Blue-light-resistant coating for trace coating

An anti-blue light and coating technology, applied in the field of coatings, can solve the problems of inability to balance transparency, haze and blue light blocking rate, disadvantageous trace coating cost, cost of anti-blue light protective film, and appearance that does not meet industry standards, etc. Anti-blue light, improved economy and environmental friendliness, less effect of anti-blue light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

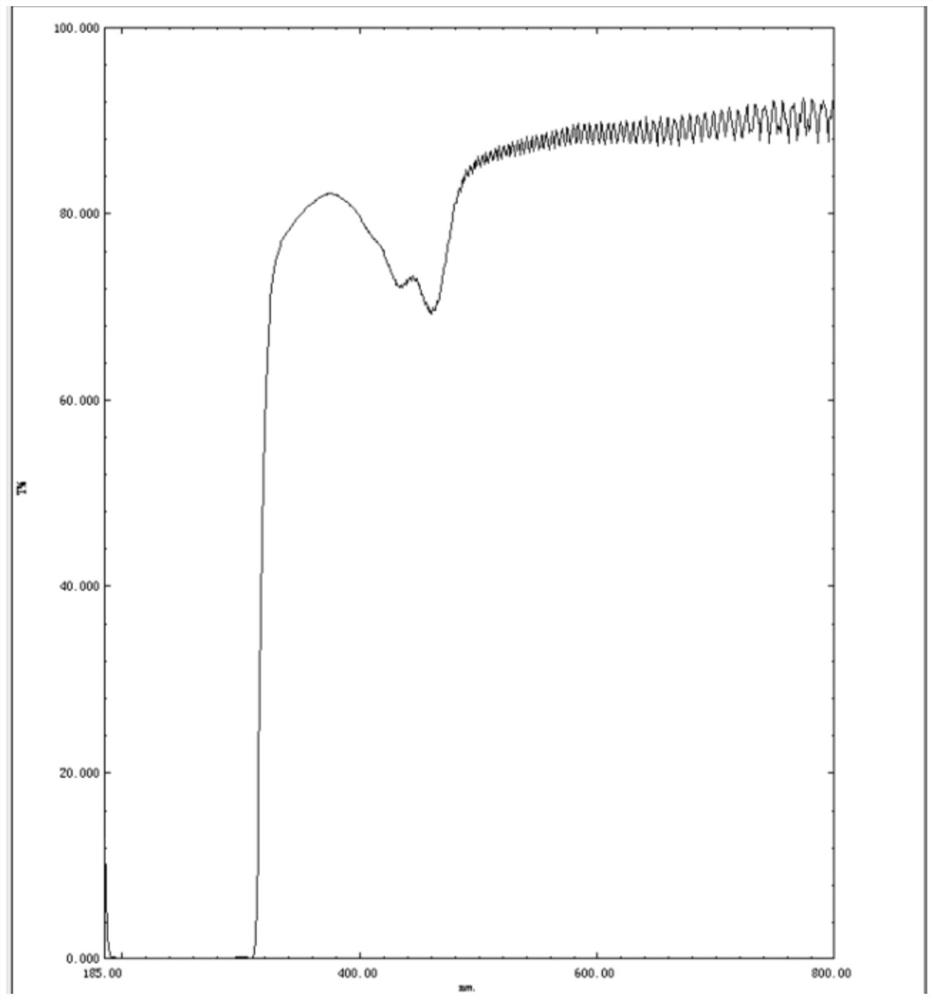

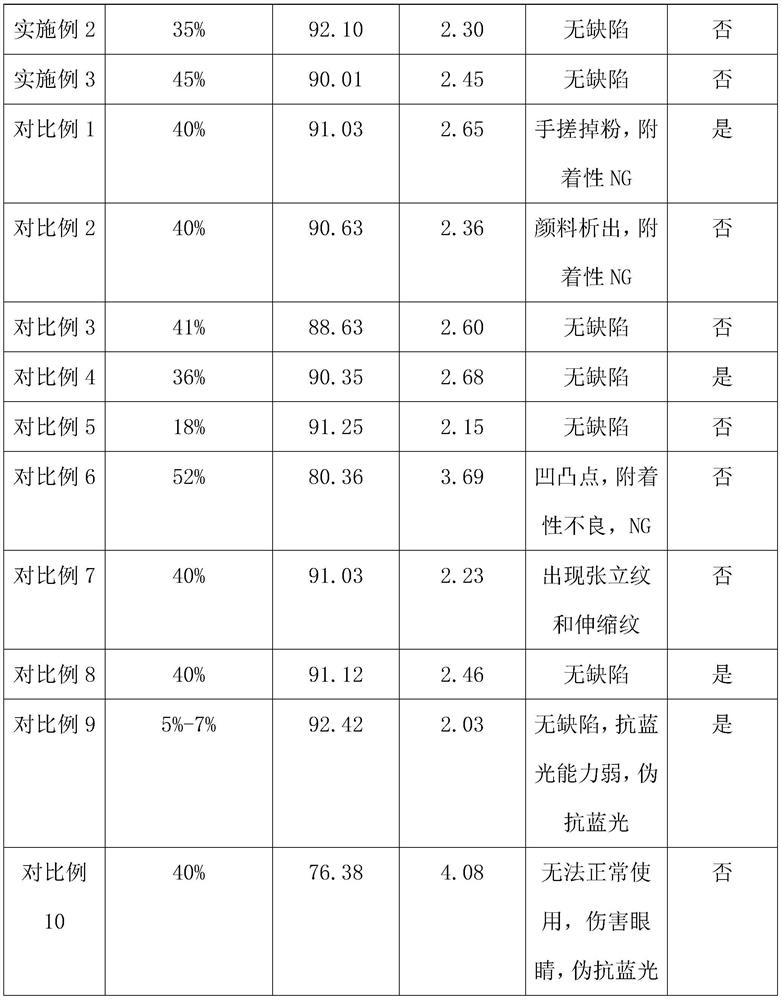

[0025] An anti-blue light coating for micro-coating, including 1g resin, 92g solvent, 0.3g anti-blue light pigment and 0.02g curing agent; wherein, the solvent is xylene, the curing agent is m-PDA, and the anti-blue light pigment is Baichuang The color is NS150, the average particle size of the pigment is 50nm, and the resin is DSM SN805 X-70.

[0026] Prepare the anti-blue light protective film: mix the resin and the solvent, stir evenly, then add the anti-blue light pigment, stir evenly, finally add the curing agent, stir evenly, and obtain the anti-blue light coating; The rod is coated on a PET film with a thickness of 25 μm at a uniform speed, and is cured at a high temperature to form a coating with a thickness of 50 nm to obtain an anti-blue light protective film.

Embodiment 2

