Control method of as-cast condition heavy section ferrite-based nodular iron casting graphite nodule and matrix structure

A control method, thick section technology, applied in

The present invention relates to field, can solve problems such as elongation reduction, solidification time is long, reduces casting performance, reaches the effect of excellent low-temperature impact performance, easy to grasp and operate, and reduces production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

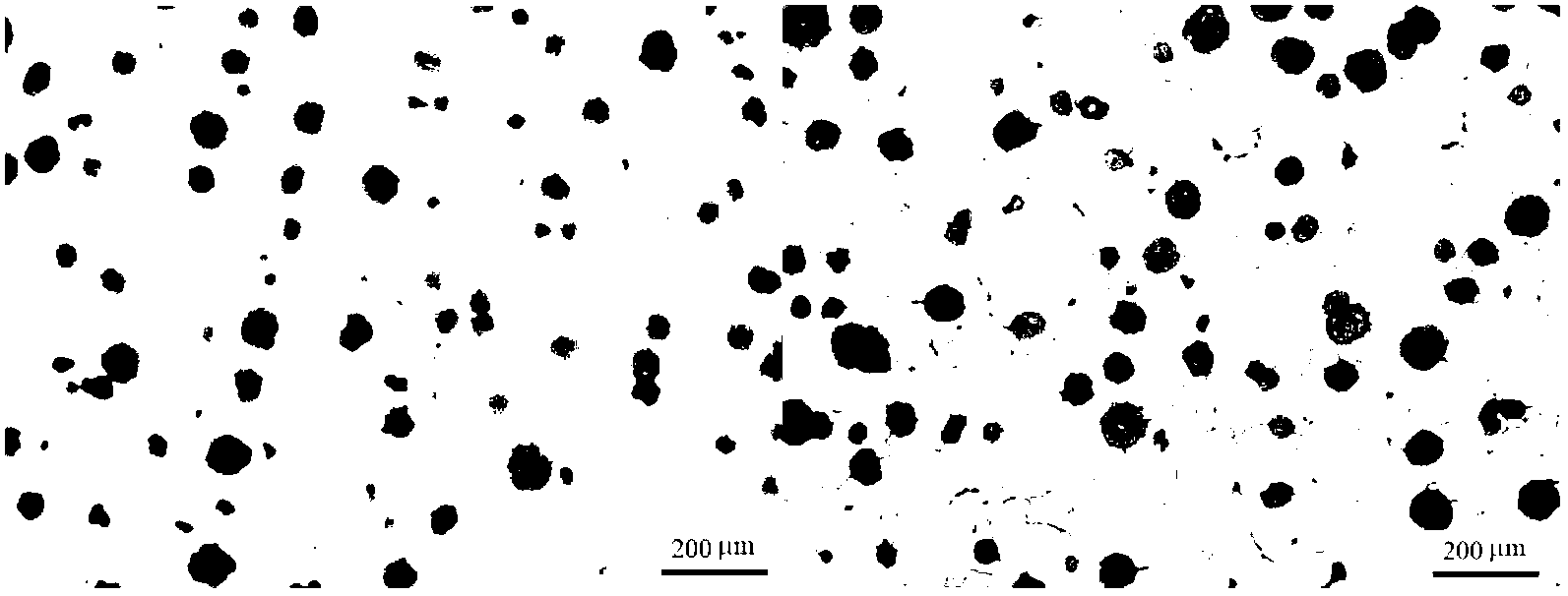

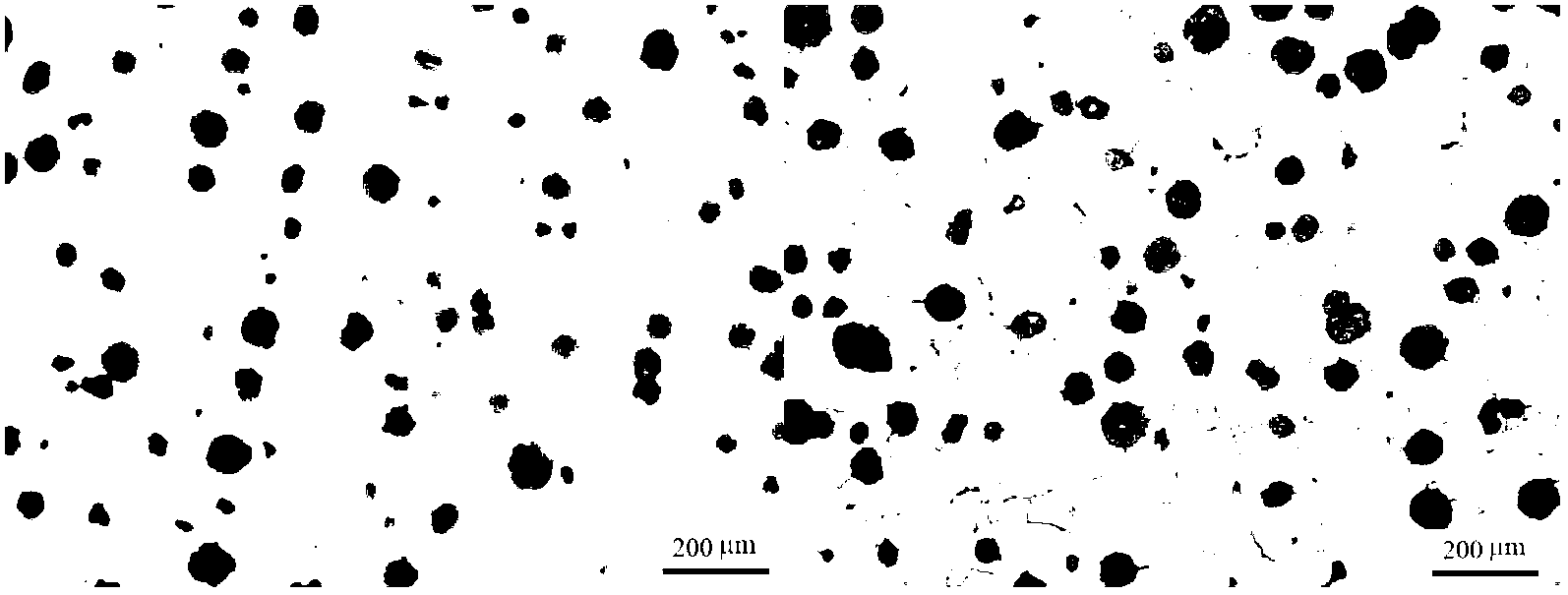

Embodiment 1

[0021] The casting size of this embodiment is 200×200×200mm 3 According to the shape of the bag pit of the spheroidizing treatment bag, a pressed iron plate is made, and the size of the plate just fills the bag pit; pig iron, recycled material, scrap steel and ferrosilicon are selected as ingredients, and the smelted molten iron is 1523°C for the spheroidizing treatment bag Hot ladle, hot ladle time is 4min; add Elkem 5800 nodulizer with 1.05% weight of molten iron and 4% Elkem high-calcium barium inoculant in turn in the ladle pit after ladle, and sprinkle the weight of molten iron on the inoculant For 0.2% iron filings, after compaction, put a pressed iron plate on the top of the bag pit, then