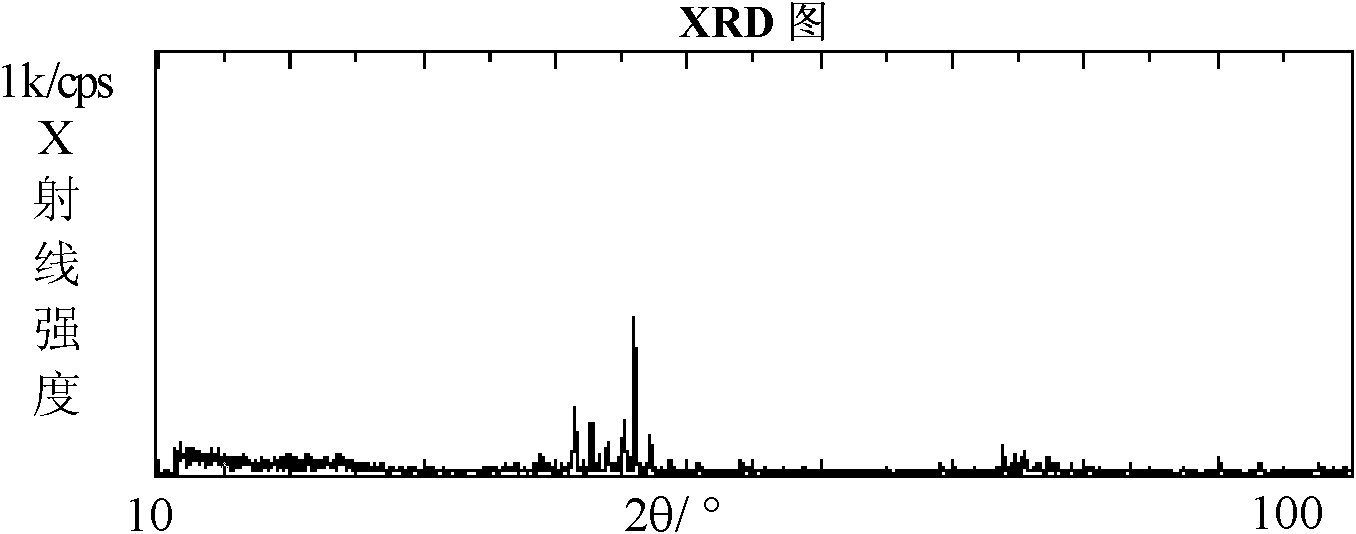

Image

Examples

Embodiment 1

[0023] Example 1 Preparation of σ-phase FeV50 using the method of the present invention

[0024] Raw material: prepare the sheet vanadium (V 2 o 5 )250kg, V 2 o 3 1200kg, with 650kg of aluminum, 770kg of iron filings and 240kg of lime. Mix the material evenly and put it into the furnace. The secondary voltage is 190V to energize the arc. After the furnace material is cleared, the secondary voltage is 135V. After 60 minutes of power on, the residual vanadium in the slag is quickly analyzed to be 0.7%. Remove the poor slag and continue to energize. The voltage was 135V, and the alloy sample was taken to quickly analyze that the Al content was 1.2%. At this time, 50kg of vanadium flakes were added for dealumination. After 5 minutes, the alloy sample was taken again for analysis. The aluminum content was 0.78%. Vanadium 50.6%, vanadium recovery rate 97.3%, all σ phase, easy to break, crushing strength 505MPa.

[0025] The testing method of the crushing strength: take the van...

Embodiment 2

[0026] Example 2 Using the method of the present invention to prepare σ-phase FeV50

[0027] Raw material: prepare the sheet vanadium (V 2 o 5 )250kg, V 2 o 3 800kg, with 480kg of aluminum, 560kg of iron filings, and 100kg of lime. Mix the material evenly and put it into the furnace. The secondary voltage is 190V to energize the arc. After the furnace material is cleared, the secondary voltage is 135V. After 35 minutes of power on, the residual vanadium in the slag is quickly analyzed to be 0.9%. Remove the poor slag and continue to energize. The voltage was 135V, and the alloy sample was taken to quickly analyze that the Al content was 1.6%. At this time, 30kg of vanadium flakes were added for dealumination. After 5 minutes, the alloy sample was taken again for analysis. The aluminum content was 0.46%. Vanadium 50.8%, vanadium recovery rate 96.9%, all σ phase, easy to break, crushing strength 390MPa.

Embodiment 3

[0028] Example 3 Using the method of the present invention to prepare σ-phase FeV50

[0029] Raw material: prepare the sheet vanadium (V 2 o 5 )300kg, V 2 o 3 800kg, with 520kg of aluminum, 580kg of iron filings, and 120kg of lime. Mix the material evenly and put it into the furnace. The secondary voltage is 190V to energize the arc. After the furnace material is cleared, the secondary voltage is 135V. After 30 minutes of power on, the residual vanadium in the slag is quickly analyzed to be 0.8%. Remove the poor slag and continue to energize. The voltage was 135V, and the alloy sample was taken to quickly analyze that the Al content was 1.1%. At this time, 50kg of vanadium flakes were added for dealumination. After 5 minutes, the alloy sample was taken again for analysis. The aluminum content was 0.66%. Vanadium 50.5%, vanadium recovery rate 97.0%, all σ phase, easy to break, crushing strength 499MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crush strength | aaaaa | aaaaa |

| Crush strength | aaaaa | aaaaa |

| Crush strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com