Anti-fog coating, preparation method thereof and anti-fog glass

An anti-fog coating and anti-fog glass technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of cumbersome two-layer coating process, increase production costs, etc., achieve good anti-fog effect, reduce production costs, and simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation raw material of described hydrophilic copolymer comprises:

[0058] Hydrophilic monomer, initiator and second solvent;

[0059] The solubility of the epoxy resin in water is greater than or equal to 90%;

[0060] The solubility of the hydrophilic copolymer in water is greater than or equal to 90%.

[0061] The invention utilizes the polymerization reaction of the hydrophilic monomer under the action of the initiator to prepare the hydrophilic copolymer with high solubility. Then the hydrophilic copolymer and epoxy resin with high solubility react under the action of curing agent. Wherein, the hydrophilic copolymer is a linear polymer, and the hydrophilic copolymer of linear structure can be cross-linked with epoxy resin to form a firm semi-interpenetrating network structure, which is conducive to improving surface adhesion, wear resistance, toughness and durability. hot sex. The semi-interpenetrating network structure can release the stress generated...

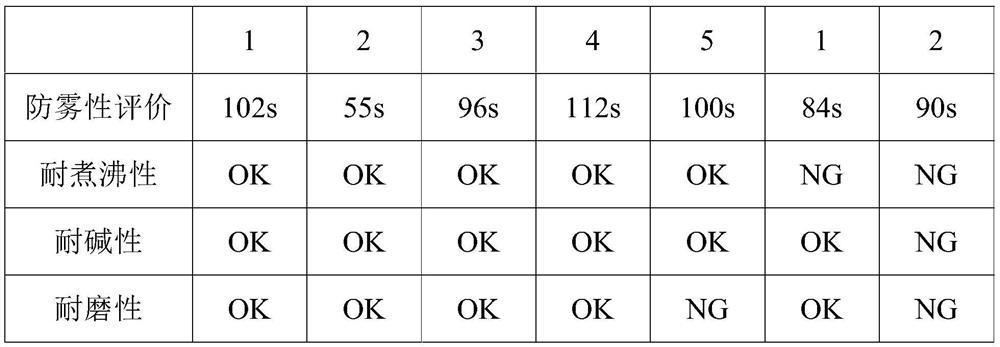

Embodiment 1

[0119] This embodiment provides an anti-fog glass and a preparation method thereof. Proceed as follows:

[0120] Step 1: Preparation of Hydrophilic Copolymer

[0121] Weigh 2g of hydroxyethyl acrylate, 4g of acrylamide, and 40g of propylene glycol methyl ether into the reaction flask, pass through nitrogen protection, stir well, then add 0.15g of azobisisobutylcyanide, and place the reaction flask in a 70°C oil bath , stirred and reacted for 12 hours to obtain a hydrophilic copolymer with a solubility of 94%.

[0122] Step 2: Prepare anti-fog coating

[0123] Get 7.5g of the hydrophilic copolymer prepared in step 1, 5g of epoxy resin EX-313 (a commercial product of Nagase Chemtex Corporation in Japan, belonging to glycerol triglycidyl ether, with a solubility of 99%), and the mass ratio of the two is 1.5:1 , uniformly mix the two in 50 g of absolute ethanol, then add 0.5 g of silane coupling agent KH550 and 0.6 g of diethylenetriamine, stir evenly, and react at room tempera...

Embodiment 2

[0127] This embodiment provides an anti-fog glass and a preparation method thereof. Proceed as follows:

[0128] Step 1: Preparation of Hydrophilic Copolymer

[0129] Weigh 2g of hydroxyethyl acrylate, 4g of acrylamide, and 40g of propylene glycol methyl ether into the reaction flask, pass through nitrogen protection, stir well, then add 0.15g of azobisisobutylcyanide, and place the reaction flask in a 70°C oil bath , stirred and reacted for 12 hours to obtain a hydrophilic copolymer with a solubility of 94%.

[0130] Step 2: Prepare anti-fog coating

[0131] Get the hydrophilic copolymer prepared by 12g step 1, 3g epoxy resin EX-614B (the Japanese Nagase Chemtex Corporation commercial product, belong to sorbitol glycidyl ether, solubility is 94%), the mass ratio of the two is 4:1, will The two were uniformly mixed in 50 g of absolute ethanol, then 0.5 g of silane coupling agent KH560 and 0.4 g of diethylenetriamine were added, stirred evenly, and reacted at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com