add pig iron, the total weight of pig iron and pressed iron plate is 4% of the weight of the processed molten iron, and finally add 30ppm of Sb; control the mass fraction of the original molten iron For: C: 3.75-3.85%, Si: 1.10-1.40%, Mn<0.15%, P<0.050%, S<0.02%, the temperature of mol...

Embodiment 2

[0025] The casting size of this embodiment is 200×200×200mm 3 According to the shape of the pit of the spheroidizing treatment bag, a pressed iron plate is made. The size of the flat plate is just enough to fill the pit. Pig iron, recycled material, scrap steel and ferrosilicon are selected as ingredients, and the smelted molten iron is 1510°C for the spheroidizing treatment bag. Hot ladle, hot ladle time is 4min; add Elkem 5800 nodulizer with 1.05% weight of molten iron and 4% Elkem high-calcium barium inoculant in turn in the ladle pit after ladle, and sprinkle the weight of molten iron on the inoculant 0.2% of the iron filings, after compaction, put the pressed iron plate on the top of the bag pit, then add pig iron, the total weight of the pig iron and the pressed iron plate is 4% of the weight of the processed molten iron, and finally add 50ppm of Sb;; control the original molten iron Mass fraction: C: 3.75-3.85%, Si: 1.10-1.40%, Mn<0.15%, P<0.050%, S<0.02%, the temperatu...

