Hydrogenated active cathode and preparation method thereof and electrolytic tank with hydrogenated active cathode

An active cathode and hydrogen evolution technology, applied in the field of electrochemistry, can solve the problems of chlorine damage and low hydrogen evolution potential, and achieve the effects of preventing heavy metal pollution, low hydrogen evolution potential and excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The method for preparing the hydrogen evolution active cathode provided by the present invention comprises the following steps:

[0039] (1) Provide a conductive substrate;

[0040] (2) Provide the solution of nitrate metal salt, described nitrate metal salt comprises the mixture of noble metal nitrate and lanthanide metal nitrate, wherein in the mixture, described noble metal nitrate and described lanthanide metal nitrate The molar percentage of salt is 75%: 25%-85%: 15%;

[0041] (3) coating the conductive substrate with the solution of the nitrate metal salt to obtain a coated conductive substrate, without performing an air-fired treatment before the coating; and

[0042] (4) heat treating the coated conductive substrate to obtain an active catalyst coating on the conductive substrate.

[0043] Wherein, the conductive substrate is not particularly limited, and it can be any conductive substrate available in the art, especially a nickel conductive substrate or a nic...

Embodiment 1

[0059] The hydrogen evolution active cathode of this embodiment and its preparation method are as follows:

[0060] ⑴ Pretreatment of nickel substrate

[0061] First use 320-mesh white corundum sand to sandblast the nickel substrate, then prepare a sulfuric acid solution with a mass fraction of 25%, heat it up to 30°C and put it into the nickel substrate, soak and corrode the nickel substrate to reduce the weight of the nickel substrate It reaches 0.6±0.1% of the total weight of the net. After the corrosion is finished, rinse the nickel substrate with clean water to remove the residual acid corrosion solution on the surface.

[0062] ⑵Preparation of nitric acid metal salt solution

[0063] This embodiment contains ruthenium nitrate and cerium nitrate, wherein the concentration of ruthenium nitrate is 100 g / L, and the molar percentage of metal salt is ruthenium:cerium=85%:15%.

[0064] Put the ruthenium nitrate solution on a magnetic stirrer with a heater and stir for 10 minu...

