Patents

Literature

44results about How to "Good surface adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

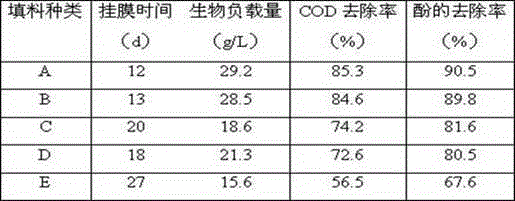

Preparation method of suspended packing bioreactor and application thereof

ActiveCN104609567AHigh speedImprove efficiencyWater contaminantsSustainable biological treatmentSlagUltraviolet

The invention provides a preparation method of a suspended packing bioreactor. The preparation method comprises the following steps: (1) uniformly mixing 0.2-0.6 part by weight of magnetic powder, 7-10 parts by weight of recycled rubber powder, 3-12 parts by weight of zeolite, 2-8 parts by weight of maleic anhydride, 0.2-0.8 part by weight of dicumyl peroxide, 0.5-2 parts by weight of chitin, 3-5 parts by weight of powdered coke and 1-2 parts by weight of slag powder, adding 70-75 parts by weight of high density polyethylene, and stirring at high speed; (2) adding the above mixed materials into a screw pelletizer and pelleting; (3) putting the pelleted particles into a screw extruder and carrying out extrusion molding, carrying out vacuum setting, cooling, carrying out mechanical holing, and carrying out cutting forming; and (4) finally irradiating the packing bioreactor by short wave ultraviolet. According to the invention, hydrophily of the suspended packing bioreactor is greatly enhanced, surface adsorbing capacity is increased, biofilm adsorption strength is raised, biofilm culturing period is shortened, and the biofilm is not easy to fall off. The suspended packing bioreactor is suitable for processing low concentration organic wastewater and phenolic wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

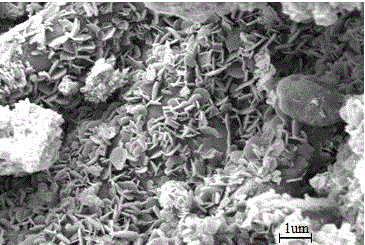

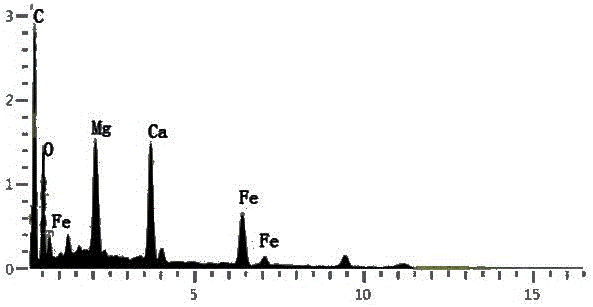

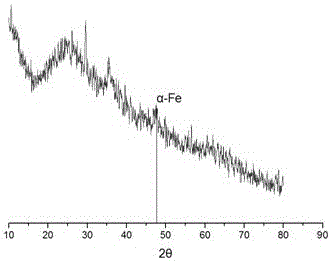

Method for preparing nanometer iron-loaded amine-modified bio-char and application thereof

InactiveCN106179208AWide range of usesEasy wayOther chemical processesWater contaminantsOrganic chemistryAdsorption effect

The invention relates to the preparation and application of nano-iron-loaded amino-modified biological carbon. In this method, the biochar treated with deashing is used as the substrate, and its surface characteristics and reactivity are improved through amino modification; the nano-iron produced by the reaction is fully and uniformly loaded on the amino-modified bio-char, and the obtained nano-iron Amino-loaded modified biochar has stable properties, is not easy to agglomerate, and has a greatly increased adsorption capacity. Applying it to the degradation of heavy metal Cd can significantly reduce the problem of activity reduction caused by the agglomeration effect of nano-iron itself. The adsorption effect of biochar and the reduction effect of nano-iron are exerted, and the treatment effect is significantly enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Heavy-release force release film having surface microviscosity and preparation method thereof

InactiveUS20150267085A1Good surface adhesionSimple processFilm/foil adhesivesPretreated surfacesForeign matterFirming agent

Disclosed is a heavy-release force release film having surface microviscosity and a preparation method thereof A release layer of the release film comprises: by mass, 10 to 25 parts of vinyl silicone oil, 0.5 to 5 parts of a cross-linking agent, 15 to 40 parts of silicon resin, 25 to 60 parts of a pressure-sensitive adhesive, 1 to 6 parts of a curing agent, and 30 to 60 parts of a diluent. The preparation method comprises: removing water, static electricity, dust and foreign matters on a surface of a substrate; uniformly stirring vinyl silicone oil, the cross-linking agent, the pressure-sensitive adhesive, silicon resin and the diluent according to the above mass part ratio; adding the curing agent into the mixture and stirring; coating the release agent on a processed surface of the substrate, drying and carrying out rolling-up.

Owner:SHENZHEN MOMA TECH CO LTD

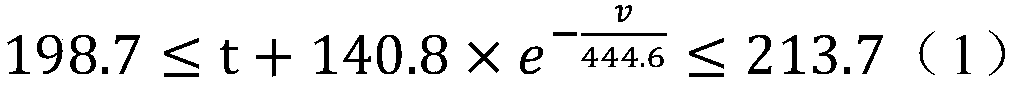

Preparation method of low-temperature high-magnetic induction grain-oriented silicon steel

ActiveCN109136503AHeating fastRapid heating technology is to increase the temperature rise of decarburization annealingAverage sizeSteel belt

The invention relates to the technical field of metallurgy, in particular to a preparation method of low-temperature high-magnetic induction grain-oriented silicon steel. The method includes the steps: smelting; casting blank heating; hot rolling; normalizing; cold rolling; decarburizing annealing; nitriding annealing; coating of high-temperature annealing separating agents; high-temperature annealing; stretching, leveling, insulating layer coating and annealing. The decarburizing annealing process comprises a heating stage and a soaking stage, the heating speed nu of a steel belt is 150DEGC / s-1500 DEG C / s, the temperature rises to 700 DEG C to the temperature of the soaking stage at the heating stage, and the temperature of the soaking stage is 825-845 DEG C. According to the method, by the aid of a rapid heating technique in the decarburizing annealing process, decarburizing annealing time is calculated, the average size and a size fluctuation coefficient of a primary crystal particle after nitriding treatment are defined according to the heating speed, the size of a primary crystal of the low-temperature high-magnetic induction grain-oriented silicon steel is controlled, and uniformity is improved, so that the magnetic performance of the silicon steel is improved.

Owner:武汉钢铁有限公司

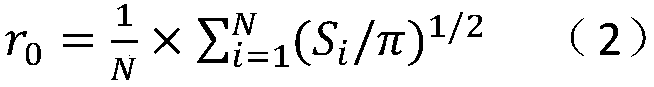

5G high-frequency circuit board solder mask pretreatment method

InactiveCN110856370AAvoid ink bubble phenomenonPrevent oxidationNon-metallic protective coating applicationThermodynamicsSolder mask

The invention discloses a 5G high-frequency circuit board solder mask pretreatment method, which specifically comprises the following step: S1, a circuit board substrate is pretreated, specifically, the substrate is placed on a board grinding machine to be subjected to board grinding treatment, and the surface of the substrate is cleaned twice with pure water after board grinding treatment of thesubstrate. The invention relates to the technical field of high-frequency circuit board solder mask pretreatment. According to the 5G high-frequency circuit board solder mask pretreatment method, thesubstrate is placed on the board grinding machine to be subjected to board grinding treatment, the surface of the substrate is cleaned twice with pure water after board grinding treatment of the substrate, impurities on the surface of the substrate are washed away, and the circuit board substrate is dried by strong wind, wherein the grinding marks are controlled to be 10-15mm, the linear speed ofa brush plate is 10.8m / s, and a brush roller adopts a large dragging shaft. The contact surface is increased, the ink bubble phenomenon of the circuit board substrate in the ink jet printing process can be avoided, the surface oxidation of the circuit board substrate before solder resisting can be avoided, and the pretreatment effect is good.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

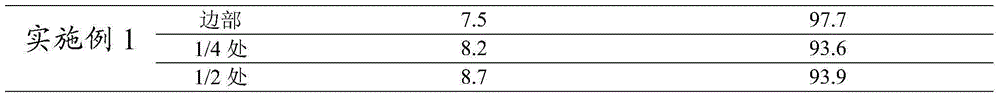

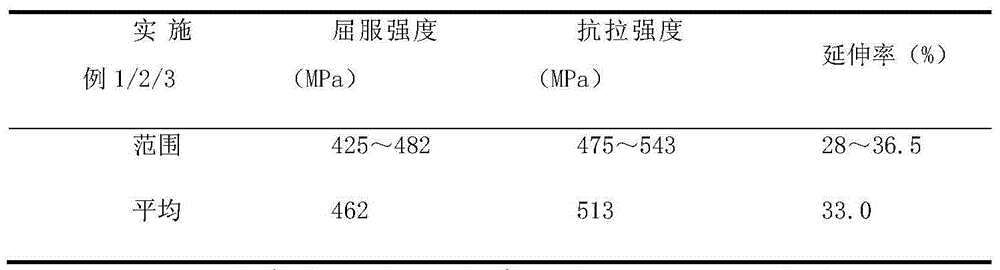

380L vehicle beam black steel and production method thereof

The present invention belongs to the field of steelmaking, and particularly relates to a 380L vehicle beam black steel and a production method thereof, wherein the 380L vehicle beam black steel comprises, by mass, 0.06-0.08% of C, 0.02-0.08% of Si, 0.81-0.93% of Mn, 0.008-0.012% of P, 0.002-0.007% of S, 0.02-0.04% of Als, 0.020-0.033% of Nb, 0.08-0.11% of Cr, 0.0050-0.020% of Ti, and the balance of Fe. The produced 380L vehicle beam hot-rolling black surface steel of the present invention has characteristics of stable chemical component, pure steel, excellent mechanical property, excellent stamping molding performance, and excellent corrosion resistance.

