Preparation method of water-based flame-retardant grey gum type back glue PVC

A technology of grey glue and back glue, applied in the direction of adhesive, adhesive type, film/flake adhesive, etc., can solve the problems of poor glue performance, easy burning, excessive glue residue, etc., and achieve good anti-oxidation performance , High color reproduction, good surface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

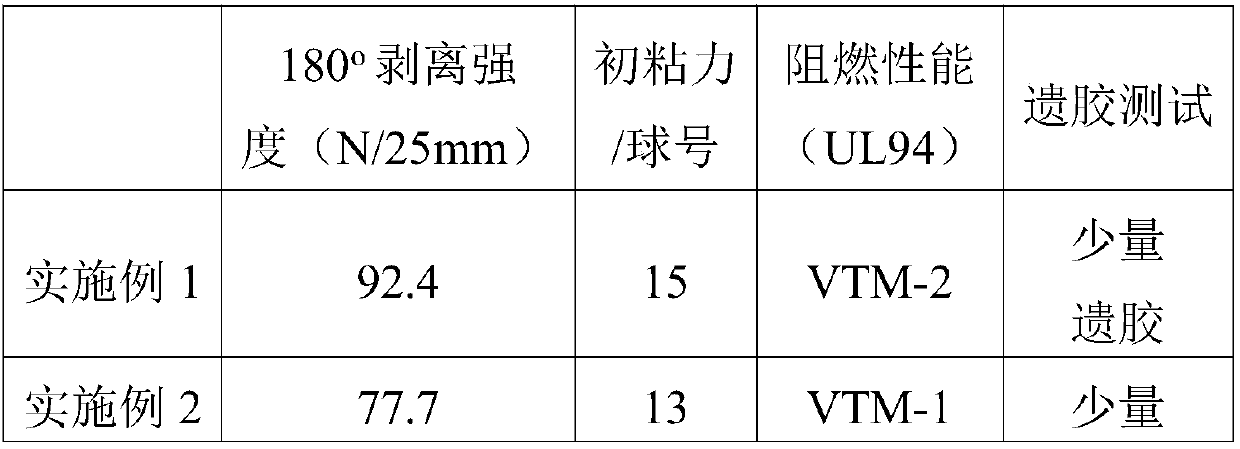

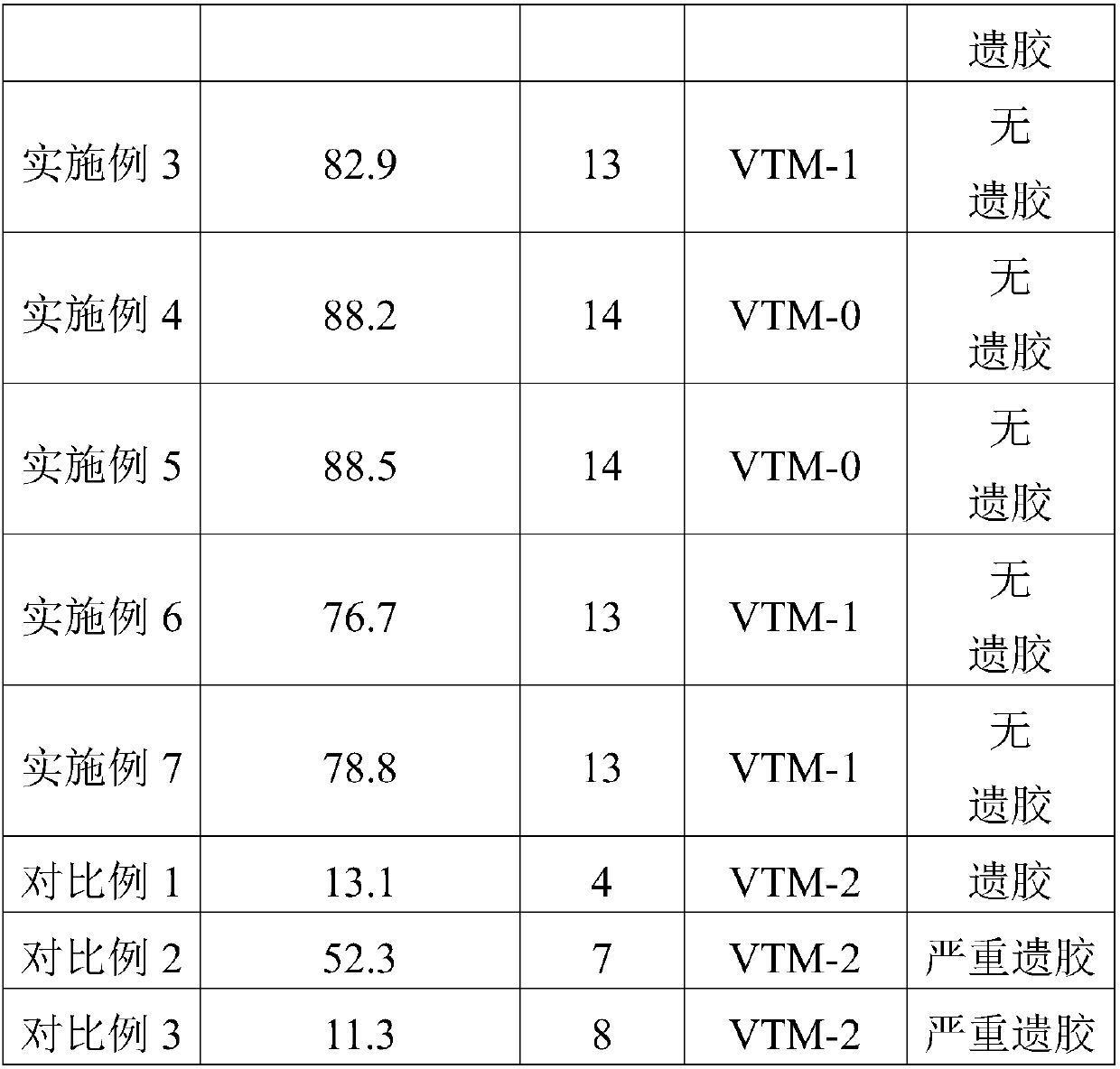

Examples

Embodiment 1

[0034] In terms of weight percentage, weigh the following components:

[0035] (1) Flame retardant coating: in 89.9% polyvinyl alcohol solution, add 3.5% aluminum hydroxide, 3% ammonium polyphosphate, 3.5% melamine and 0.1% wetting agent and mix well;

[0036] (2) Special flame retardant mortar: 54% butyl acrylate, 8% methyl methacrylate, 4% acrylic acid, 4% acryl alcohol, 14.9% 2-ethyl (methacryloxymethyl) phosphate , melamine 3%, gray paste 4%; sodium lauryl sulfate 0.1%, mix well, then add initiator 2%, react at 70-90°C for 7-9h, then add latex powder 1%, nano attapulgite 2 %Continue to react for 1-3 hours; after cooling to normal temperature, add 3% curing agent, stir for 20-40 minutes, filter, and set aside;

[0037] (3) Coating flame retardant coating 15-30g / m on the white PVC layer 2 , after drying; Coat the other side of the white PVC layer with special flame-retardant gray glue 15-30g / m 2 , the coating speed is 20-40m / min, after drying, after laminating with the re...

Embodiment 2

[0039] In terms of weight percentage, weigh the following components:

[0040] (1) Flame retardant coating: add 10% aluminum hydroxide, 10% ammonium polyphosphate, 10% melamine and 0.5% wetting agent to 69.5% polyvinyl alcohol solution and mix evenly;

