380L vehicle beam black steel and production method thereof

An automobile beam and production method technology, applied in the field of steelmaking, can solve the problems of uneven thickness of oxide layer, unstable structure of surface oxide layer, etc., and achieve the effects of good adhesion, excellent mechanical properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

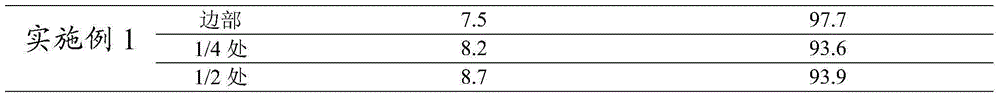

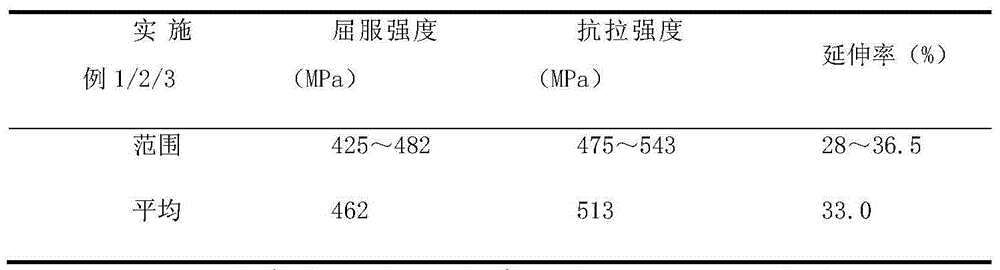

Embodiment 1

[0018] A 380L black skin steel for automobile beams, characterized in that, according to the mass percentage, it is composed of the following components: C: 0.07%; Si: 0.06%; Mn: 0.90%; P: 0.010%; S: 0.006%; Als: 0.03%; Nb: 0.030%; Cr: 0.10%; Ti: 0.010%;

[0019] The production method of the 380L black skin steel for automobile frame with the above composition comprises the steps of: hot metal desulfurization pretreatment→converter smelting→RH refining→continuous casting→hot continuous rolling;

[0020] Among them, in hot continuous rolling, the casting billet is heated at 1200°C and held for 2 hours. After heating, it enters rough rolling. During rough rolling, high pressure water descaling requires a pressure of 15MPa; when entering rough rolling, R1 two rolls are reversible. The roughing mill is put into 3 passes, the R2 four-high reversible roughing mill is put into 2 passes, and the rolling start temperature is controlled at 1190°C±20°C when passing through the R1 two-rol...

Embodiment 2

[0034] The difference from Implementation 1 is that: a 380L black skin steel for automobile beams is composed of the following components according to the mass percentage: C: 0.06%; Si: 0.02%; Mn: 0.81%; P: 0.008%; S: 0.002%; Als: 0.02%; Nb: 0.020%; Cr: 0.08%; Ti: 0.0050%; the balance is Fe

[0035] The production method of the above-mentioned 380L black skin steel for automobile frame comprises the steps of: hot metal desulfurization pretreatment→converter smelting→RH refining→continuous casting→hot continuous rolling;

[0036] Among them, in hot continuous rolling, the casting billet is heated at 1270°C and held for 3 hours. After heating, it enters rough rolling. During rough rolling, high-pressure water descaling requires a pressure of 20MPa; when entering rough rolling, R1 two-rollers are reversible. The roughing mill is put into 3 passes, the R2 four-high reversible roughing mill is put into 2 passes, and the rolling start temperature is controlled at 1190°C±20°C when pa...

Embodiment 3

[0040] The difference from Example 1 is that a 380L black skin steel for automobile frame is composed of the following components according to the mass percentage: C: 0.08%; Si: 0.08%; Mn: 0.93%; P: 0.012% ; S: 0.007%; Als: 0.04%; Nb: 0.033%; Cr: 0.11%; Ti: 0.020%;

[0041] The production method of the 380L black skin steel for automobile frame with the above composition comprises the steps of: hot metal desulfurization pretreatment→converter smelting→RH refining→continuous casting→hot continuous rolling;

[0042] Among them, in hot continuous rolling, the casting billet is heated at 1200°C and held for 5 hours. After heating, it enters rough rolling. Three roll reversible roughing mills are used for 3 passes, R2 four-high reversible roughing mills are put into two passes, and the rolling start temperature is controlled at 1190°C±20°C when passing through R1 two-roller reversible roughing mills;

[0043] After the rough rolling, it enters the fine rolling. The temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com