Owner:BENGANG STEEL PLATES

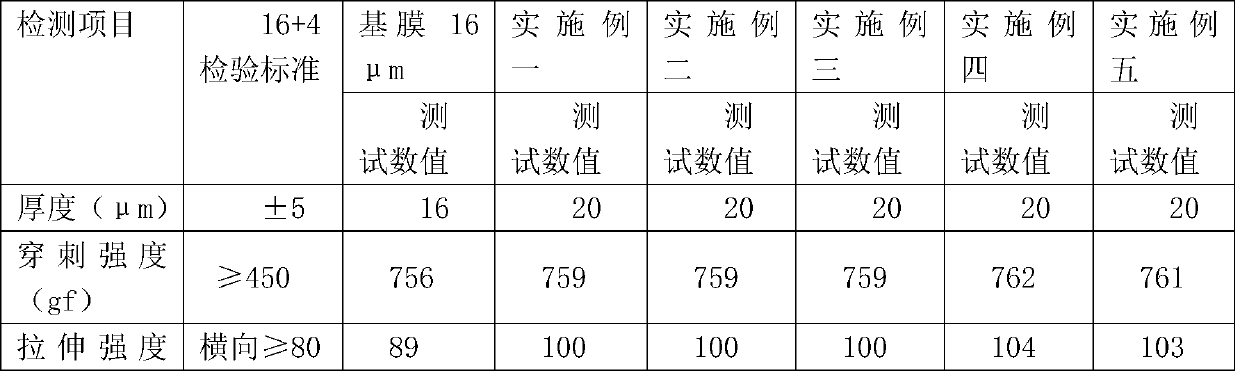

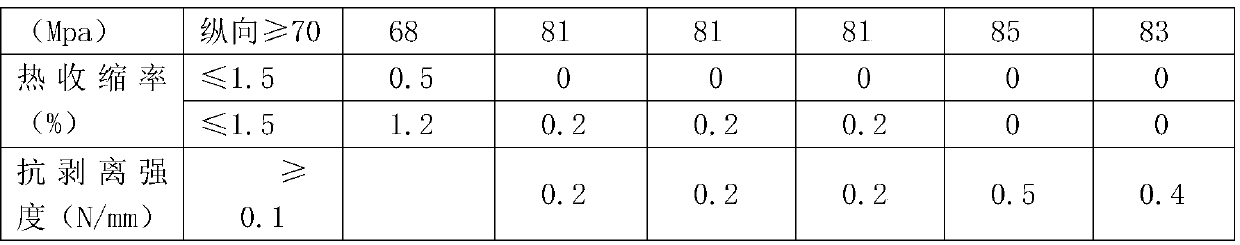

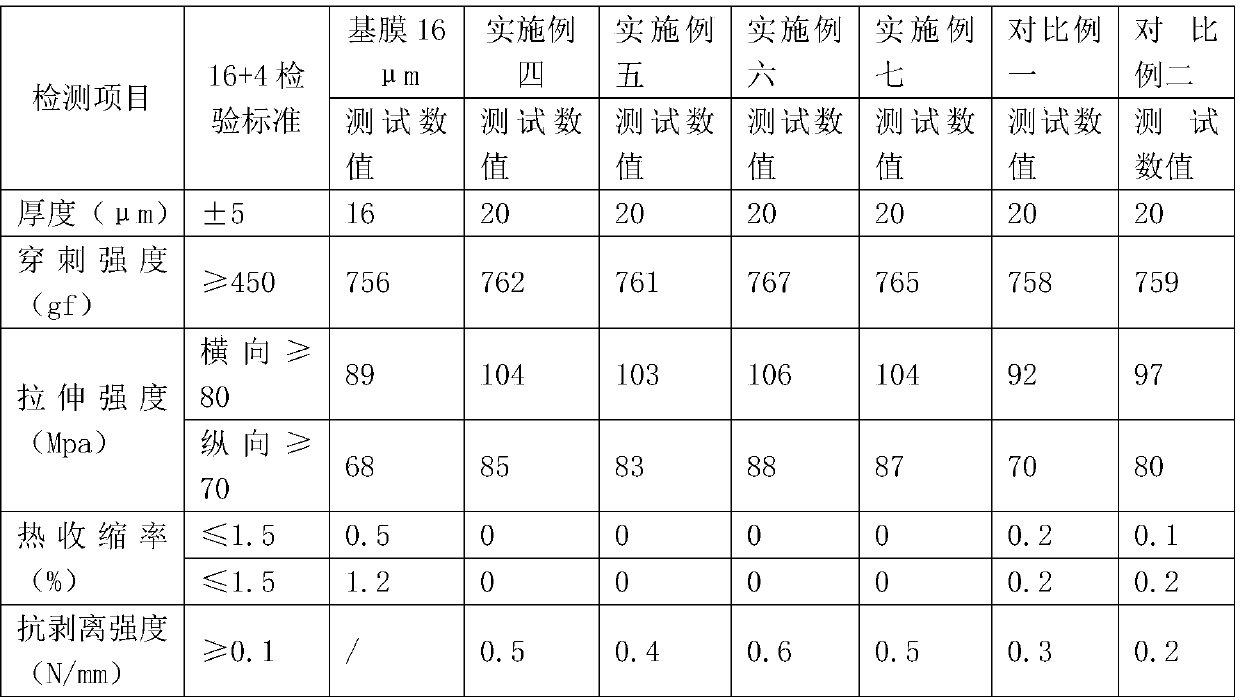

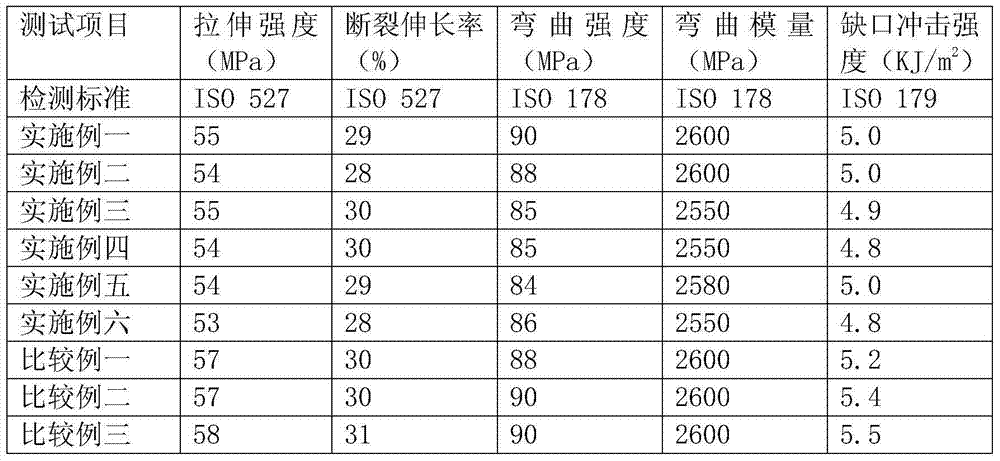

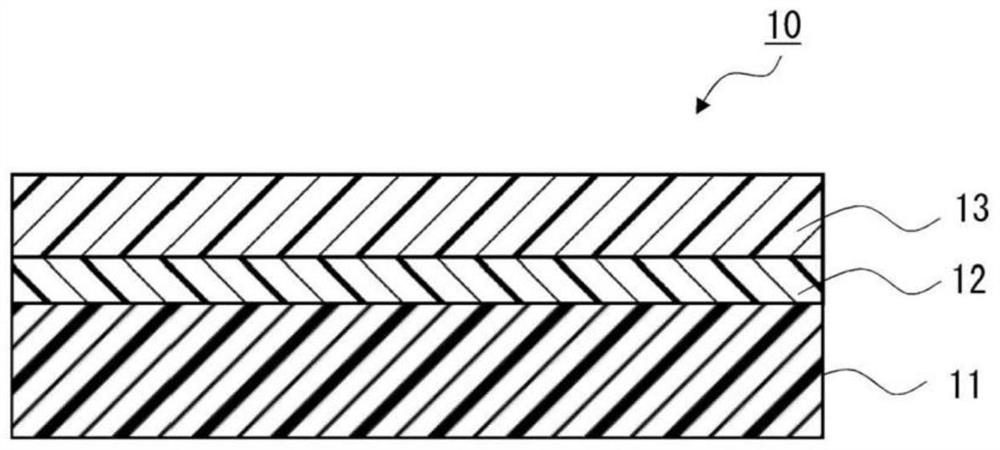

Preparation method of inorganic and organic composite coating diaphragm

InactiveCN110660949AExcellent overall performanceGood heat resistanceCell component detailsAqueous solutionPolyvinyl alcohol

The invention relates to a preparation method of an inorganic and organic composite coating diaphragm, and belongs to the technical field of lithium ion batteries. The preparation method comprises thefollowing steps: (1) preparing slurry: mixing 20-25 parts by weight of PVDF, 30-35 parts by weight of polyvinyl alcohol solution, 20-25 parts by weight of deionized water and 10-15 parts by weight ofa 1-1.5% CMC aqueous solution, adding 1-5 parts by weight of dispersants, 10-15 parts by weight of 1-1.5% CMC aqueous solution, 20-25 parts by weight of deionized water and 5-15 parts by weight of alumina powders, then, adding 1-3 parts by weight of coagulants and 0.5-1 part by weight of wetting agents, and carrying out stirring to obtain composite slurry; and (2) coating the composite slurry ona PE diaphragm, and carrying out drying in a drying oven at the temperature of 40-80 DEG C to obtain the inorganic and organic composite coating diaphragm. The diaphragm prepared by adopting the preparation method has excellent heat resistance, good mechanical tensile property and higher anti-stripping strength; and the method is simple and low in cost and meets use requirements of the lithium ionbattery.