Embodiment 3

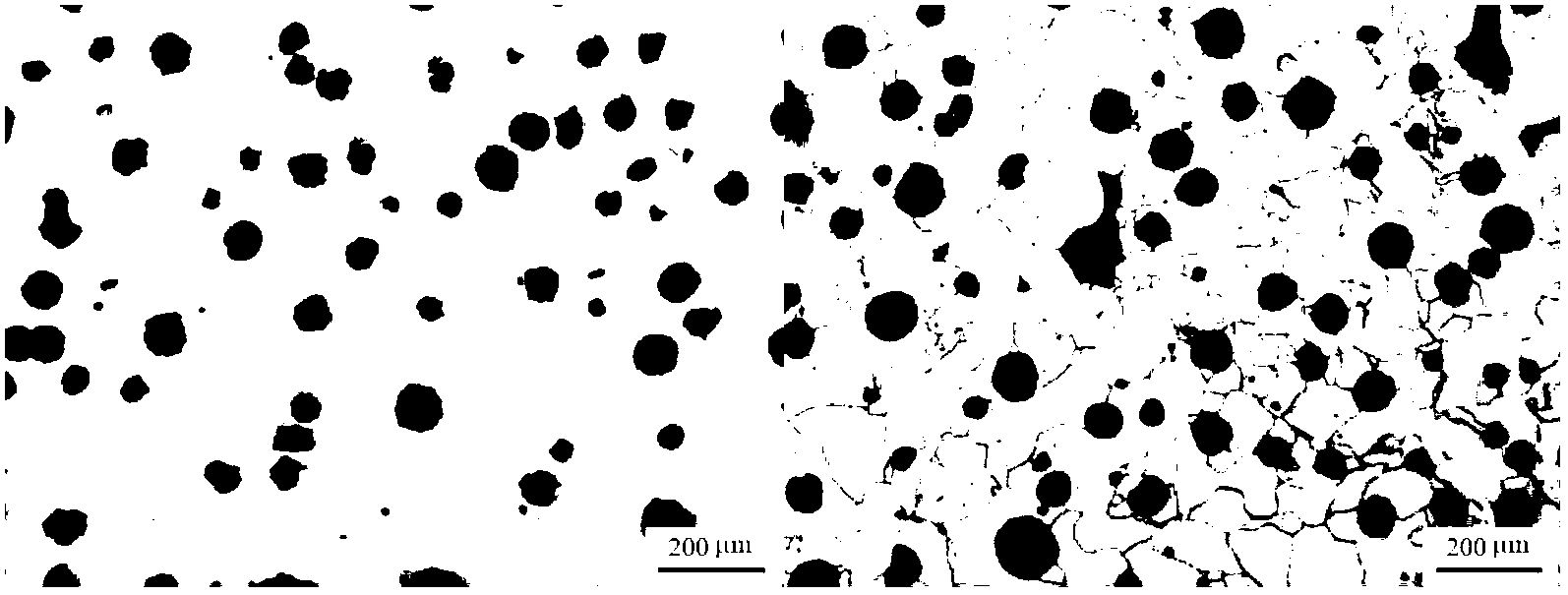

[0029] The casting size of this embodiment is 250×250×250mm 3 According to the shape of the pit of the spheroidizing treatment bag, a pressed iron plate is made. The size of the flat plate is just enough to fill the bag pit. Pig iron, recycled material, scrap steel and ferrosilicon are selected as ingredients, and the smelted molten iron is spheroidized at 1513°C. Hot ladle, hot ladle time is 4min; add Elkem 5800 nodulizer with 1.05% weight of molten iron and 4% Elkem high-calcium barium inoculant in turn in the ladle pit after ladle, and sprinkle the weight of molten iron on the inoculant 0.2% of the iron filings, after compaction, put the pressed iron plate on the top of the bag pit, then add pig iron, the total weight of the pig iron and the pressed iron plate is 5% of the weight of the processed molten iron, and finally add 50ppm of Sb; control the quality of the original molten iron Score: C: 3.75-3.85%, Si: 1.10-1.40%, Mn<0.15%, P<0.050%, S<0.02%, the temperature of molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength σ0.2 | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com