Method for preparing nanometer iron-loaded amine-modified bio-char and application thereof

An amino-modified, biological carbon technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of improving surface characteristics and stability, improving surface properties, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

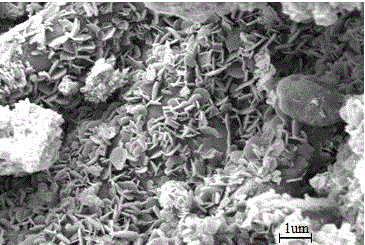

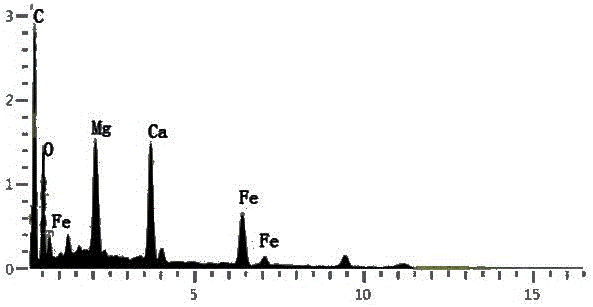

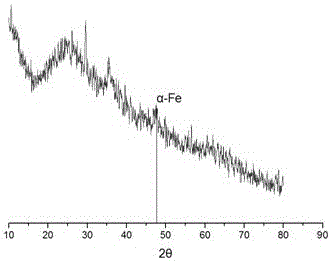

[0029] Nano-iron-loaded amino-modified biochar, its preparation and application process are as follows:

[0030] (1) Freeze-dry 2 kg of water hyacinth bulbs, crush them, put them in a tube furnace, pass nitrogen gas for 10 minutes, flow rate is 0.5L / min, and rapidly raise the temperature, and keep constant temperature for 5 hours after reaching 350°C to obtain water hyacinth biochar;

[0031] (2) Take 10g of water hyacinth biochar and place it in 1mol / L dilute hydrochloric acid, stir at constant temperature to remove ash, and filter to obtain a solid; take 5g of solid, add a mixed solution of 50ml concentrated sulfuric acid and 50ml concentrated nitric acid in a volume ratio, and then mechanically stir the reaction 4 hour, suction filtration, cleaning and drying;

[0032] (3) Add the dried product in step (2) to 15 mL of ammonia water, mechanically stir for 15 minutes, add 25 g of sodium dithionite, stir at a constant speed for 24 hours, filter, wash and dry to obtain amino-mo...

Embodiment 2

[0036] The preparation and application process of nano-iron loaded amino-modified bio-carbon is as follows:

[0037] (1) 4 kg of water hyacinth bulbs were freeze-dried and pulverized, placed in a tube furnace, fed with nitrogen for 15 minutes, with a flow rate of 0.7 L / min, and rapidly heated up to 375°C and kept at a constant temperature for 5.5 hours to obtain water hyacinth biochar;

[0038] (2) Take 10g of water hyacinth biochar and place it in 0.5mol / L dilute hydrochloric acid, stir at constant temperature to remove ash, and filter to obtain a solid; take 5g of solid, add a mixed solution of 50ml concentrated sulfuric acid and 60ml concentrated nitric acid in a volume ratio, and then mechanically stir the reaction 4 hours, suction filtration, cleaning and drying;

[0039] (3) Add the dried product in step (2) to 18 mL of ammonia water, stir mechanically for 30 minutes, add 28 g of sodium dithionite, stir at a constant speed for 24 hours, filter, wash and dry to obtain ami...

Embodiment 3

[0043] The preparation and application process of nano-iron loaded amino-modified bio-carbon is as follows:

[0044] (1) 6 kg of water hyacinth bulbs were freeze-dried and pulverized, placed in a tube furnace, ventilated with nitrogen for 20 minutes, with a flow rate of 0.8 L / min, and rapidly raised the temperature to 400°C and kept at a constant temperature for 6 hours to obtain water hyacinth biochar;

[0045] (2) Take 10g of water hyacinth biochar and place it in 0.8mol / L dilute hydrochloric acid, stir at constant temperature to remove ash, and filter to obtain a solid; take 5g of solid, add a mixed solution of 50ml concentrated sulfuric acid and 55ml concentrated nitric acid in a volume ratio, and then mechanically stir the reaction 4 hours, suction filtration, cleaning and drying;

[0046] (3) Add the dried product in step (2) to 20 mL of ammonia water, mechanically stir for 40 minutes, add 30 g of sodium dithionite, stir at a constant speed for 24 hours, filter, wash and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com