Owner:宁波中科达新材料有限公司

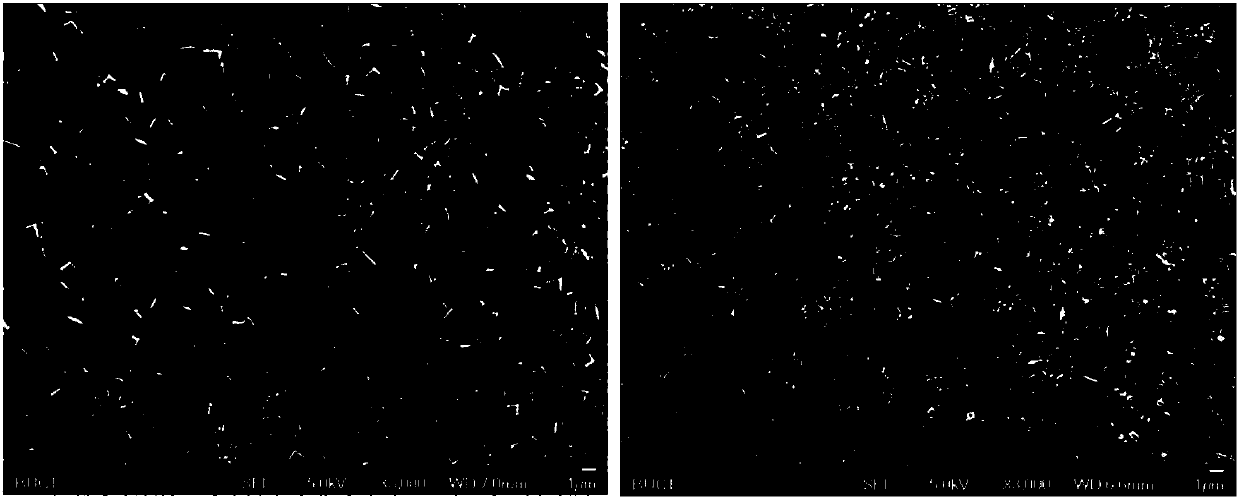

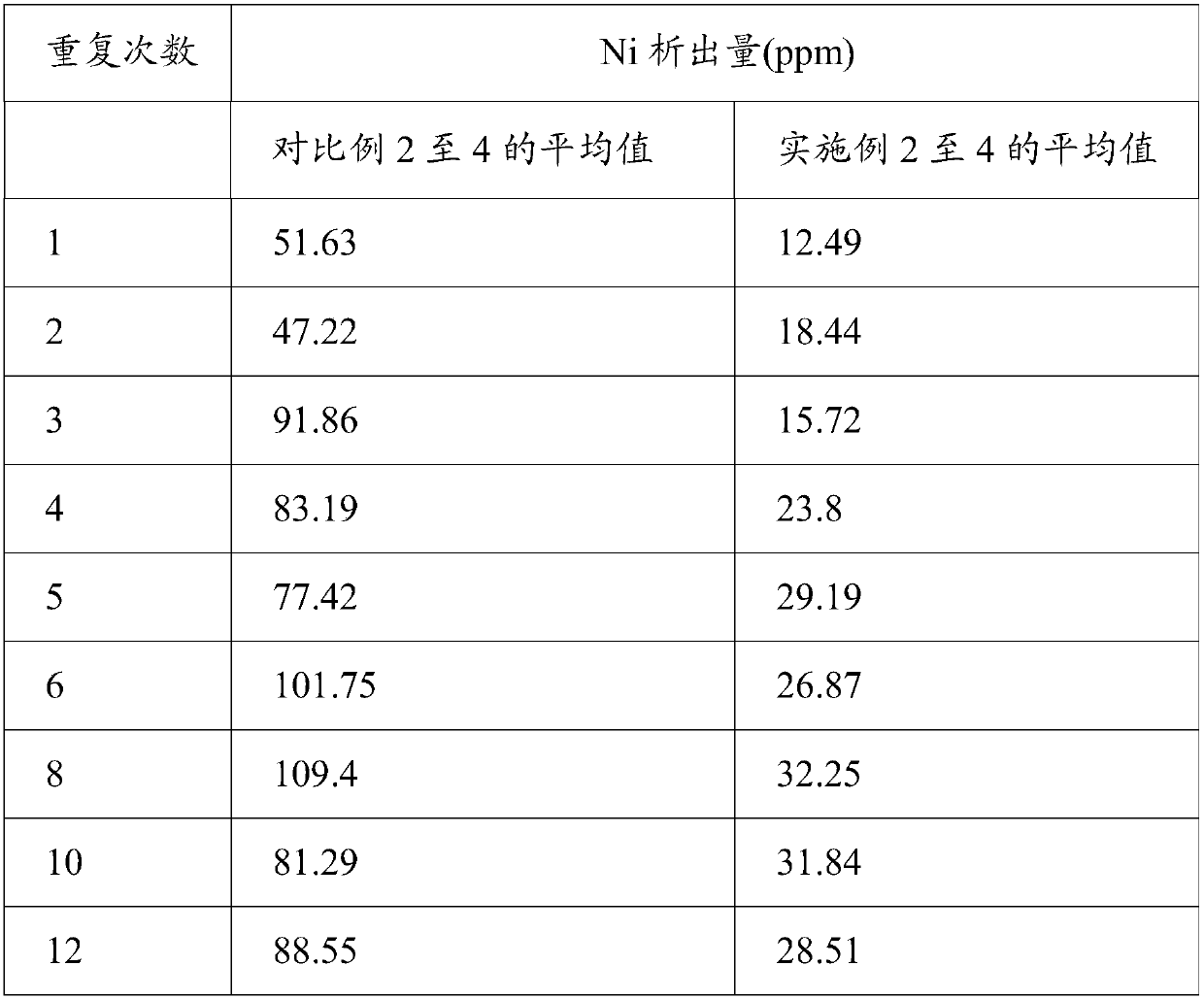

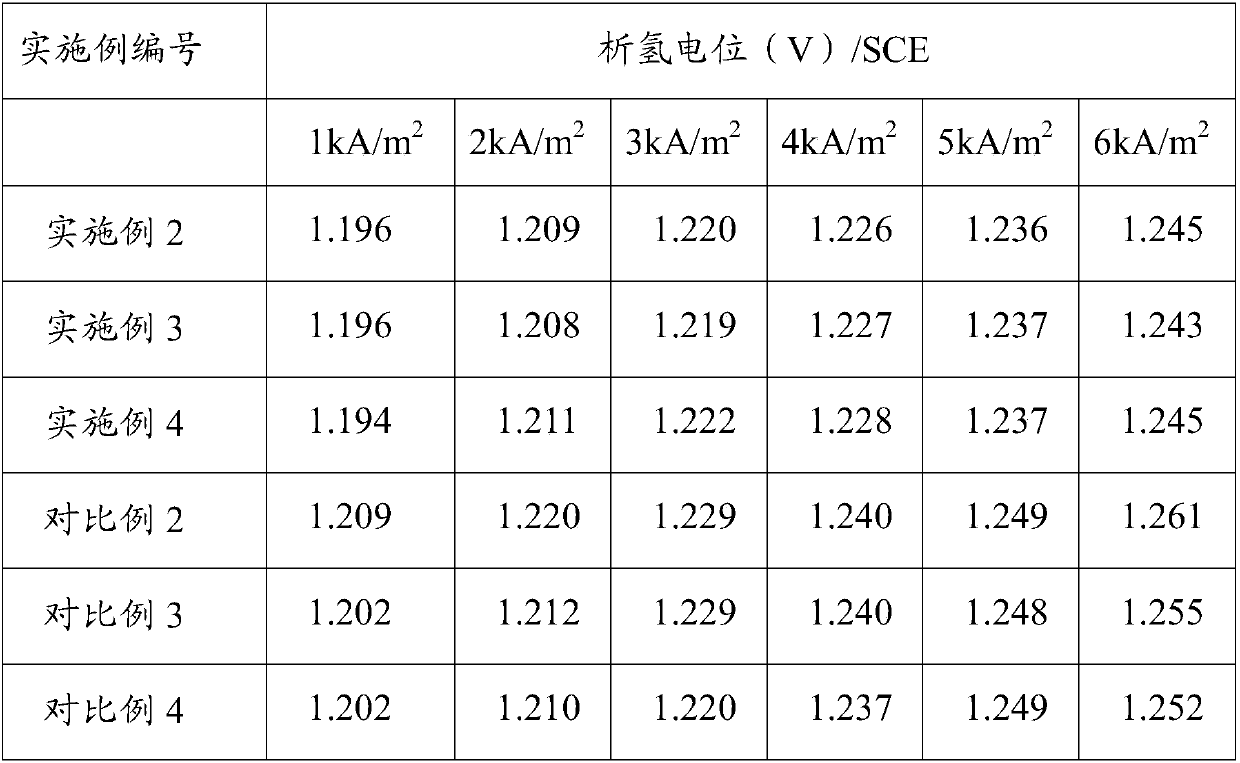

Hydrogenated active cathode and preparation method thereof and electrolytic tank with hydrogenated active cathode

The invention discloses a hydrogenated active cathode and a preparation method of the hydrogenated active cathode and an electrolytic tank with the hydrogenated active cathode. The hydrogenated activecathode comprises a conductive substrate and an active catalyst layer on the conductive substrate, and the active catalyst layer is directly formed on the surface of conductive substrate after heat treatment of nitric acid series nitrate. By means of the preparation method of the hydrogenated active cathode, the defect that the chlorine gas decomposed out in the process of heat treatment when utilizing a chloride solution as a coating solution has great harm to human body is overcome. The prepared catalyst layer of the hydrogenated active cathode is obtained by heat treatment of the nitric acid series nitrate solution with less corrosivity to a nickel base material in an oxygen atmosphere and the heat treatment of low-high-temperature two-stage burning is preferred, the preparation methodof the hydrogenated active cathode is simple, the prepared cathode is strong in corrosion resistance and is long in service life, low in electrode potential, excellent in catalytic activity and highin uniformity of the catalyst layer, and the electrolytic properties and electrocatalytic activity are both improved greatly.

Owner:BLUESTAR BEIJING CHEM MACHINERY

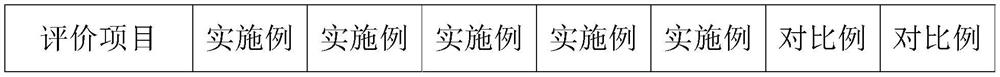

Anti-fog coating, preparation method thereof and anti-fog glass

ActiveCN114015317ANot easy to peel offRealize active anti-fogEpoxy resin coatingsHydrophilic monomerPolymer science

The invention relates to the technical field of automotive glass, in particular to an anti-fog coating, a preparation method of the anti-fog coating and anti-fog glass. The anti-fog coating is prepared from the following raw materials: a hydrophilic copolymer, epoxy resin, a coupling agent, a curing agent and a first solvent, the hydrophilic copolymer is prepared from the following raw materials: a hydrophilic monomer, an initiator and a second solvent; the solubility of the epoxy resin in water is greater than or equal to 90%; the solubility of the hydrophilic copolymer in water is greater than or equal to 90%. The anti-fog coating disclosed by the invention can be directly coated on a glass substrate in a single layer, the production process is simplified, the production cost is reduced, and the antifogging coating has a very good antifogging effect and is not easy to peel off.

Owner:FUYAO GLASS IND GROUP CO LTD

Acrylic based paint for polymeric surfaces

InactiveUS7531032B2Desired rheologyDesired viscosityNon-fibrous pulp additionPaper coatingPolymeric surfaceElastomer

Owner:MATTEL INC

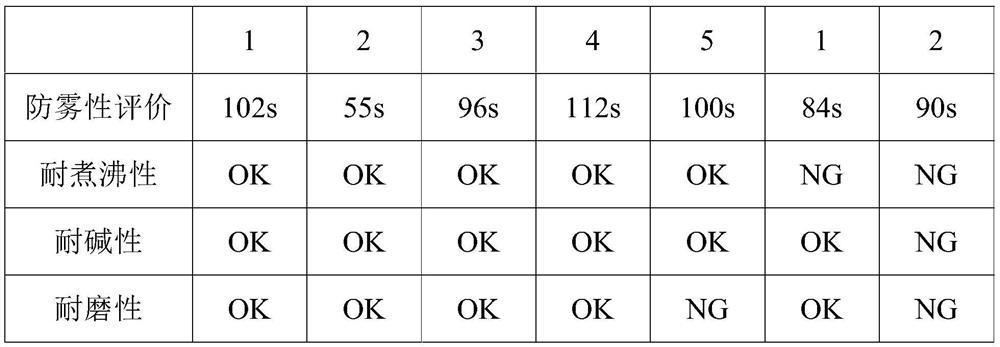

Plating compositions for electrolytic copper deposition, its use and a method for electrolytically depositing a copper or copper alloy layer onto at least one surface of a substrate

The present invention relates to a plating composition for electrolytic copper deposition, comprising copper ions, halide ions and at least one acid, at least one benzothiazole compound, at least onephenanzine dye and at least one ethanediamine derivative. The present invention further concerns the use of above plating composition and a method for electrolytically depositing a copper or copper alloy layer onto at least one surface of a substrate.

Owner:ATOTECH DEUT GMBH

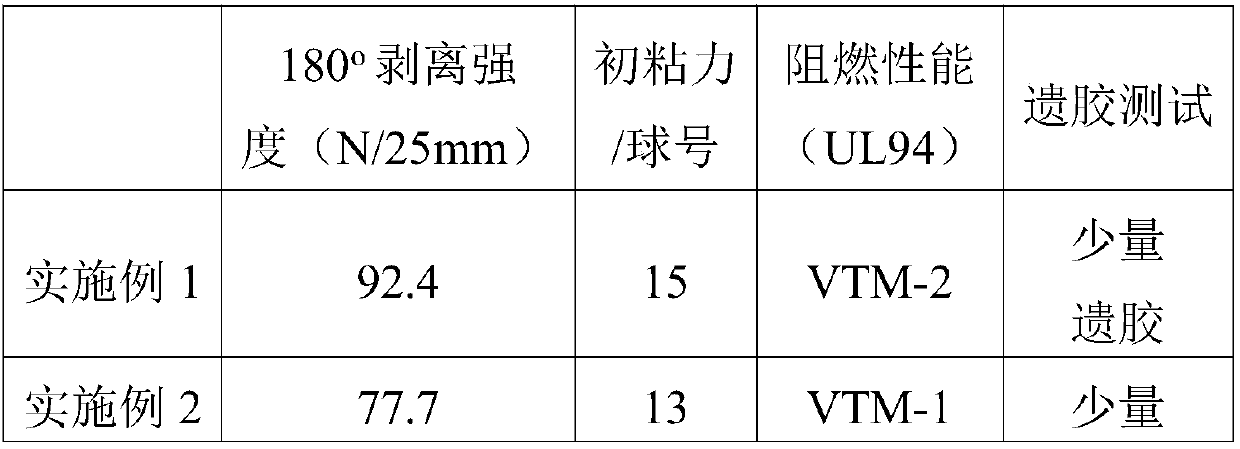

Removable vehicle paster and preparation method and application thereof

InactiveCN107603508AEasy to removeEasy to integrateNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedBenzoyl peroxide

The invention belongs to the technical field of materials and especially relates to a removable vehicle paster and a preparation method and application thereof. The vehicle paster successively contains a water-based ink-jet ink-drawing layer, a primer layer, a PVC layer, a removable pressure sensitive adhesive layer and release paper. The water-based ink-jet ink-drawing layer is obtained by mixingand stirring 17-20% of water-based ink-drawing resin, 0.5-1% of a wetting agent and 79-82.5% of water. The primer layer is obtained by mixing and stirring 10-20% of water-based resin, 0.5-1% of a wetting agent and 89.5-79% of water. The removable pressure sensitive adhesive layer is composed of 20-30% of butyl acrylate, 1.5-3% of acrylic acid, 15-23% of methyl methacrylate, 0.5-2% of benzoyl peroxide, 18-30% of toluene, 27-40% of ethyl acetate, 1-5% of a curing agent, 1-5% of latex powder and 2-6% of nano-attapulgite. The vehicle paster can 100% remove residual gum, has good curved surface adhesion, and has no bubble, crease or edge warping phenomena.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

