Breathable textile fabric and preparation method thereof

A technology of textile fabrics and air permeability, applied in the field of breathable textile fabrics and its preparation, can solve the problems of large odor, poor air permeability, etc., and achieve the effect of improving service life, prolonging service life and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

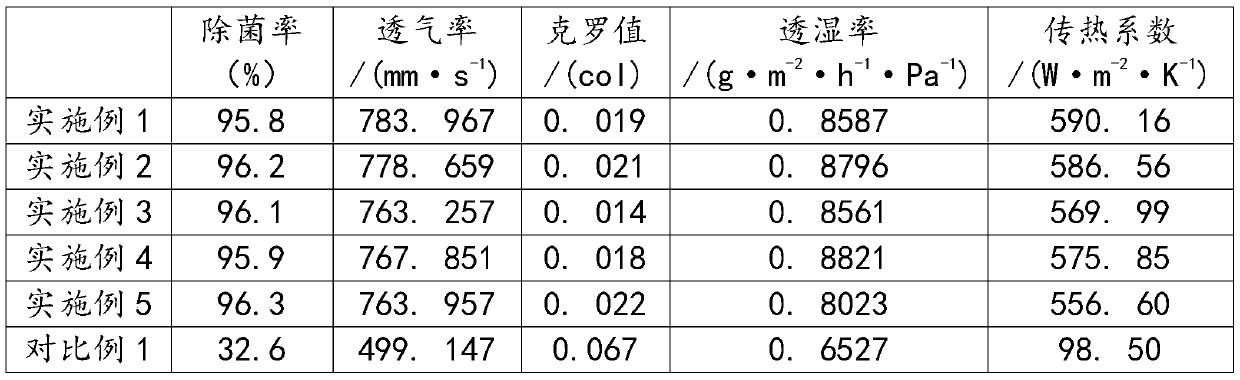

Examples

Embodiment 1

[0045] This embodiment relates to a kind of breathable textile fabric, wherein, antibacterial warp raw silk comprises water-absorbing fiber 4kg, jute fiber 3kg, silk fiber 2kg, antibacterial coating 2kg, and weft yarn raw silk comprises superfine activated carbon fiber 5kg, polyester fiber 4kg, 3kg of aramid fibers and 1kg of ramie fibers, the second warp yarn precursors include 3kg of carbon nanofibers, 3kg of bamboo charcoal fibers, and 2kg of 15D polyester staple fibers.

[0046] Among them, the antibacterial coating is made by mixing 4kg of Fe-MOF nanomaterials, 5kg of glycerin, 4kg of sodium polymethacrylate, 3kg of polyhexamethyleneguanidine hydrochloride, 2kg of nano ZSM-5 molecular sieves, and 2kg of earthworm antimicrobial peptides.

[0047] The breathable textile fabric of this embodiment is prepared according to the following steps:

[0048] S1. Production of antibacterial warp yarn raw silk: mix water-absorbent fiber, jute fiber, silk fiber, and distilled water and...

Embodiment 2

[0053] This embodiment relates to a kind of breathable textile fabric, wherein, antibacterial warp raw silk comprises water-absorbing fiber 10kg, jute fiber 9kg, silk fiber 4kg, antibacterial coating 4kg, and weft yarn raw silk comprises superfine activated carbon fiber 12kg, polyester fiber 12kg, 9kg of aramid fibers and 3kg of ramie fibers, the second warp yarn precursors include 9kg of carbon nanofibers, 8kg of bamboo charcoal fibers, and 6kg of 15D polyester staple fibers.

[0054] Among them, the antibacterial coating is made by mixing 10kg of Fe-MOF nanomaterials, 15kg of glycerin, 12kg of sodium polymethacrylate, 9kg of polyhexamethyleneguanidine hydrochloride, 6kg of nano ZSM-5 molecular sieves, and 4kg of earthworm antimicrobial peptides.

[0055] The breathable textile fabric of this embodiment is prepared according to the following steps:

[0056] S1. Production of antibacterial warp yarn raw silk: mix water-absorbent fiber, jute fiber, silk fiber, and distilled water...

Embodiment 3

[0061] This embodiment relates to a kind of breathable textile fabric, wherein, antibacterial warp raw silk comprises water-absorbing fiber 5kg, jute fiber 4kg, silk fiber 3kg, antibacterial coating 2kg, and weft yarn raw silk comprises superfine activated carbon fiber 6kg, polyester fiber 5kg, 4kg of aramid fibers and 2kg of ramie fibers, the second warp yarn precursors include 4kg of carbon nanofibers, 4kg of bamboo charcoal fibers, and 3kg of 15D polyester staple fibers.

[0062] Among them, the antibacterial coating is made by mixing 4kg of Fe-MOF nanomaterials, 13kg of glycerin, 5kg of sodium polymethacrylate, 4kg of polyhexamethyleneguanidine hydrochloride, 5kg of nano ZSM-5 molecular sieves, and 2kg of earthworm antimicrobial peptides.

[0063] The breathable textile fabric of this embodiment is prepared according to the following steps:

[0064] S1. Production of antibacterial warp yarn raw silk: mix water-absorbent fiber, jute fiber, silk fiber, and distilled water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com