Preparation method of inorganic and organic composite coating diaphragm

An organic and diaphragm technology, applied in electrical components, circuits, battery pack parts, etc., can solve the problems of low peel resistance with the diaphragm surface, peeling off of the slurry coating, difficult curing, etc., to achieve excellent heat resistance, coating The effect of convenient cloth and good mechanical tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

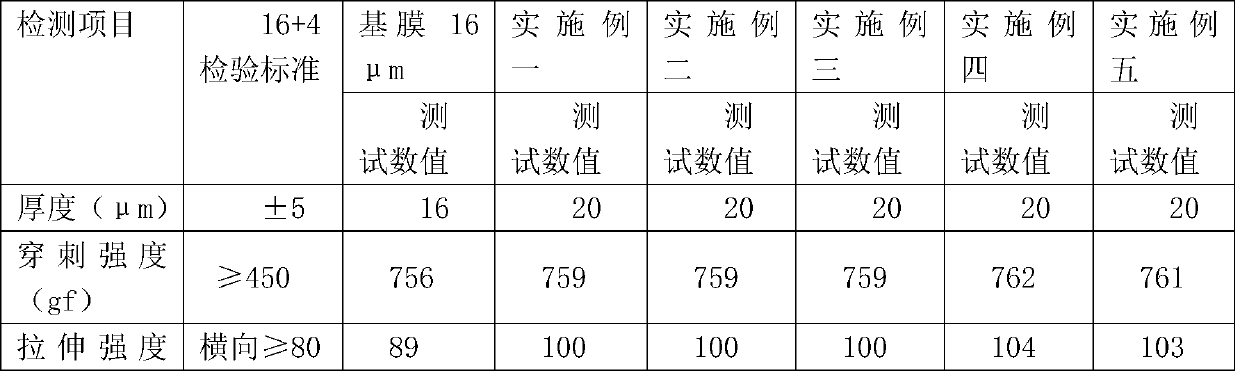

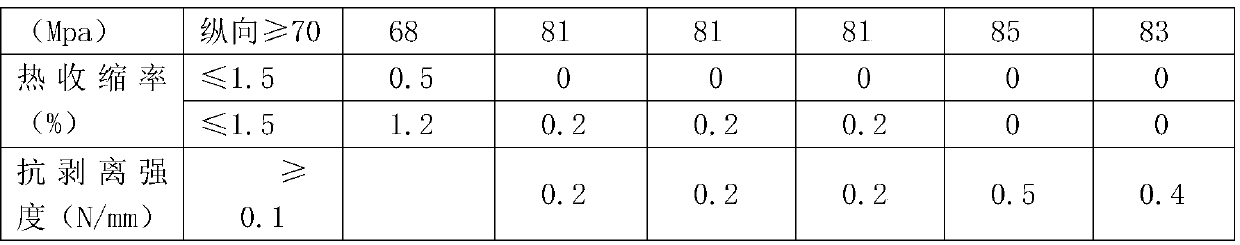

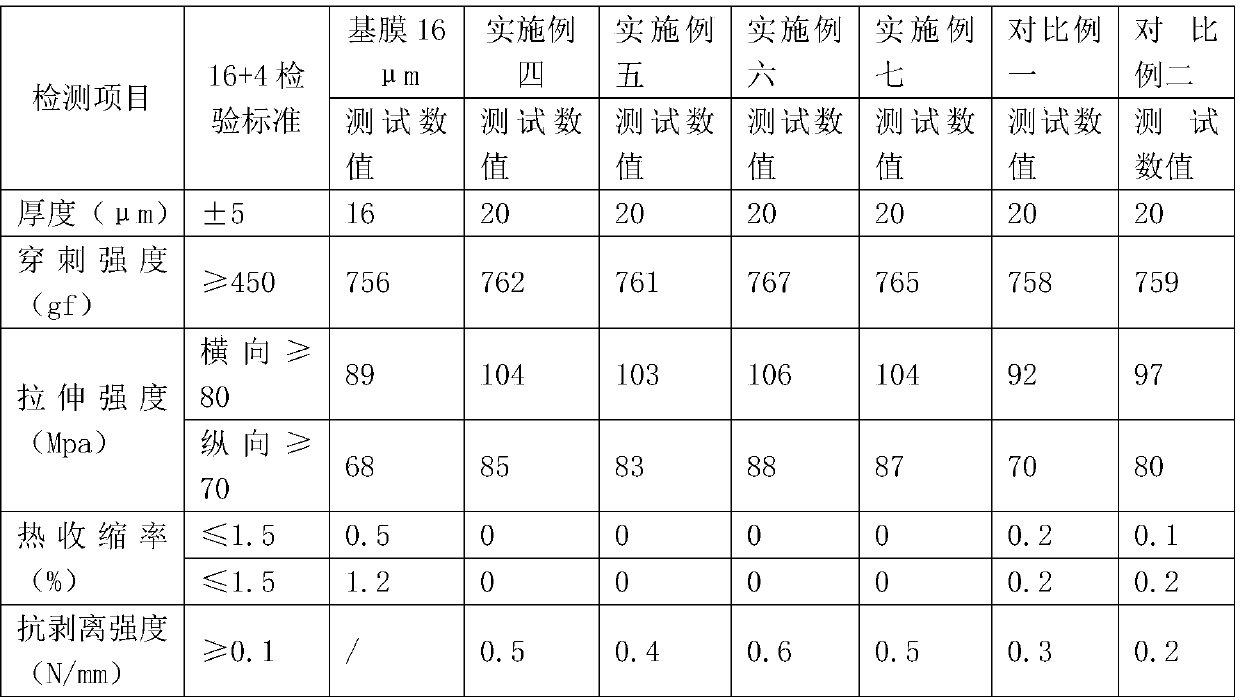

Examples

preparation example 1

[0036] The preparation process of polyvinyl alcohol solution is as follows:

[0037] Add 20 parts by weight of polyvinyl alcohol to 80 parts by weight of deionized water, keep the temperature of the deionized water at 15°C, stir for 20 minutes, then increase the temperature of the water to 50°C, and stir for 10 minutes.

preparation example 2

[0039] The preparation process of polyvinyl alcohol solution is as follows:

[0040] Add 22 parts by weight of polyvinyl alcohol to 90 parts by weight of deionized water, keep the temperature of the deionized water at 20°C, stir for 18 minutes, then increase the temperature of the water to 60°C, and stir for 8 minutes.

preparation example 3

[0042] The preparation process of polyvinyl alcohol solution is as follows:

[0043] Add 25 parts by weight of polyvinyl alcohol to 100 parts by weight of deionized water, keep the temperature of the deionized water at 25°C, stir for 15 minutes, then increase the temperature of the water to 70°C, and stir for 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com