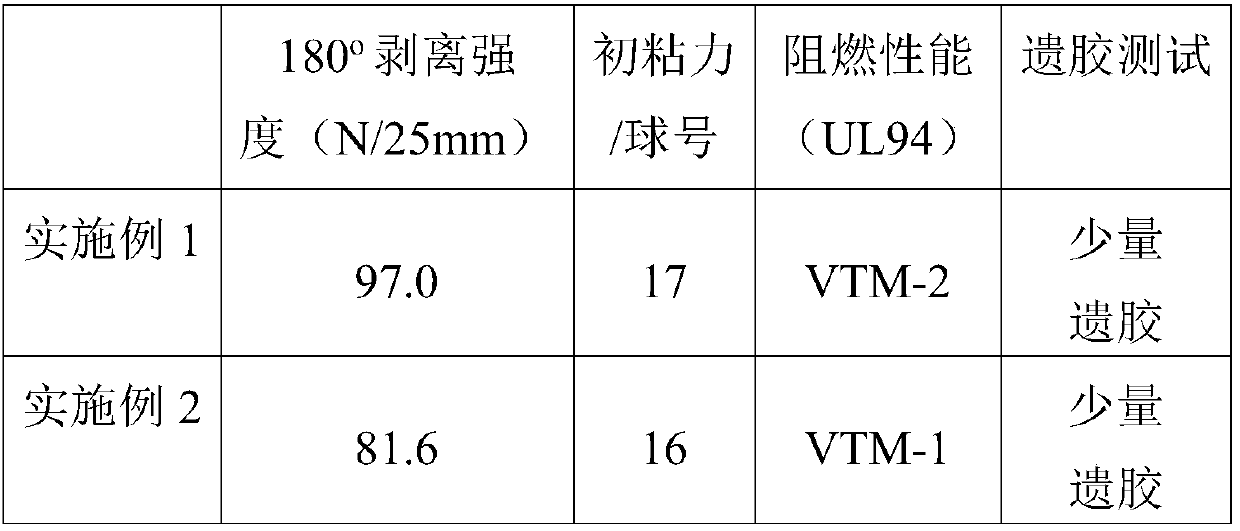

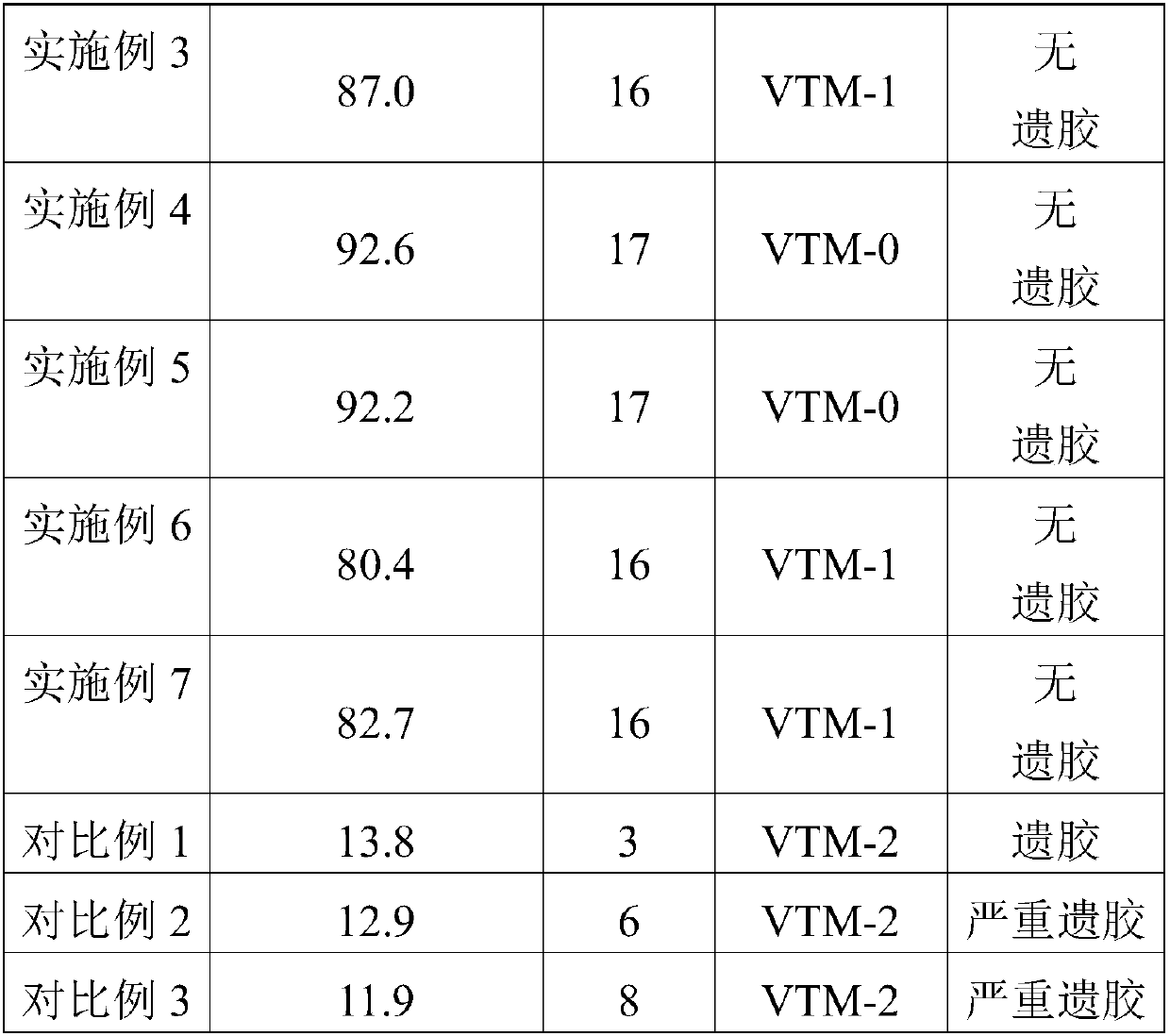

Water-based flame-retardant white bright back glue PVC and preparation method thereof

InactiveCN107603503AHigh color reproductionGuaranteed flame retardant performanceFireproof paintsNon-macromolecular adhesive additivesPolymer scienceFireproofing

The invention relates to digital image receiving materials, especially to water-based flame-retardant white bright back glue PVC. The water-based flame-retardant white bright back glue PVC comprises aflame-retardant coating, a white PVC layer, a flame-retardant glue layer and a release white silicon paper layer, which are arranged from top to bottom. The flame-retardant glue layer is composed ofthe following ingredients (by weight): 38-50% of butyl acrylate, 6-12% of methyl methacrylate, 2-6% of acrylic acid, 4-8% of propenol, 10-17% of a phosphorus-containing acrylic monomer, 3-8% of melamine, 0.1-0.3% of alkyl sulfate, 3-8% of a curing agent, 2-4% of an initiator, 1-5% of latex powder and 2-6% of nanometer attapulgite. The flame retardant property of the water-based flame-retardant white bright back glue PVC can reach the fireproofing grade of VTM-2, has high color reduction degree, 100% removes residual glue, and can be applied to water-based spray painting and portray printing equipment.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

Heat insulation additive for building coating and preparation method

InactiveCN109161246AGood surface adhesionNot easy to fall offReflecting/signal paintsEmulsionWeather resistance

The invention relates to a heat insulation additive for a building coating and a preparation method, and belongs to the field of preparation of a building coating. The preparation method of the heat insulation additive for the building coating particularly comprises the following steps: a, adding poly vinyl alcohol cryogel, an emulsifier and sodium bicarbonate into water to mix, warming, stirringand adding hollow glass microspheres; and b, preparing a precursor solution by vinyl acetate, acrylic acid and butyl acrylate, adding the precursor solution into prepared mixed emulsion, heating to perform a thermal reaction, carrying out initiated polymerization, then cooling to the room temperature, regulating a pH value into 7, then carrying out vacuum drying to obtain enveloped hollow glass microsphere microcapsules, that is, the heat insulation additive for the building coating. The heat insulation additive for the building coating, which is prepared by the preparation method disclosed bythe invention, can improve reflectivity and weather resistance of the coating, reinforce a heat insulation effect of the coating and have the advantages of environmental protection and energy saving.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Polyester thin film manufacturing method

The invention discloses a polyester thin film manufacturing method. According to the polyester thin film manufacturing method, drying treatment is performed after the blending of raw materials, thereby lowering the possibility that the raw materials are degraded due to the presence of water when being machined, and improving the product quality; the temperature of an extruded molten fluid is set to 265-295 DEG C and the temperature of a quenching roller is set to 10-20 DEG C, thereby ensuring the uniform shape of a casting piece which is formed by adopting the raw materials, and providing a foundation for the stretching step; hot setting is performed after the stretching, and then cooling is performed, thereby reducing the internal stress generated during the stretching and then obtaining a high-quality polyester thin film; and double-sided corona treatment is performed after the polyester thin film is stretched, thereby enhancing the surface adhesive ability of the polyester thin film.

Owner:中山市泓溢薄膜科技有限公司

Preparation method of water-based flame-retardant grey gum type back glue PVC

InactiveCN107603504AHigh color reproductionGuaranteed flame retardant performanceFireproof paintsNon-macromolecular adhesive additivesWater basedFireproofing

The invention relates to digital image receiving materials, especially to a preparation method of water-based flame-retardant grey gum type back glue PVC. The preparation method of the water-based flame-retardant grey gum type back glue PVC comprises the following steps: (1) preparing a flame-retardant coating; (2) preparing a flame-retardant glue layer; (3) coating a white PVC layer with 15-30 g / m<2> of the flame-retardant coating, drying, coating the other surface of the white PVC layer with 15-30 g / m<2> of the flame-retardant glue layer at the coating speed of 20-40 m / min, drying, gluing the white PVC layer with the release white silicon paper layer, and rolling. The flame retardant property of the water-based flame-retardant grey gum type back glue PVC prepared by the above preparationmethod can reach fireproofing grade of VTM-2; and the product has high color reduction degree, 100% removes residual glue and can be applied to water-based spray painting and portray printing equipment.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