[0028] An anti-blue light coating for micro-coating, including 1g resin, 90g solvent, 0.28g anti-blue light pigment and 0.03g curing agent; wherein, the solvent is isopropanol, the curing agent is DETA, and the anti-blue light pigment is Suzhou Sanwei SWN-W-10831, the average particle size of the pigment is 250nm, and the resin is Dow Corning RSN-0217.

[0029] Prepare the anti-blue light protective film: mix the resin and the solvent, stir evenly, then add the anti-blue light pigment, stir evenly, finally add the curing agent, stir evenly, and obtain the anti-blue light coating; The rod is coated on a PET film with a thickness of 25 μm at a uniform speed, and is cured at a high temperature to form a coating with a thickness of 200-250 nm to obtain an anti-blue light protective film.

Embodiment 3

[0031] An anti-blue light coating for micro coating, including 1g resin, 95g solvent, 0.38g anti-blue light pigment and 0.07g curing agent; wherein, the solvent is xylene, the curing agent is m-PDA, and the anti-blue light pigment is Dongfugui Yellow-1, the average particle size of the pigment is 160nm, and the resin is DSM SN805 X-70.

[0032] Prepare the anti-blue light protective film: mix the resin and the solvent, stir evenly, then add the anti-blue light pigment, stir evenly, finally add the curing agent, stir evenly, and obtain the anti-blue light coating; The rod is coated on a PET film with a thickness of 25 μm at a uniform speed, and is cured at a high temperature to form a coating with a thickness of 100-160 nm to obtain an anti-blue light protective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com