Treatment method for jamesonite and equipment thereof

A technology of brittle sulfur-lead-antimony ore and its treatment method, which is applied in the field of non-ferrous metal smelting methods and devices, can solve problems such as resource waste, environmental pollution, and complicated processes, and achieve the effects of reducing power consumption and solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment is an example of the device used in the processing method of the brittle pyrosterite of the present invention.

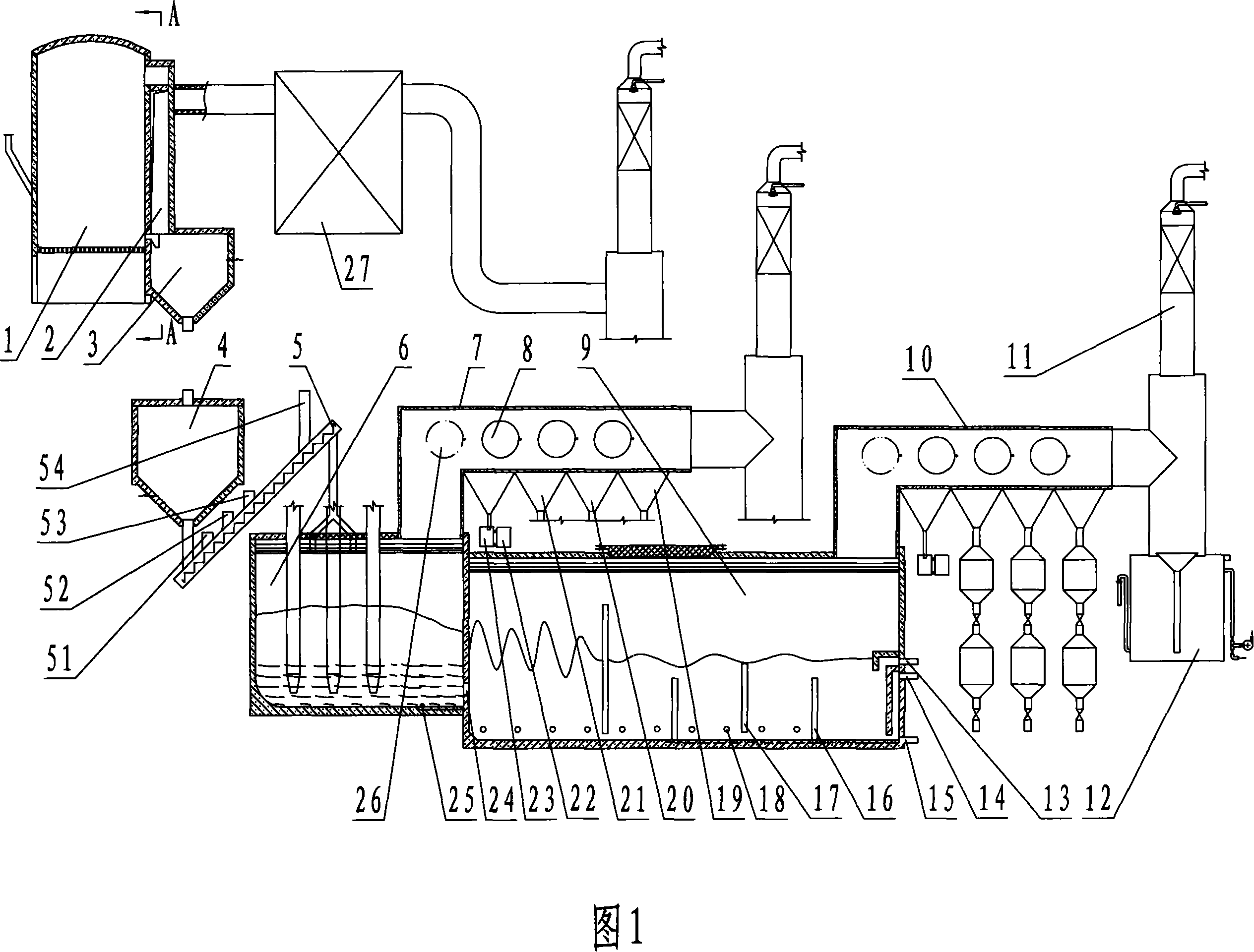

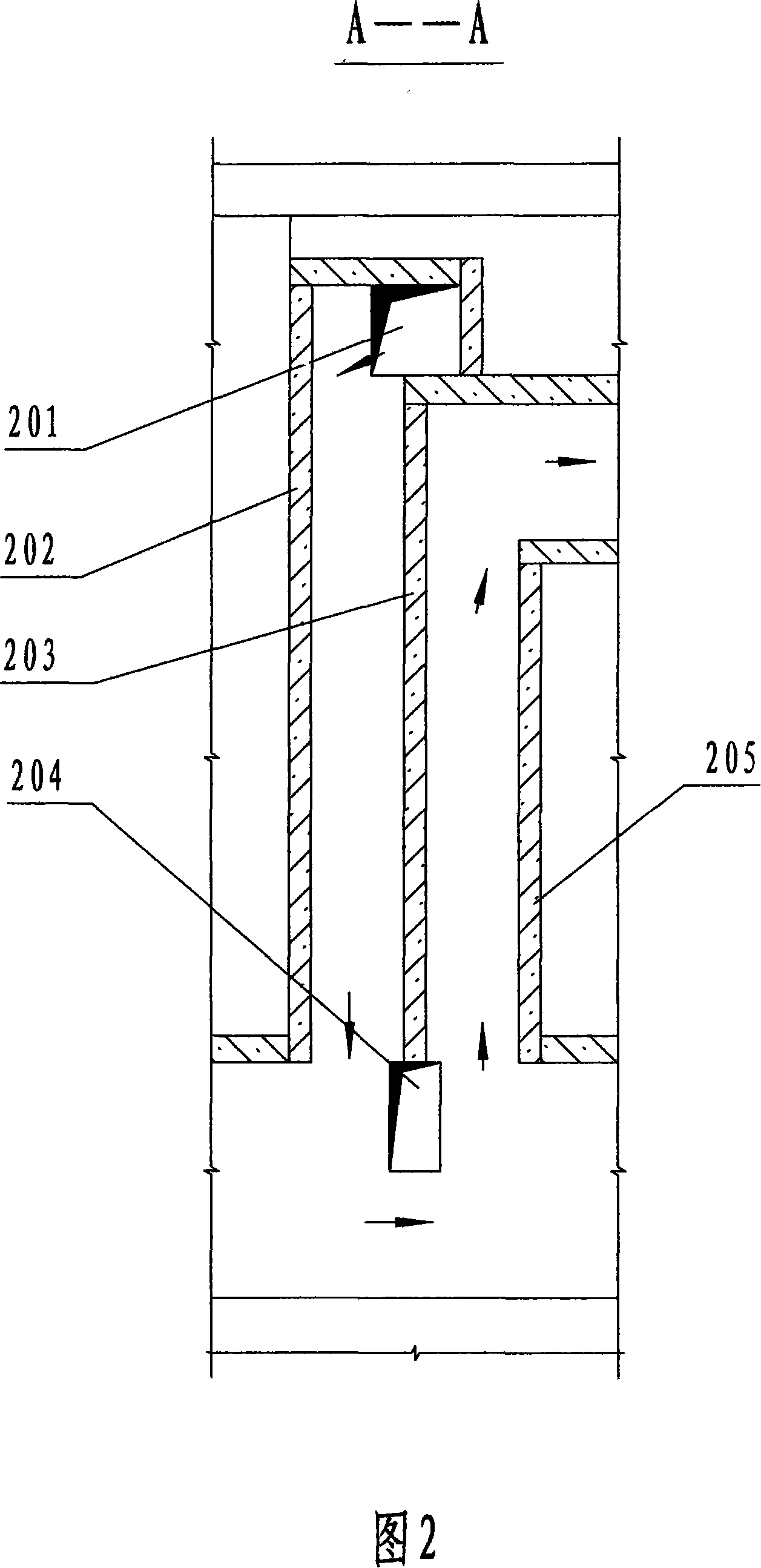

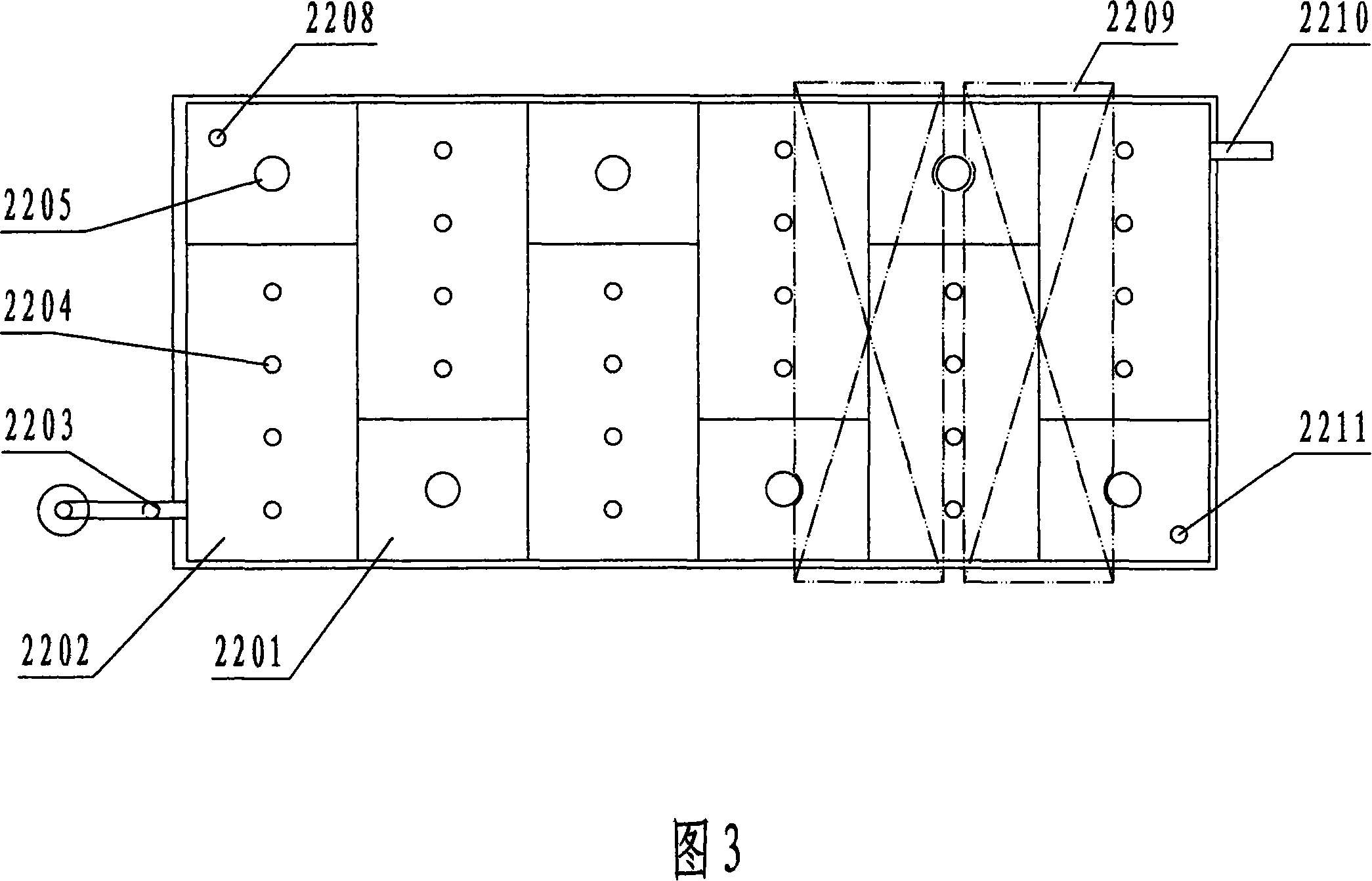

[0051] With reference to Fig. 1, the device used in the processing method of the brittle sulfur-lead-antimony ore of the present invention is mainly composed of fluidized fluidized furnace 1, "U" shape flue 2, upper calcined sand storage bin 3, lower calcined sand storage bin 4, and screw feeding Machine 5, electric furnace 6, horizontal flue 7, constant temperature condensing drum 8, continuous fuming furnace 9, fuming furnace horizontal flue 10, flue gas leaching tower 11, leaching soot settlement tank 12, siphon slag