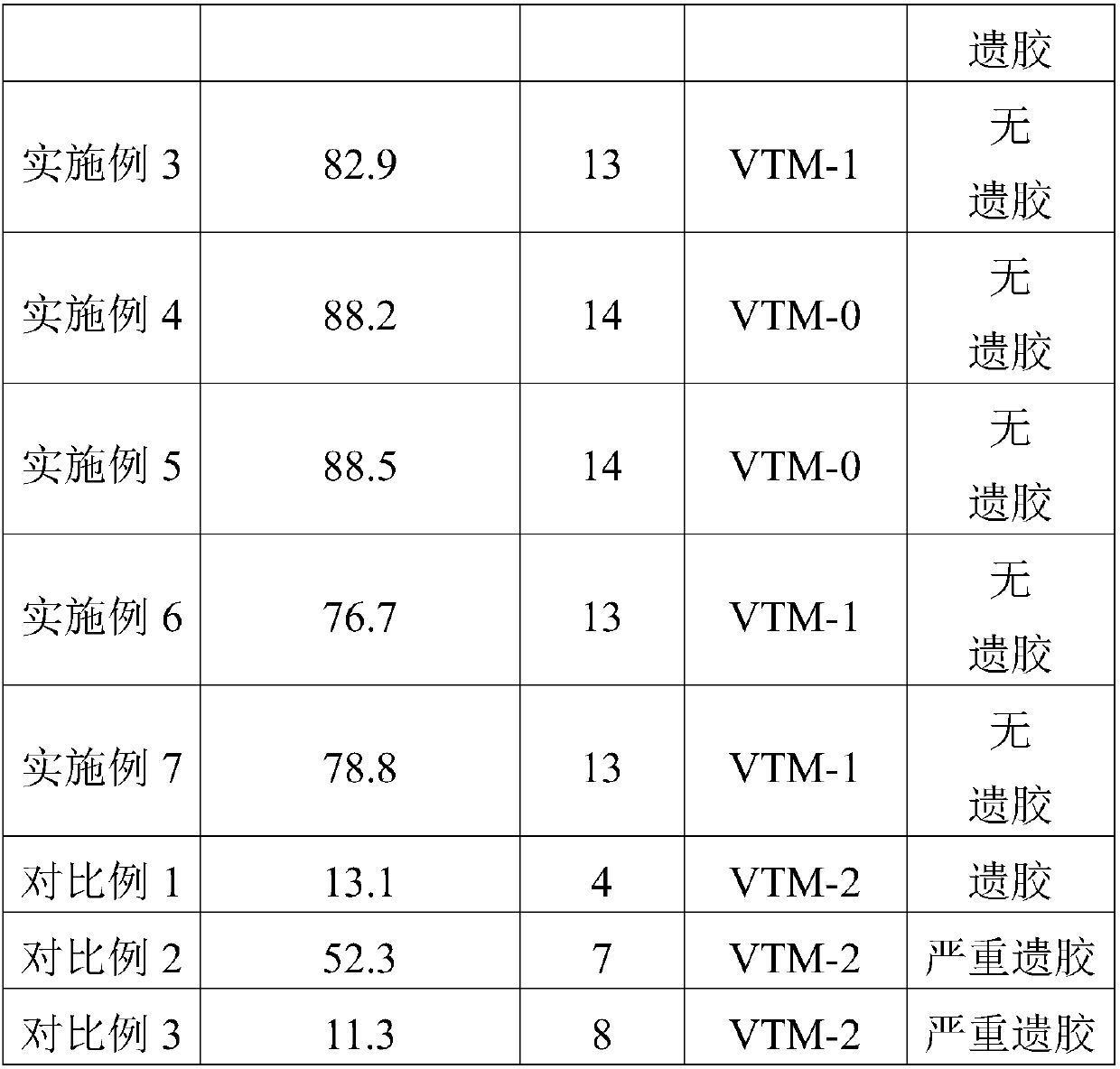

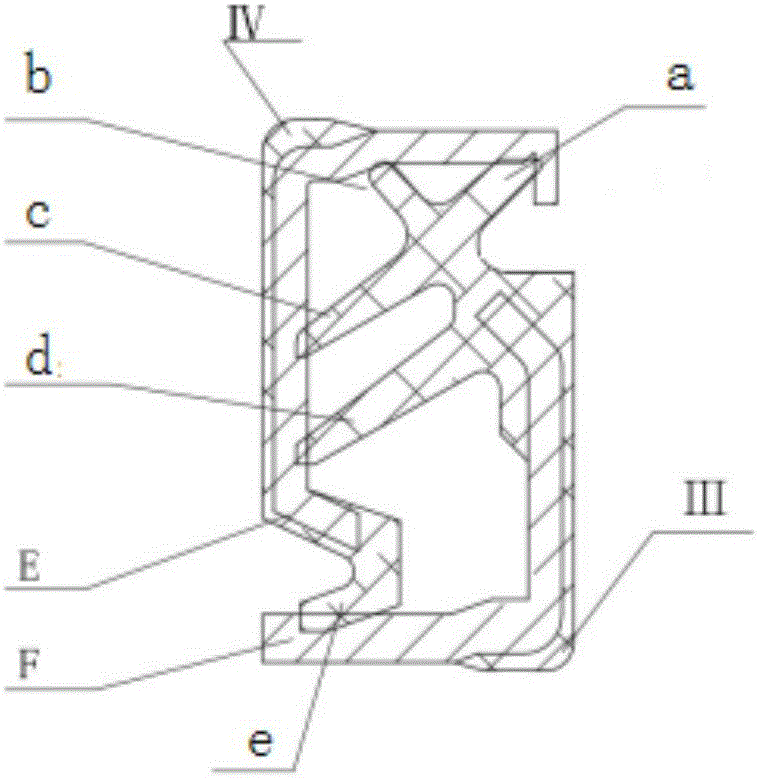

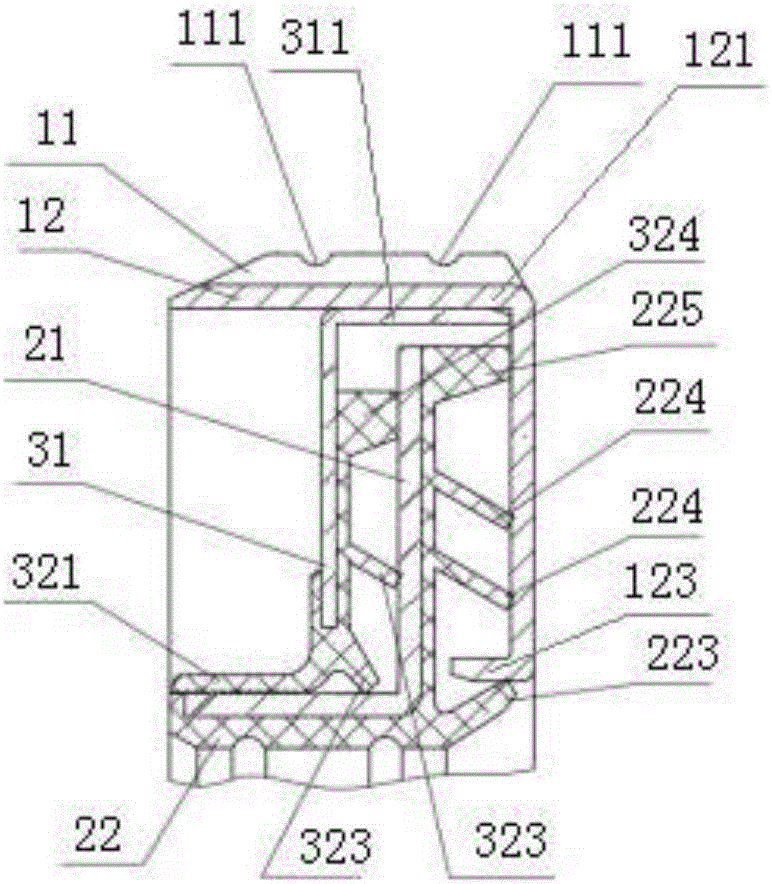

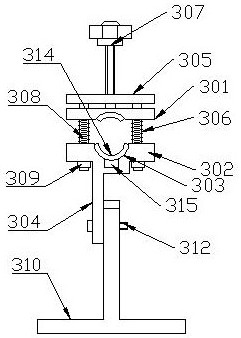

Sealing device for hub bearing unit of agricultural machine

InactiveCN106168257AImprove sealingReduce extrusion pressureAgriculture tools and machinesShaftsAgricultural engineeringFailure causes

The invention discloses a sealing device for a hub bearing unit of an agricultural machine. The sealing device comprises an outer side sealing assembly clamped on the inner wall of an oil seal cavity, a middle sealing assembly sleeving a rotating shaft and an inner side sealing assembly clamped in the outer side sealing assembly. The inner side sealing assembly is closer to the bearing unit than the middle sealing assembly. The sealing device for the hub bearing unit of the agricultural machine is more reliable in sealing performance, so that the sealing reliability of the sealing device for the hub bearing unit of the agricultural machine under poor outdoor operation conditions is improved, hub unit failures caused by sealing failure are reduced, and production efficiency of the agricultural machine is improved.

Owner:苏州哥特机械有限公司

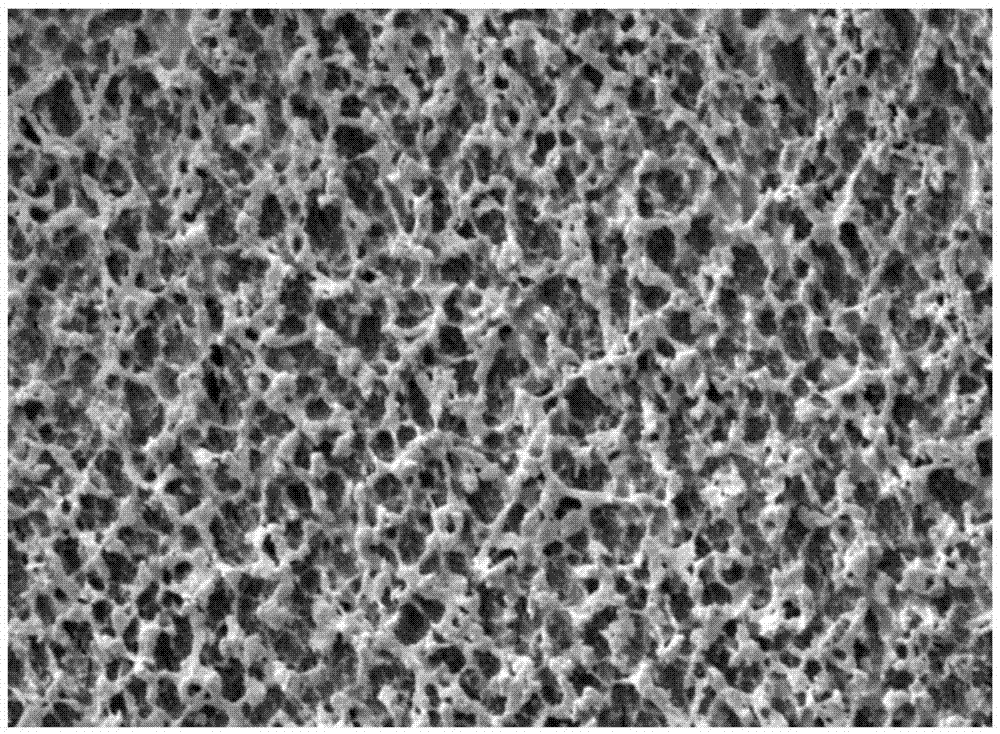

Polyformaldehyde product surface processing method

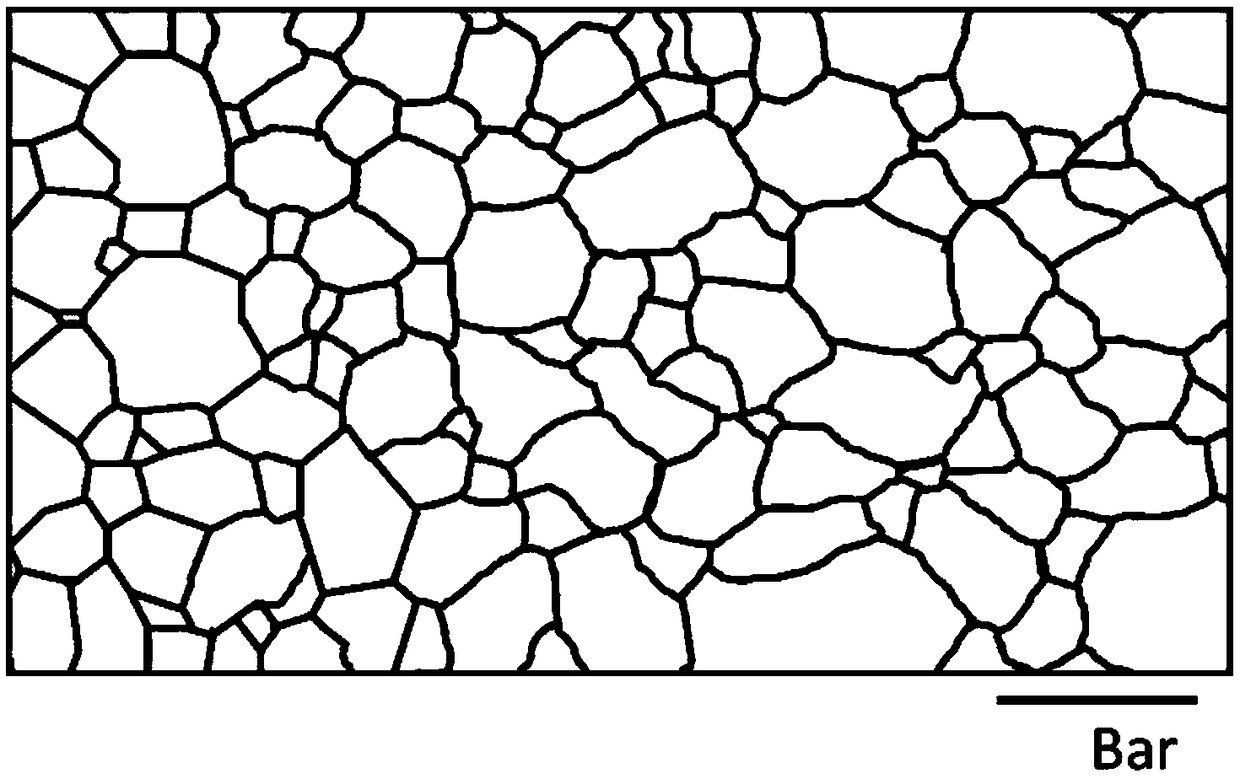

ActiveCN103757677AImprove bindingExtended service lifePretreated surfacesCoatingsElectroplatingCrystallization

A disclosed polyformaldehyde product surface processing method comprises: performing roughening treatment on the surface of a polyformaldehyde product, destroying the crystallization zone of the surface, cleaning the polyformaldehyde product surface subjected to roughening treatment, and immersing in an acid solution to perform surface acidifying treatment, so as to form a continuous netted micropore structure on the surface of the polyformaldehyde product. According to the processing method, the mechanical roughening manner is firstly employed for performing roughening treatment on the polyformaldehyde product, then the acid solution is utilized to process the polyformaldehyde product for forming the netted micropore structure on the product surface, and by utilizing the netted micropore structure, coating or electroplated-layer molecules permeate pores and an fixedly-connected integral body is formed by the molecules and polyformaldehyde, so that the surface adhesion property of the polyformaldehyde product is improved, the bonding force between the polyformaldehyde product surface and paint or an electroplating material is improved, the application of polyformaldehyde is enlarged, and the service life of a coating or an electroplated layer on the surface of the polyformaldehyde product is prolonged.

Owner:YUNNAN YUNTIANHUA

Ultraviolet light-cured PVC (polyvinyl chloride) anti-dirt paint

InactiveCN103509458AGood adhesionGood anti-dirty effectAntifouling/underwater paintsPaints with biocidesChemistry(Hydroxyethyl)methacrylate

The invention discloses an ultraviolet light-cured PVC (polyvinyl chloride) anti-dirt paint. The anti-dirt paint comprises the following raw materials in percentage by weight: 20%-25% of aliphatic polyurethane diacrylate, 20%-23% of aliphatic polyurethane tetraacrylate, 8%-10% of TMPTA (trimethylolpropane triacrylate), 8%-15% of HEMA (hydroxyethyl methacrylate), 10%-15% of tetrafluoropropyl acrylate, 10%-15% of TPGDA (tripropylene glycol diacrylate) and 0.3%-0.5% of leveling agent. The paint disclosed by the invention has the advantages of good surface adhesion and relatively good anti-dirt effect against PVC substrates.

Owner:袁吉昌

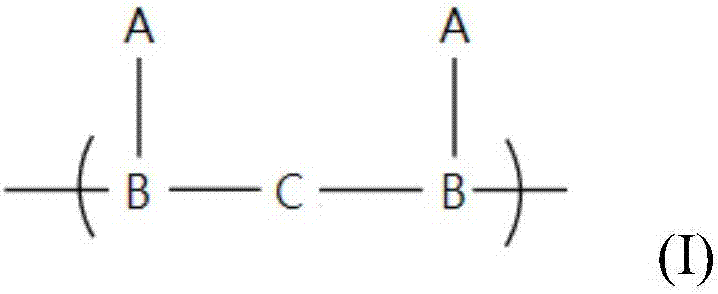

Polyurethane-based hihg-molecular UV absorber

InactiveCN107540806AGood surface adhesionImprove light fastnessOrganic chemistryLight resistant fibresPolymer sciencePolyol

The invention relates to a polyurethane-based high-molecular absorber, a polymer of which is obtained by reacting a UV absorber having a reactive hydrogen with a polyisocyanate and a diol or polyol.The weight average molecular weight of the polyurethane-based high-molecular UV absorber is in a range of 10,000 to 200,000.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

