Preparation method of suspended packing bioreactor and application thereof

A technology of biological filler and reclaimed rubber powder, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of unfavorable mass production, complex structure design, increased production cost, etc., and achieve shortening The film-hanging cycle, the effect of improving the treatment effect, and the effect of fast film-hanging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The magnetic powder, reclaimed rubber powder, zeolite, maleic anhydride, dicumyl peroxide, chitin, coke powder, and slag powder are crushed and passed through a 200-mesh sieve. Weigh 0.2kg of ferroferric oxide magnetic powder, 8kg of reclaimed rubber powder, 8kg of zeolite, 3kg of maleic anhydride, 0.5kg of dicumyl peroxide, 1.5kg of chitin, 5kg of coke powder, and 2kg of slag powder in a high-speed mixer Mix well, then add 75kg of high-density polyethylene and stir at high speed. Add the mixture into the silo of the twin-screw granulator, and complete the granulation process through the twin-screw granulator. After granulation, the granules are added to the silo of the twin-screw extruder, through heating, moulding, vacuum setting, cooling, and mechanical opening (the opening machine is a rolling high-temperature probe, the pillow temperature is greater than 250°C, and the needle size is 200nm) , cutting. Finally, the filler was irradiated with ultraviolet light with...

Embodiment 2

[0028] The magnetic powder, reclaimed rubber powder, zeolite, maleic anhydride, dicumyl peroxide, chitin, coke powder, and slag powder are crushed and passed through a 200-mesh sieve, wherein the magnetic powder is trioxide tetroxide with a mass ratio of 9:1 Ferromagnetic powder and manganese zinc ferrite mixture. Weigh 0.6kg of magnetic powder, 8kg of reclaimed rubber powder, 8kg of zeolite, 3kg of maleic anhydride, 0.5kg of dicumyl peroxide, 1.5kg of chitin, 5kg of coke powder, and 2kg of slag powder, and place them in a high-speed mixer to fully mix them , and then add 70kg of high-density polyethylene and mix well. Add the mixture into the silo of the twin-screw granulator, and complete the granulation process through the twin-screw granulator. After granulation, the granules are added to the silo of the twin-screw extruder, through heating, moulding, vacuum setting, cooling, and mechanical opening (the opening machine is a rolling high-temperature probe, the pillow tempe...

Embodiment 3

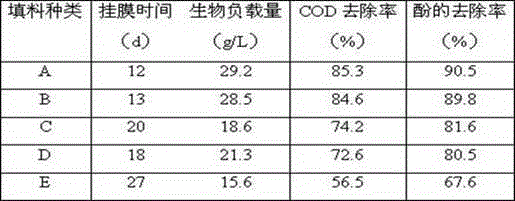

[0036]Get the same amount of products A, B, C, D, and E obtained in Examples 1-2 and Comparative Examples 1-3 and soak them in water for 4 hours, then take them out and let them stand for 30 minutes to measure their moisture content. The moisture contents of products A, B, C, D, and E are 18.5, 19.2, 14.7, 14.4, and 9.6, respectively. The contact angles of products A, B, C, D, and E were measured and calculated with a contact angle measuring instrument, and they were 62°, 60°, 75°, 72°, and 81°, respectively. The results show that the hydrophilic property of the suspended biological filler prepared by the present invention is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com