Polyformaldehyde product surface processing method

A technology of surface treatment and polyoxymethylene, applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of wastewater treatment and recovery, low adhesion strength, and failure to realize the purpose of the invention, etc., and achieve improvement Surface adhesion performance, prolonging the service life, and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Polyoxymethylene part surface treatment method of the present invention, comprises the following steps:

[0036] a. Use sandblasting to roughen the surface of POM parts and destroy the crystallization area on the surface. The mesh number of sandblasting sand is 45 mesh, and the processing time is 20 seconds; after detection, the thickness of the roughened layer is 570nm-859nm;

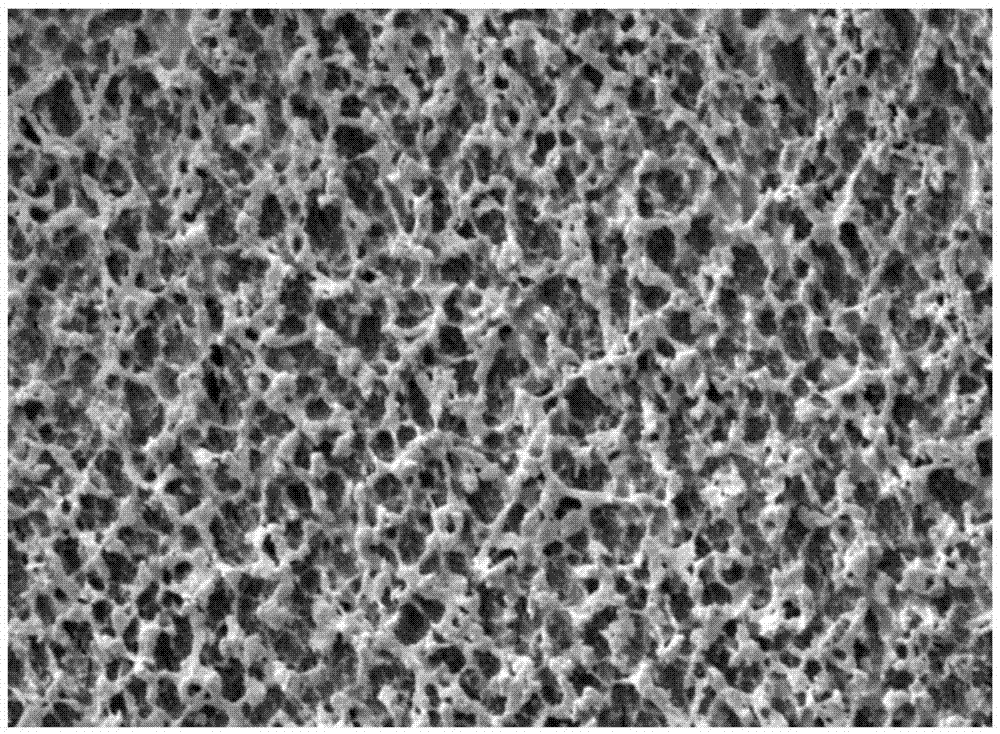

[0037] b. Clean the surface of the roughened polyoxymethylene parts and soak them in acid solution for acid surface treatment. The acid solution is 30% sulfuric acid solution. Soak for 30 minutes at 35°C to form a continuous network of microscopic particles on the surface of the polyoxymethylene parts. Pore structure; the pore diameter of the network microporous structure is 897nm-10um, and the micropore depth is 15um-50um;

[0038] c. After acid surface treatment, rinse with water and dry;

[0039] The paint is amino paint, which is sprayed and cured at 140°C for 40 minutes at high temper...

Embodiment 2

[0041] Polyoxymethylene part surface treatment method of the present invention, comprises the following steps:

[0042]a. Use sandblasting to roughen the surface of POM parts and destroy the crystallization area on the surface. The mesh number of sandblasting sand is 80 mesh, and the processing time is 20 seconds; after testing, the thickness of the roughened layer is 715nm-150um;

[0043] b. Clean the surface of the roughened polyoxymethylene part and then soak it in acid solution for acid surface treatment. The acid solution is 30% hydrochloric acid solution. Soak it for 30 minutes at 50°C to form a continuous network of microscopic particles on the surface of the polyoxymethylene part. Pore structure; the pore diameter of the network microporous structure is 565nm-995nm, and the micropore depth is 995nm-17um;

[0044] c. After acid surface treatment, rinse with water and dry;

[0045] The paint is amino paint, which is sprayed and cured at 140°C for 40 minutes at high...

Embodiment 3

[0047] Polyoxymethylene part surface treatment method of the present invention, comprises the following steps:

[0048] a. Use sandblasting to roughen the surface of POM parts and destroy the crystallization area on the surface. The mesh number of sandblasting sand is 45 mesh, and the processing time is 10 seconds; after detection, the thickness of the roughened layer is 550nm-795nm;

[0049] b. Clean the surface of the roughened polyoxymethylene parts and soak them in acid solution for acid surface treatment. The acid solution is 15% hydrochloric acid solution. Soak for 30 minutes at 30°C to form a continuous network of microscopic particles on the surface of the polyoxymethylene parts. Pore structure; the pore diameter of the network microporous structure is 320nm-798nm, and the micropore depth is 685nm-955nm;

[0050] c. After acid surface treatment, rinse with water and dry;

[0051] The paint is amino paint, which is sprayed and cured at 140°C for 40 minutes at high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com