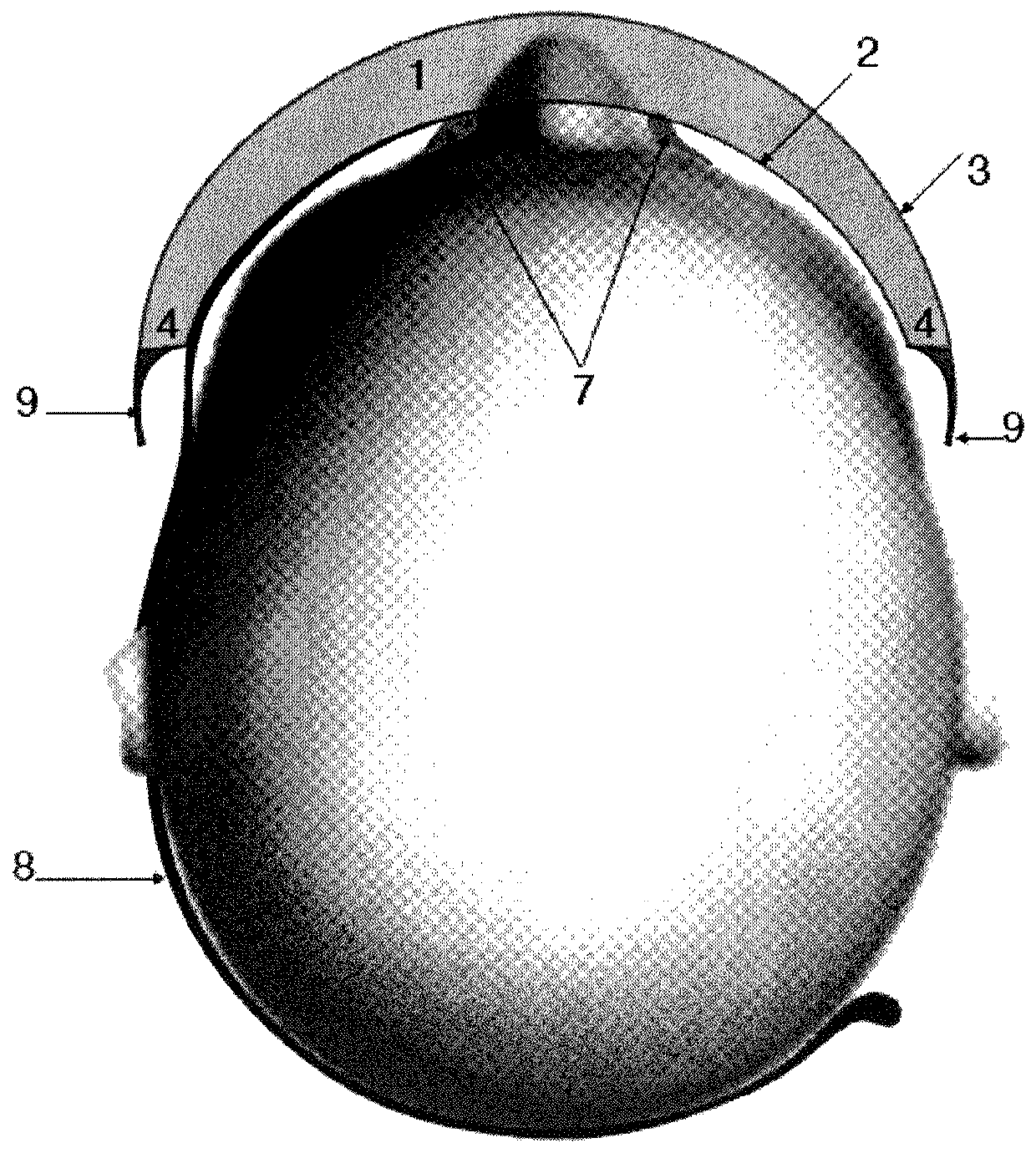

Structured barrier-exhaust-type medical mask with support

PendingCN110996833APrevent penetrationSolve pressing problemsProtective garmentApparatus providing aseptic surgical environmentPersonal protective equipmentFacial region

A structured barrier-exhaust-type mask with a support relates to personal protective equipment, and specifically to masks intended primarily for use in the field of medicine. The present mask can serve as all-round environmental and hygiene protection for doctor and patient during the delivery of medical care of any degree of complexity, including long surgical procedures, and also as personal protection for civilians against airborne infection. The mask completely prevents exhaled air from passing between doctor and patient, and exhausts exhaled air in a given direction. The mask comprises ahollow structure which forms a mask cavity in the facial region and is designed in the form of a channel having an inlet and an outlet for the passage of an air flow, said mask being characterized inthat the inner and outer walls of the structure are made of an air-impermeable material, and a support is provided between the surface of the face and the inner wall of the structure, said support being in the form of an ergonomic cushion around the mouth region, or an arc running along the lower or upper jaw.

Owner:M 航空有限责任公司

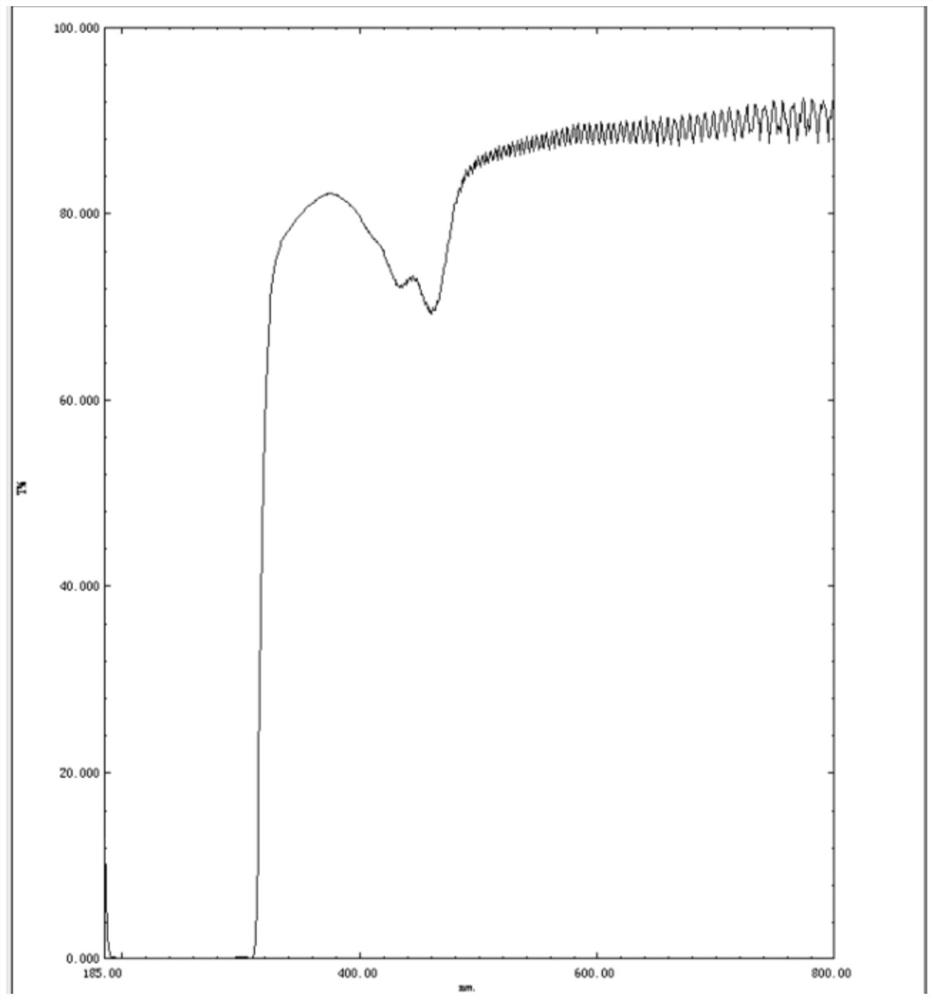

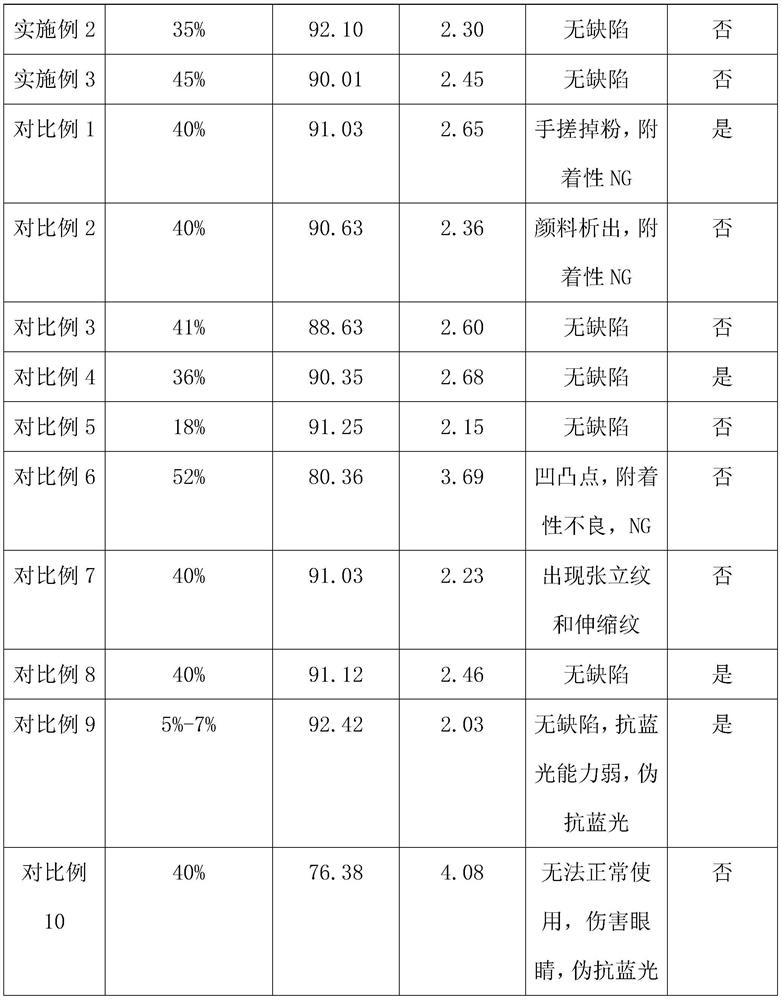

Blue-light-resistant coating for trace coating

The invention discloses an anti-blue-light coating for trace coating. The anti-blue-light coating comprises resin, a solvent, a pigment and a curing agent; the mass of the solvent is equivalent to 90-95 times of the mass of the resin; the mass of the anti-blue light pigment is equivalent to 20-40% of the mass of the resin, and the mass of the curing agent is equivalent to 2-7% of the mass of the resin; the mass of the anti-blue light pigment accounts for 0.3-0.4% of the total mass of the coating; and the resin is polyester resin containing hydroxyl-terminated functional groups. On the premise that the solid content and the use amount of the anti-blue light pigment are greatly reduced, the blue-light-resistant coating disclosed by the invention can keep excellent blue-light-resistant performance, the cost is effectively reduced, the economical efficiency and the environmental protection property are improved, and the blue-light-resistant coating has wide prospects and social requirements.

Owner:TAIHU JINZHANG TECH CO LTD

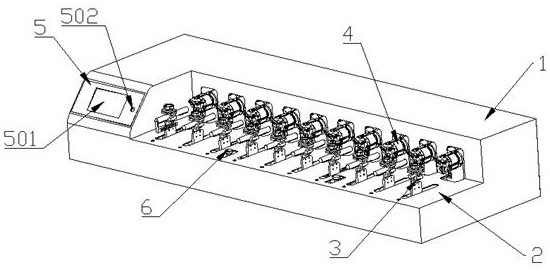

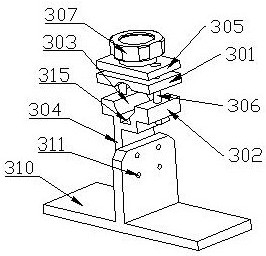

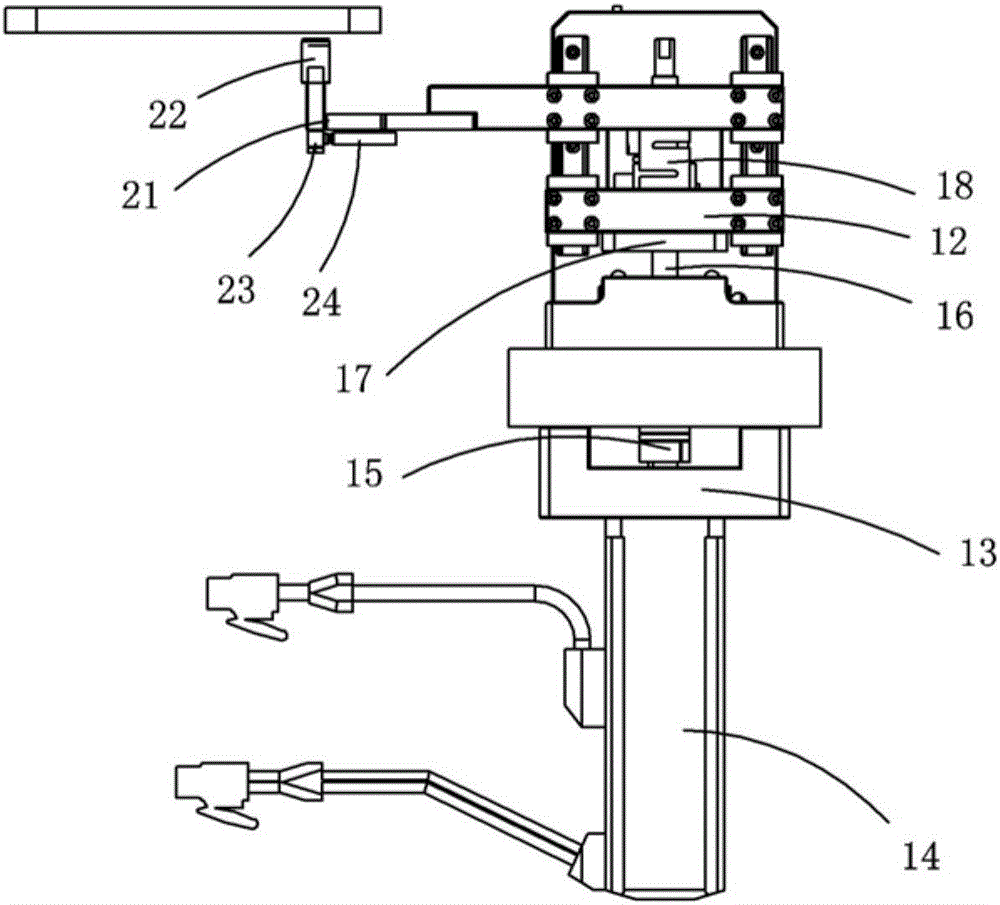

Pen type insulin syringe detection pretreatment equipment

ActiveCN113459005BGuaranteed stabilityGuaranteed reproducibilityInfusion syringesMedical devicesLinear motionEngineering

The invention discloses a pen-type insulin injector detection pretreatment driving tool, which belongs to the technical field of medical equipment inspection, and its structure includes a rotation system and a linear motion system. Carry out linear motion; the rotary system includes a chuck, the front of the chuck is used to clamp the pen-type insulin syringe, and the rear of the chuck is connected to the first rotary drive mechanism; the linear motion system includes a linear guide rail and a slider, and the top of the slider and the rotary system Fixed connection, the bottom of the slider is movably installed on the linear guide rail and can move along the linear guide rail. The technical scheme of the example of the present invention can drive the pen-type insulin syringe to rotate and advance, assist the pretreatment before the injection dose accuracy inspection, save manpower and improve efficiency.