discharge port 13 , siphon lead discharge port 14, furnace cleaning port 15, overflow partition 16, siphon partition 17, blower port 18, sulfur product receiving bucket 19, arsenic product receiving bucket 20, antimony product receiving bucket 21, multi-stage The countercurrent melting tank 22, the melting tank 23, the electric...

Embodiment 2

[0061] This embodiment is the processing method steps and process conditions of the brittle pyrostibite described in the present invention.

[0062] The main components of brittle pyrostibite: Pb27.20, Sb18.98, Zn5.59, S23.00, Fe13.92, As1.22, Sn1.07, Cu0.2~0.4, In0.034, Cd0.055 , Bi0.16, Ag0.125, C1.84, CaO0.65, SiO 2 2.60, Al 2 o 3 0.27. The purpose of the fluidized furnace roasting in this embodiment is to desulfurize the brittle pyridoxite, and does not require the removal of arsenic and antimony. Antimony is required to generate antimony tetroxide (Sb 2 o 4 ), the controlled roasting conditions are: boiling layer temperature 700-750°C, excess air coefficient 1.2-1.35 by air blast, desulfurization rate 95%.

[0063] The flue gas from the fluidized fluidized furnace enters the upper calcine storage bin 3 through the "U"-shaped descending flue, and then rises to the bottom line of the flue gas outlet along the "U"-shaped ascending flue through the leaching of the calci...

Embodiment 3

[0068] This embodiment is an application example of using the flue reduction tank of the present invention. As a solution to SO 2 and a small amount of As 2 o 3 Environmental pollution problems, while recovering a small amount of volatilized PbO and a small amount of Sb that did not enter the calcine 2 o 3 , using flue reduction tank to reduce SO 2 reduced to elemental sulfur, the As 2 o 3 reduced to metallic arsenic or realgar (A 2 S 2 ), reducing lead antimony oxide to metallic lead and metallic antimony.

[0069] Referring to Figure 6, the flue reduction tank is composed of a flue gas pipeline 2701, a sealed feed system 2702, a first reduction tank 2703, a porcelain ring 2704, a sieve plate 2705, a reduction residue sealed conveying screw 2706, and a sealed slag discharge barrel 2707 , Reduction liquid lead receiving tank 2708, high temperature condensation drum 2709, condensed liquid lead receiving tank 2710, metal antimony sealed discharge tank 2711, second secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com