[0041] (2) Special flame retardant mortar: 40% butyl acrylate, 4% methyl methacrylate, 2% acrylic acid, 2% acrylic alcohol, 13.7% 2-ethyl (methacrylic acid acyloxymethyl) phosphate , melamine 8%, gray paste 10%; sodium lauryl sulfate 0.3%, mix well, then add initiator 4%, react at 70-90°C for 7-9h, then add latex powder 5%, nano attapulgite 6 %Continue to react for 1-3 hours; after cooling to normal temperature, add 5% curing agent, stir for 20-40 minutes, filter, and set aside;

[0042] (3) Coating flame retardant coating 15-30g / m on the white PVC layer 2 , after drying; Coat the other side of the white PVC layer with special flame-retardant gray glue 15-30g / m 2 , the coating speed is 20-40m / min, after drying, after laminat...

Embodiment 3

[0044] In terms of weight percentage, weigh the following components:

[0045](1) Flame retardant coating: add 7% aluminum hydroxide, 6.5% ammonium polyphosphate, 6.5% melamine and 0.3% wetting agent to 79.7% polyvinyl alcohol solution and mix evenly;

[0046] (2) Special flame retardant mortar: 48% butyl acrylate, 6% methyl methacrylate, 3% acrylic acid, 3% acrylic alcohol, 13.5% 2-ethyl (methacrylic acid acyloxymethyl) phosphate , melamine 5%, gray paste 7%, sodium lauryl sulfate 0.2%, mix well, then add initiator 3%, react at 70-90°C for 7-9h, then add latex powder 3%, nano attapulgite 4 %Continue to react for 1-3 hours; after cooling to normal temperature, add 4.3% curing agent, stir for 20-40 minutes, filter, and set aside;

[0047] (3) Coating flame retardant coating 15-30g / m on the white PVC layer 2 , after drying; Coat the other side of the white PVC layer with special flame-retardant gray glue 15-30g / m 2 , the coating speed is 20-40m / min, after drying, after lamina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com