Owner:山东省医疗器械和药品包装检验研究院

A polishing agent used for automobiles and a preparing method thereof

InactiveCN106554723AQuick clearGood for re-sprayingPolishing compositions with abrasivesPolyethylene glycolSalicylic acid

A polishing agent used for automobiles is disclosed. The polishing agent is prepared from, by weight, 8-15 parts of citric acid, 10-20 parts of glacial acetic acid, 5-10 parts of cinnamic acid, 5-12 parts of salicylic acid, 20-50 parts of glycerol, 30-80 parts of polyethylene glycol 8000, 100-200 parts of divalent acid ester, 2-8 parts of polyoxyethylene oleyl ether, 5-12 parts of nanometer titanium dioxide, 3-5 parts of nanometer silica, 5-9 parts of nanometer zinc oxide and 20-30 parts of an auxiliary agent. The citric acid, the glacial acetic acid, the cinnamic acid and the salicylic acid which are diacids and low in corrosion are adopted to replace strong acids and strong alkalis and are dissolved into the divalent acid ester, and therefore oxides on the surface of automobile paint can be rapidly cleaned. The nanometer titanium dioxide, the nanometer silica and the nanometer zinc oxide can increase surface adhesion force of the polishing agent and improve activity of the polishing agent. Through cooperation of the auxiliary agent, paint surfaces can be rapidly polished through friction and a protection film is formed on the surface layer of the paint.

Owner:广西钱隆投资管理有限公司

UV light curing pvc anti-fouling paint

InactiveCN103509458BImprove dirt resistanceEasy to useAntifouling/underwater paintsPaints with biocidesTripropylene glycol(Hydroxyethyl)methacrylate

The invention discloses an ultraviolet light-cured PVC (polyvinyl chloride) anti-dirt paint. The anti-dirt paint comprises the following raw materials in percentage by weight: 20%-25% of aliphatic polyurethane diacrylate, 20%-23% of aliphatic polyurethane tetraacrylate, 8%-10% of TMPTA (trimethylolpropane triacrylate), 8%-15% of HEMA (hydroxyethyl methacrylate), 10%-15% of tetrafluoropropyl acrylate, 10%-15% of TPGDA (tripropylene glycol diacrylate) and 0.3%-0.5% of leveling agent. The paint disclosed by the invention has the advantages of good surface adhesion and relatively good anti-dirt effect against PVC substrates.

Owner:袁吉昌

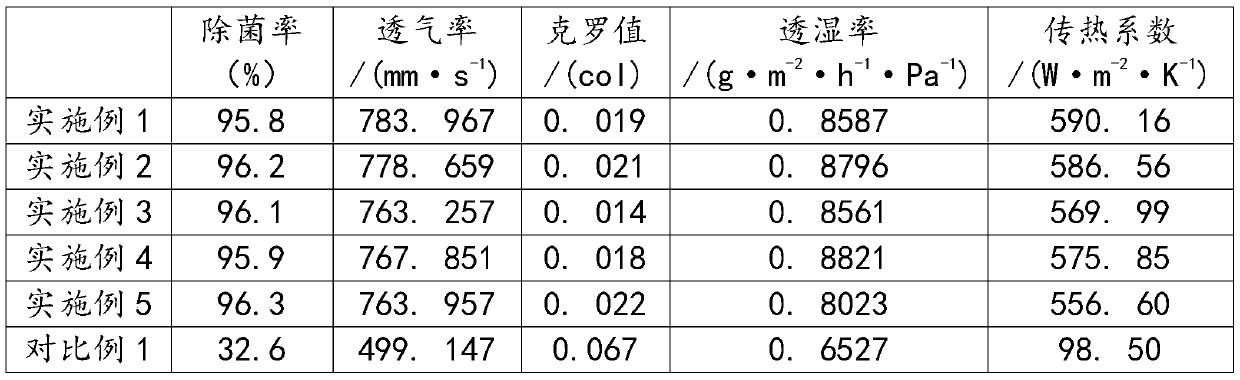

Breathable textile fabric and preparation method thereof

PendingCN111270386AImprove breathabilityImprove comfortBiochemical treatment with enzymes/microorganismsWoven fabricsPolyesterPolymer science

The invention relates to the field of fabric, in particular to a breathable textile fabric and a preparation method thereof. The breathable textile fabric comprises interwoven antibacterial warp yarnraw silk, weft yarn raw silk and second warp yarn raw silk; based on parts by weight, the antibacterial warp yarn interwoven raw silk comprises 4-10 parts of absorbent fibers, 3-9 parts of jute fibers, 2-4 parts of silk fibers and 2-4 parts of antibacterial coating; the weft yarn raw silk comprises 5-12 parts of ultra-fine activated carbon fibers, 4-12 parts of polyester fibers, 3-9 parts of aramid fibers and 1-3 parts of ramie fibers; and the second warp yarn raw silk comprises 3-9 parts of nano carbon fibers, 3-8 parts of bamboo charcoal fibers and 2-6 parts of 15D polyester staple fibers. According to the breathable textile fabric provided by the invention, the component compatibility of the wrap yarns and the weft yarns of the fabric are limited, so that the obtained textile fabric ishigh in air permeability and comfort, simultaneously has the functions of absorbing sweat and sterilizing clothes, can reduce the probability of occurrence of peculiar smell, and can effectively prolong the service life of clothes.

Owner:JIANGXI INST OF FASHION TECH

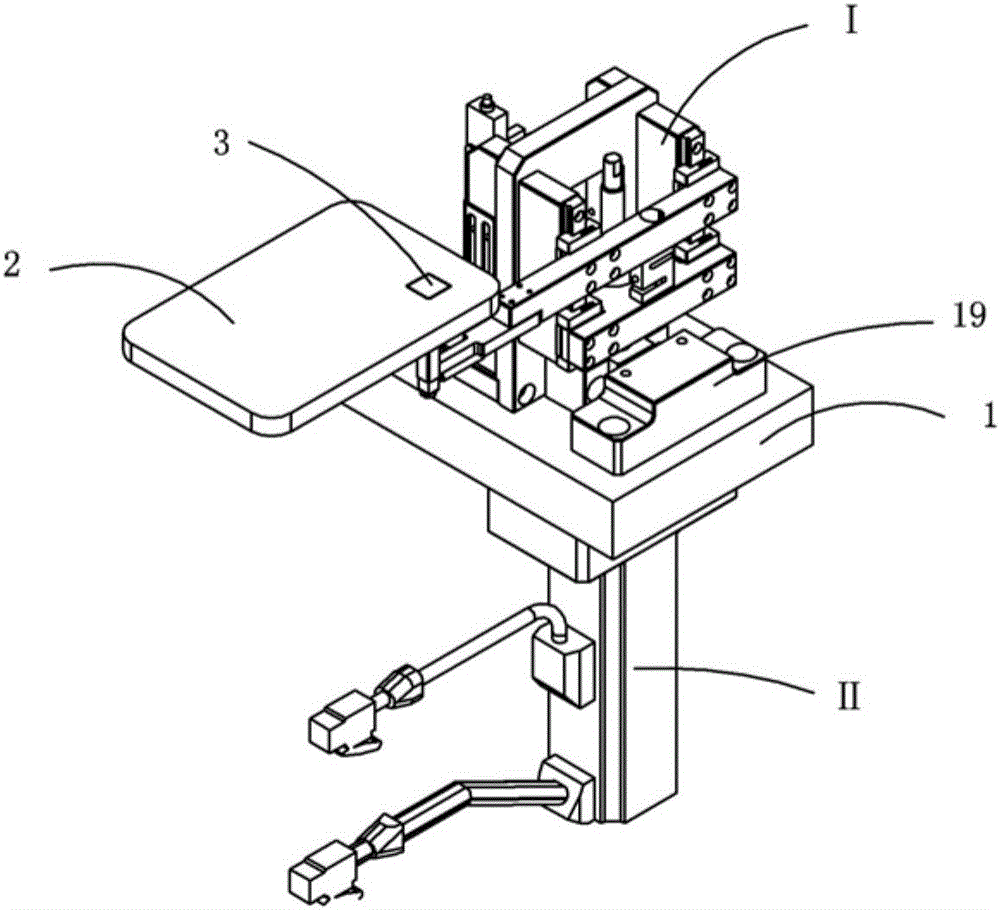

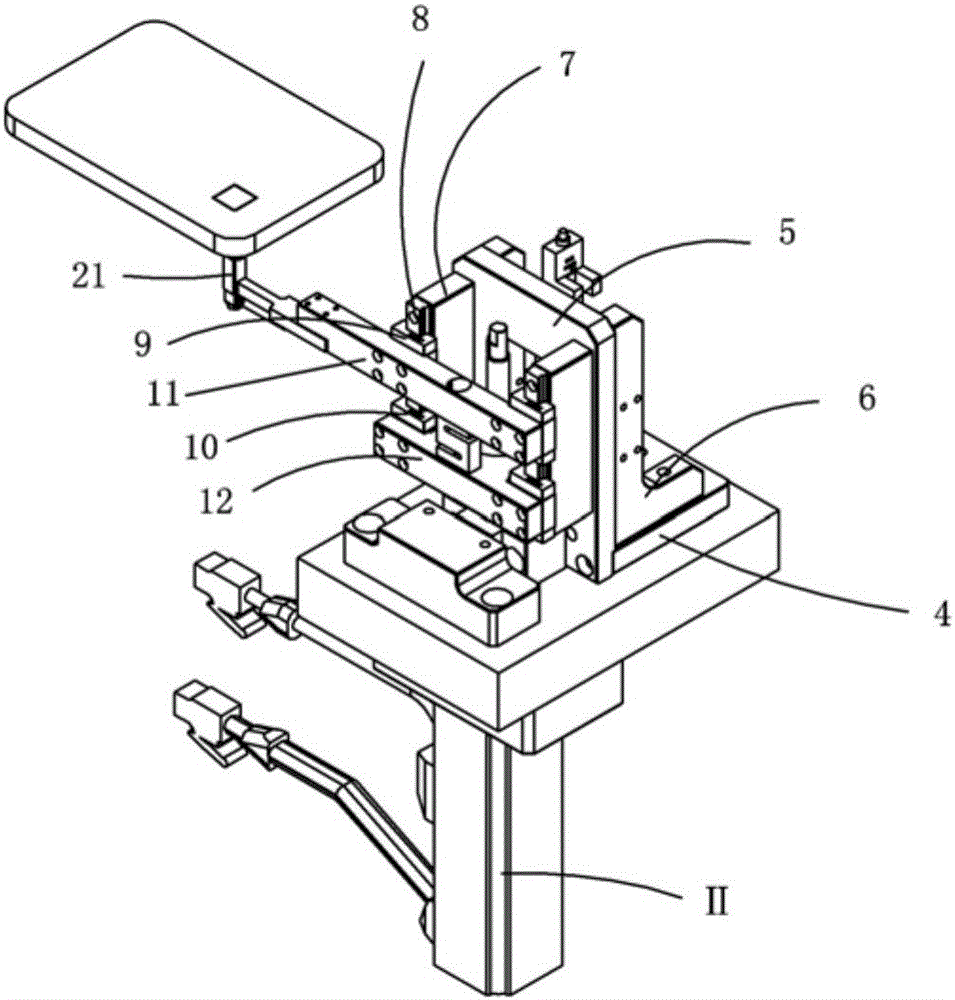

Positioning device based on push-pull test and positioning method thereof

ActiveCN105945836APrecise positioningGood surface adhesionMaterial strength using tensile/compressive forcesWork holdersKey pressingPush pull

The invention relates to a positioning device based on a push-pull test and a positioning method. A sliding assembly is mounted on the upper portion of a mounting plate. A connecting plate and an adsorption base connected with the connecting plate through a force sensor are arranged on the sliding assembly. A driving device is arranged on the mounting plate. An adsorption support is connected to the bottom of the left end of the adsorption base. A cylindrical rubber-coated suction nozzle is arranged at the upper end of the adsorption support, and the lower end of the adsorption support is connected with an air pipe through a miniature air circuit connector. The driving device drives the connecting plate to ascend so as to drive the cylindrical rubber-coated suction nozzle to ascend to make contact with keys, the keys are subjected to adsorption force and tension and pressure from the cylindrical rubber-coated suction nozzle to generate friction force F1, and the force sensor feeds back the magnitude of the friction force F1 in real time. Friction force F2 is generated when an upper panel moves relative to the keys, when the friction force F1 is greater than the friction force F2, the keys are in a static state, the friction force F2 can be overcome when the upper panel moves relative to the keys, and therefore the keys and the upper panel are aligned, and the keys are reliably positioned.

