Refrigeration infrared detector and preparation method thereof

A technology of infrared detectors and passivation layers, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as unstable detection rate and failure to meet design requirements, and achieve reduced surface leakage current, Improve the ohmic contact and increase the effect of surface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the current cooling infrared detector comprises the following steps:

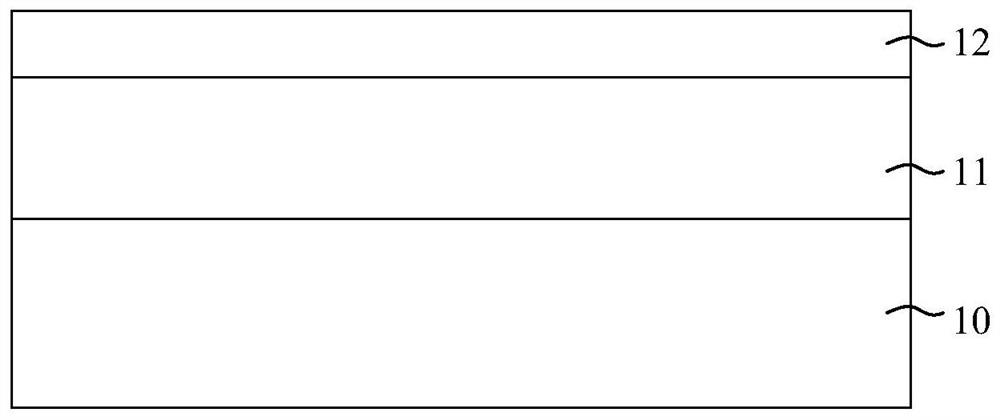

[0044] like Figure 1a As shown, step S11: providing a substrate 10, on which a superlattice composite layer 11 and a hard mask layer 12 are sequentially formed;

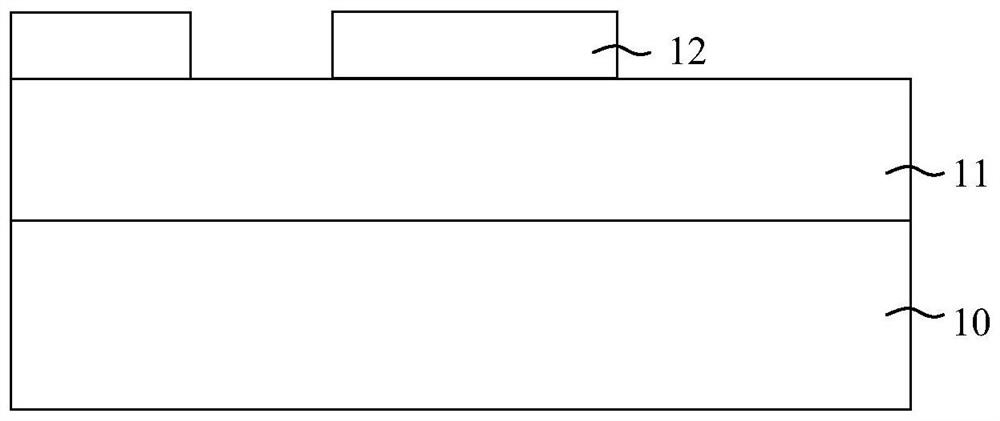

[0045] like Figure 1b As shown, step S12: etching the hard mask layer 12, and exposing part of the surface of the superlattice composite layer 11;

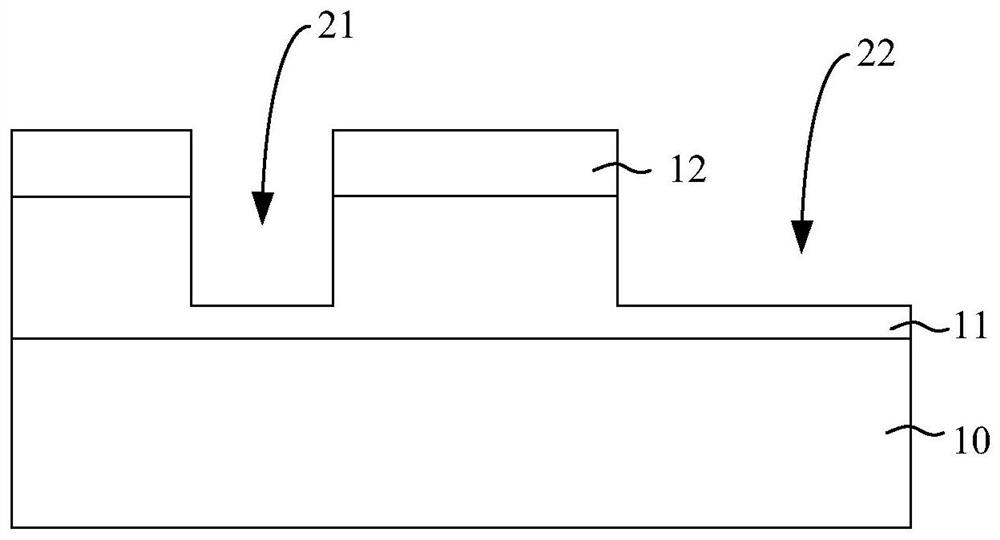

[0046] like Figure 1c As shown, step S13: using the hard mask layer 12 as a mask, etch part of the depth of the superlattice composite layer 11 to form trenches 21 and mesas 22;

[0047] like Figure 1d As shown, step S14: remove the remaining hard mask layer 12;

[0048] like Figure 1e As shown, step S15: form a passivation film layer 30 on the surface of the superlattice composite layer 11 once, and the passivation film layer 30 covers the inner wall of the groove 21 and the surface of the mesa 22;

[0049] like Figure 1f As shown, step S16: etching the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com