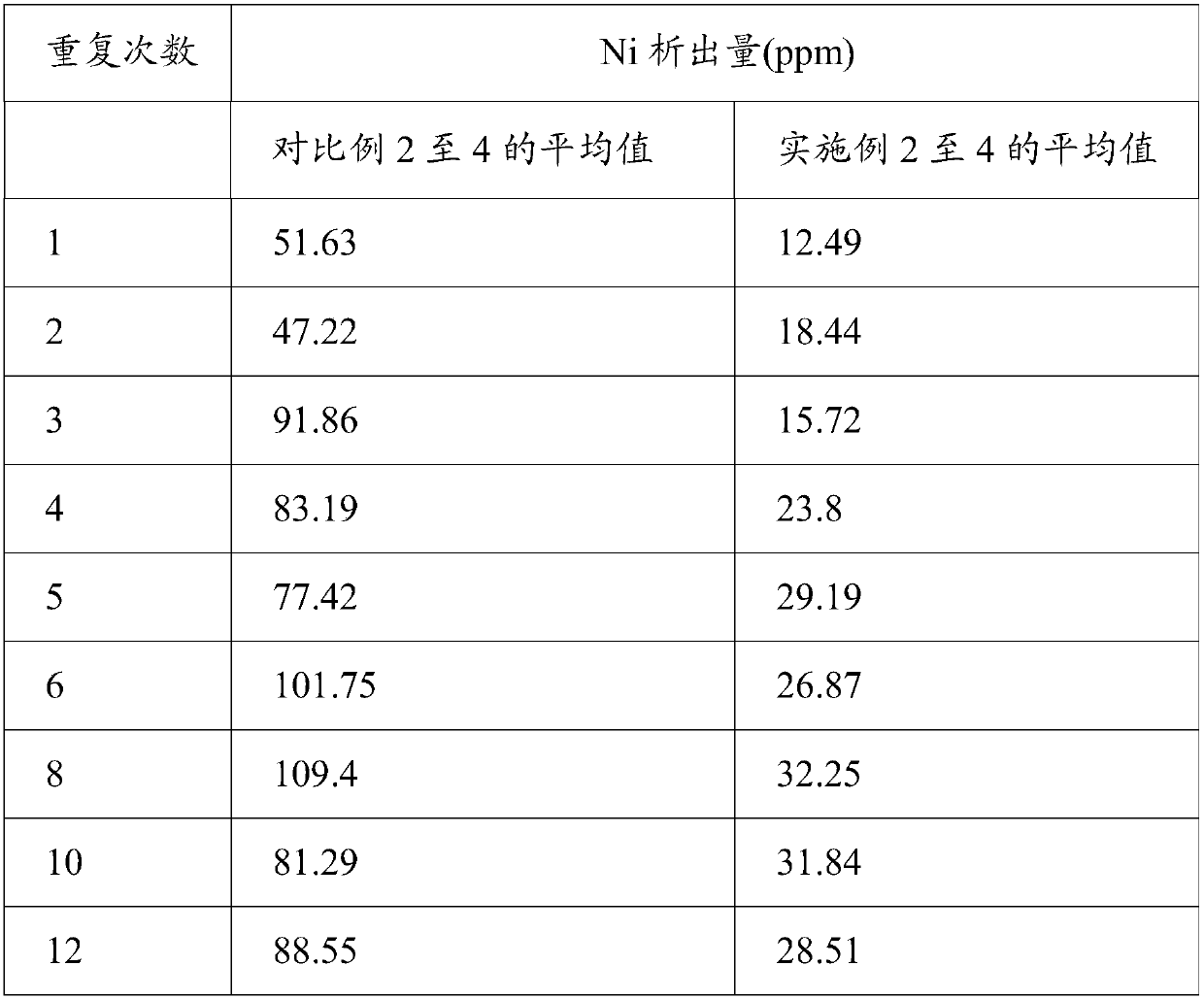

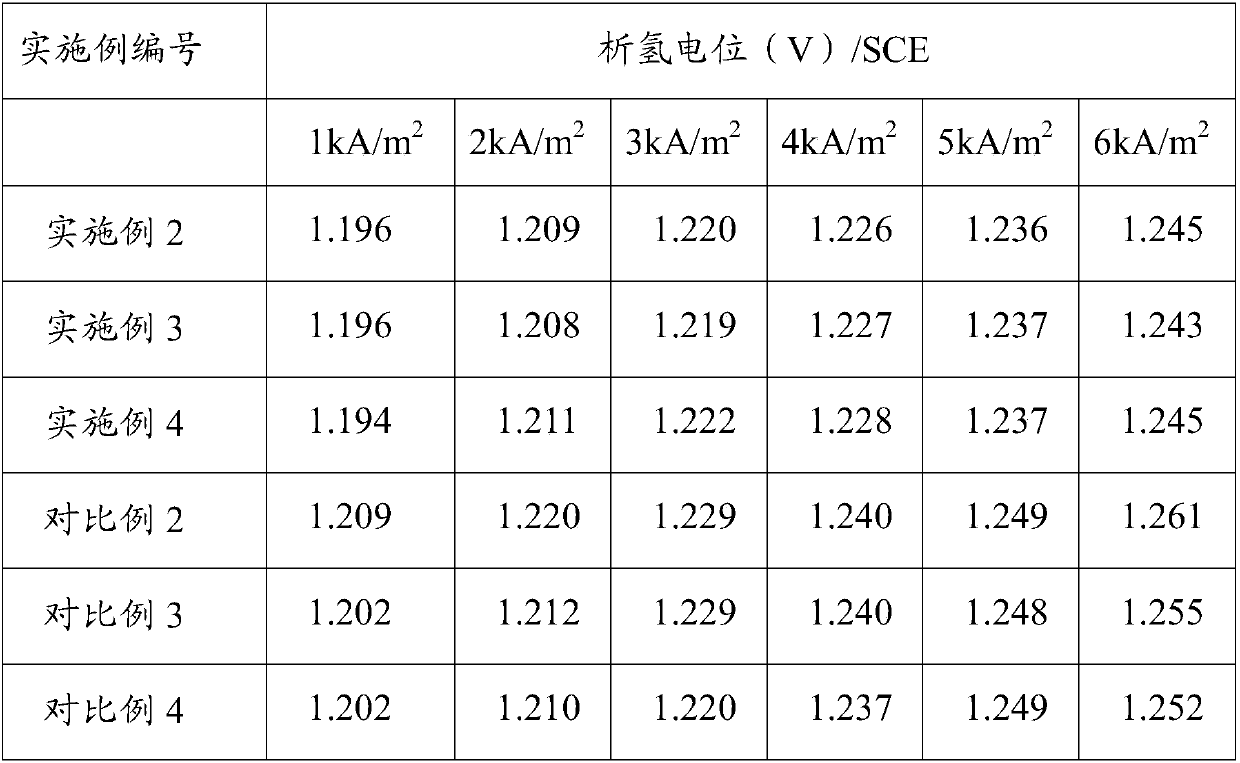

Embodiment 2

[0068] The hydrogen evolution active cathode of this embodiment and its preparation method are as follows:

[0069] ⑴ Pretreatment of nickel substrate

[0070] First use 320-mesh white corundum sand to sandblast the nickel substrate, then prepare a sulfuric acid solution with a mass fraction of 30%, heat up to 50°C and put it into the nickel substrate, soak and corrode the nickel substrate to reduce the weight of the nickel substrate Reach 0.6±0.1% of the total weight of the net. After the corrosion is finished, rinse the nickel substrate with clean water to remove the residual acid corrosion solution on the surface.

[0071] ⑵Preparation of nitric acid metal salt solution

[0072] This embodiment contains ruthenium nitrate and cerium nitrate, wherein the concentration of ruthenium nitrate is 100 g / L, and the molar percentage of metal salt is ruthenium:cerium=85%:15%.

[0073] Put the ruthenium nitrate solution on a magnetic stirrer with a heater and stir for 10 minutes, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com