Owner:BOZHON PRECISION IND TECH CO LTD

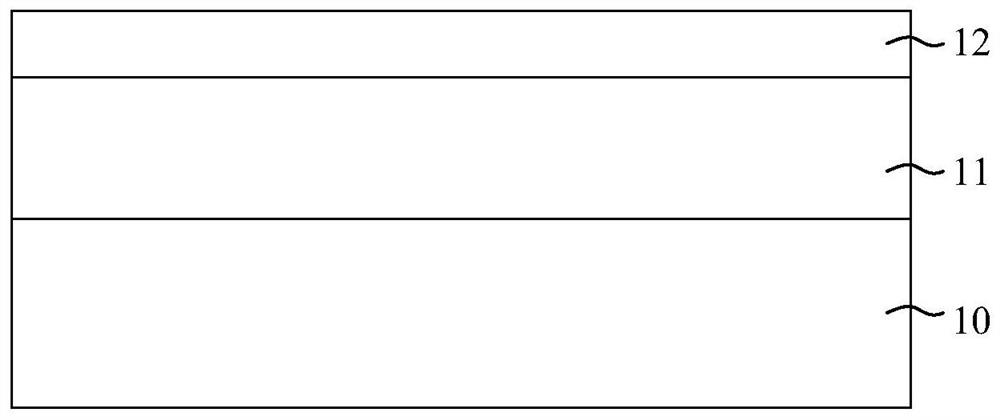

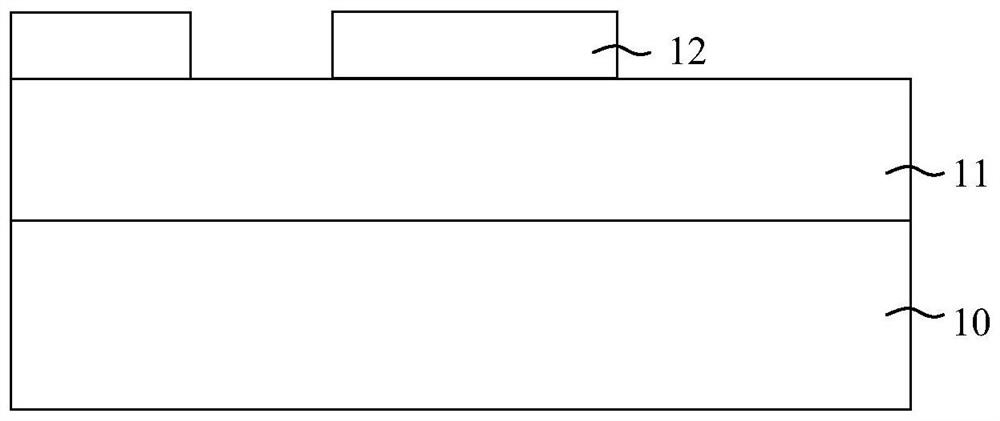

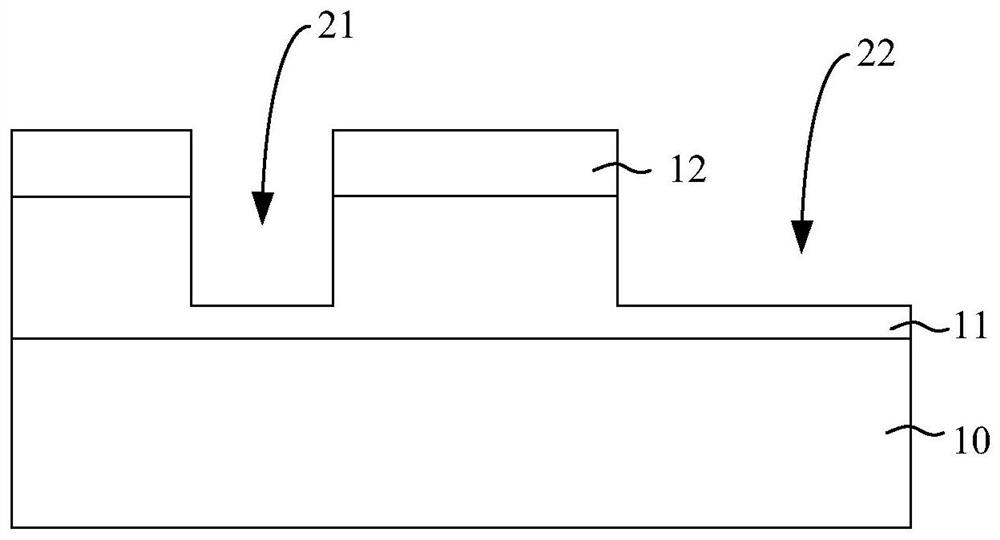

Refrigeration infrared detector and preparation method thereof

PendingCN114256378AStrong adhesionReduce surface leakage currentFinal product manufactureSemiconductor devicesPhysicsIr detector

The invention provides a refrigeration infrared detector and a preparation method thereof, and the preparation method comprises the following steps: providing a substrate, and forming a superlattice composite layer on the substrate; executing a first cleaning and surface treatment process; forming a first passivation layer on the superlattice composite layer; forming a hard mask layer with an opening on the first passivation layer, sequentially etching the first passivation layer and the superlattice composite layer by taking the hard mask layer as a mask to form a groove and a table surface, and removing the hard mask layer; executing a second cleaning and surface treatment process; forming a second passivation layer on the first passivation layer, wherein the second passivation layer also covers the groove and the mesa; and etching the first passivation layer and the second passivation layer to form an open pore, and forming a metal electrode in the open pore. According to the invention, cleaning and surface treatment processes are carried out before the passivation layer is formed each time, so that the surface leakage current of the device can be reduced, and the performance of the device is improved.

Owner:SHANGHAI LEXVU OPTO MICROELECTRONICS TECH

Low-temperature hot melt adhesive, and preparation method and preparation assembly line thereof

PendingCN113214751AGood surface adhesionLow softening temperatureFilm/foil adhesivesSurface bondingWoven fabric

The invention relates to a low-temperature hot melt adhesive, and a preparation method and a preparation assembly line thereof. The low-temperature hot melt adhesive comprises a core layer, one side or two sides of the core layer is / are cooperatively provided with a support layer, and the support layer is externally provided with an adhesive sealing layer. The preparation method comprises the following steps: pre-adjusting equipment, and preparing raw materials; extruding the core layer by using double screws of a screw machine, laminating two preset non-woven fabrics towards the core layer, and integrally outputting to obtain a semi-finished product; cooling, cutting and rolling the output semi-finished product; and taking any cut and rolled semi-finished product, coating two surfaces of the semi-finished product with sealing glue layers to obtain a product, and processing to obtain the finished product. The preparation assembly line of the low-temperature hot melt adhesive comprises the screw machine, one or two sets of conveying rollers are arranged on the two sides of an output port matched with the screw machine, and an ice water unit, a cutting and rolling unit and adhesive sealing layer coating equipment are arranged behind the output port. The hardness of the prepared final product is 57 + / -3 D, the low-temperature deflection resistance can reach 80000 times or more, the surface bonding performance is good, the softening temperature is low, and subsequent processing and use are facilitated.

Owner:HANGZHOU KAIYUE NEW MATERIAL CO LTD

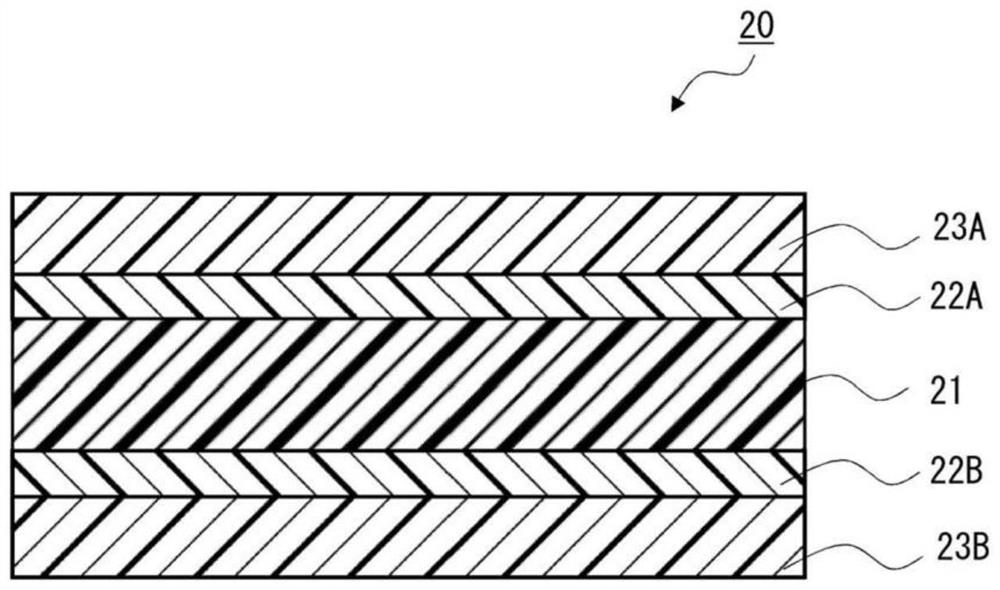

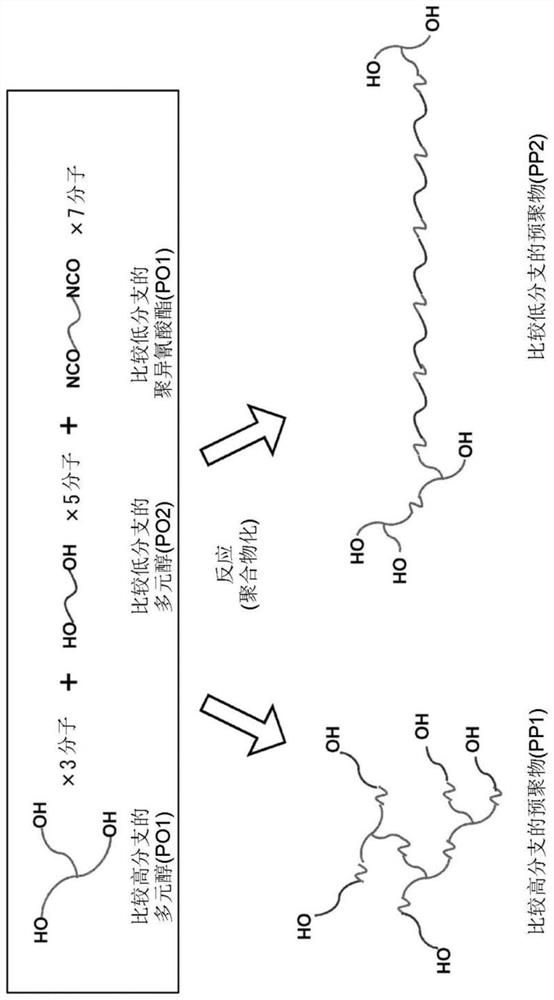

Adhesive and adhesive sheet

PendingCN114206459AGood initial hardeningExcellent peelabilityEntertainmentPolyureas/polyurethane adhesivesPolymer scienceCarbamate

Provided are: an adhesive agent which has good initial hardenability, is capable of forming an adhesive layer that is suppressed in increase in adhesive force even when exposed to a hot environment, particularly a humid and hot environment, and has good removability; and an adhesive sheet which uses the adhesive agent. The adhesive according to the present invention comprises: a hydroxyl-terminated urethane prepolymer (UPH) which is a reaction product of one or more types of active hydrogen group-containing compounds (H) having a plurality of active hydrogen groups in one molecule and one or more types of polyisocyanates (N); and a polyfunctional isocyanate compound (I). The adhesive is a urethane-based adhesive having a branching degree of 0.2 to 0.8 as measured by a GPC-MALS method in a hydroxyl-terminated urethane prepolymer (UPH).

Owner:TOYO INK SC HOLD CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com