Furnace burden optimization method for iron-making system

An optimization method and charge technology, applied in the direction of furnaces, blast furnaces, furnace types, etc., can solve the problems of lack of overall overall ironmaking optimization methods, limitations, high smelting costs, etc., and achieve the effects of excellent products, high production output, and cost reduction

Active Publication Date: 2015-05-06

NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF3 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It solves the problem that the existing optimization method of ironmaking charge is only limited to a certain process of ore blending, sintering and ironmaking, lacks an overall overall planning ironmaking optimization method, and has high smelting costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0023] 1. Detection and analysis of metallurgical performance of sinter

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

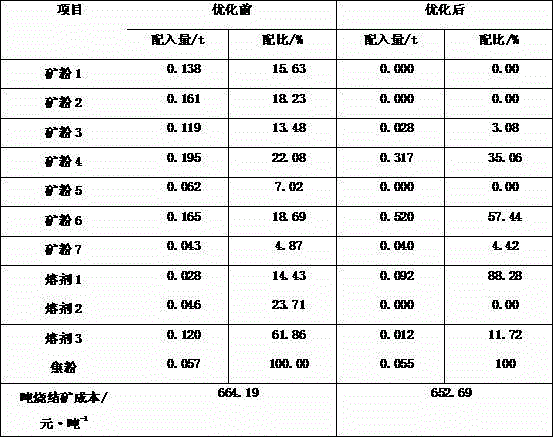

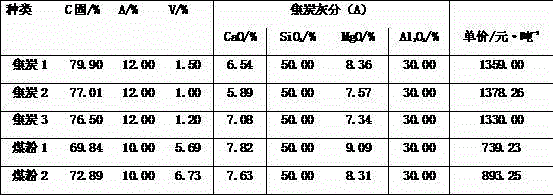

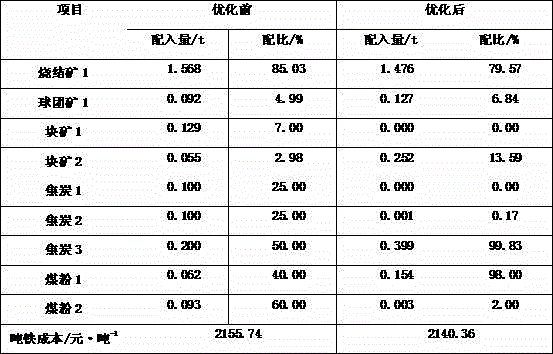

The invention relates to a furnace burden optimization method, and particularly relates to a comprehensive proportioning optimization method for sintered ores and blast furnace burdens. The comprehensive proportioning optimization method is a six-in-one furnace burden optimization method for an iron-making system, comprising sintered ore metallurgical performance detection and analysis, sintering process proportioning optimization, sintered ore ingredient predication and analysis, blast furnace burden structure optimization, blast furnace proportioning calculation, iron-making system furnace burden structure multi-target optimization; the optimal proportioning ratios and the optimal ingredients of the various furnace burdens of sintering proportioning and blast furnace proportioning are determined; the problems of limit to a certain procedure of ore blending, sintering and iron-making, high cost and instable quality of the existing iron-making furnace burden optimization method are solved. The furnace burden optimization method disclosed by the invention overall plans the whole iron-making process, highly scientifically analyses, plans and calculates from the whole system, furthest reduces the cost, and finds a furnace burden optimization scheme for an iron-making system, which is low in pig iron production cost, excellent in products and high in yield.

Description

technical field [0001] The invention relates to a furnace charge optimization method, in particular to a furnace charge optimization method for an ironmaking system. Background technique [0002] The ironmaking production process is a system engineering closely related to each process. At present, the cost of ironmaking in domestic iron and steel enterprises is very different. The cost per ton of iron varies from tens to hundreds of yuan. For an ordinary enterprise with an annual output of 5 million tons, the annual cost can vary from 100 million to several billion. The reason is that the difference in ingredient structure is a crucial factor in determining the cost. At present, there are many kinds of raw materials for ironmaking, complex components, and large price gaps. However, the existing methods for optimizing the structure of ironmaking furnace materials are limited to a certain process such as ore blending, sintering, and ironmaking, and lack overall system conside...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21B5/00G06F19/00

Inventor 陈伟王宝祥陈颖朱祎姮赵骥张慧娟

Owner NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com