Adhesive and adhesive sheet

A technology of adhesives and compounds, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of poor re-peelability, bad conditions, high adhesion, etc., and achieve good re-peelability, Suppresses the increase of adhesion and has good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

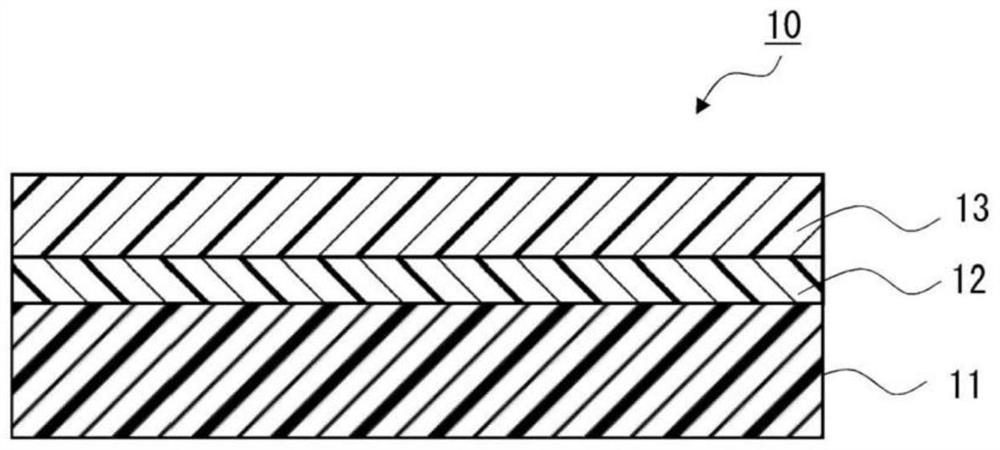

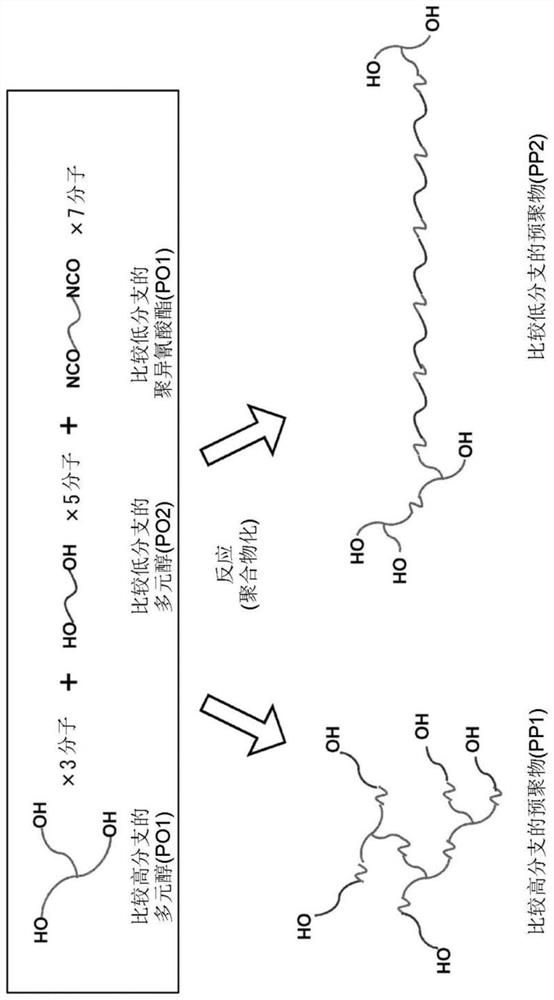

[0074] In the adhesive agent according to the first embodiment of the present invention, one or more active hydrogen group-containing compounds (H) contain 50% by mass or more of active hydrogen group-containing groups whose branching degree α measured by the GPC-MALS method is 0.5 or less In the compound (HX), the branching degree α measured by the GPC-MALS method in the hydroxyl-terminated urethane prepolymer (UPH) is 0.2 to 0.6.

[0075] In the adhesive of the first embodiment, since the intramolecular crosslinking reaction proceeds early and predominantly while the intermolecular crosslinking reaction is maintained, the initial curability and exposure to a thermal environment, especially a hot and humid environment The re-peelability (the effect of suppressing the increase in adhesion) is good, and it can achieve both a dense structure formed by intramolecular crosslinking and a sparse structure formed by intermolecular crosslinking, so it can form substrate adhesion and sc...

no. 2 approach

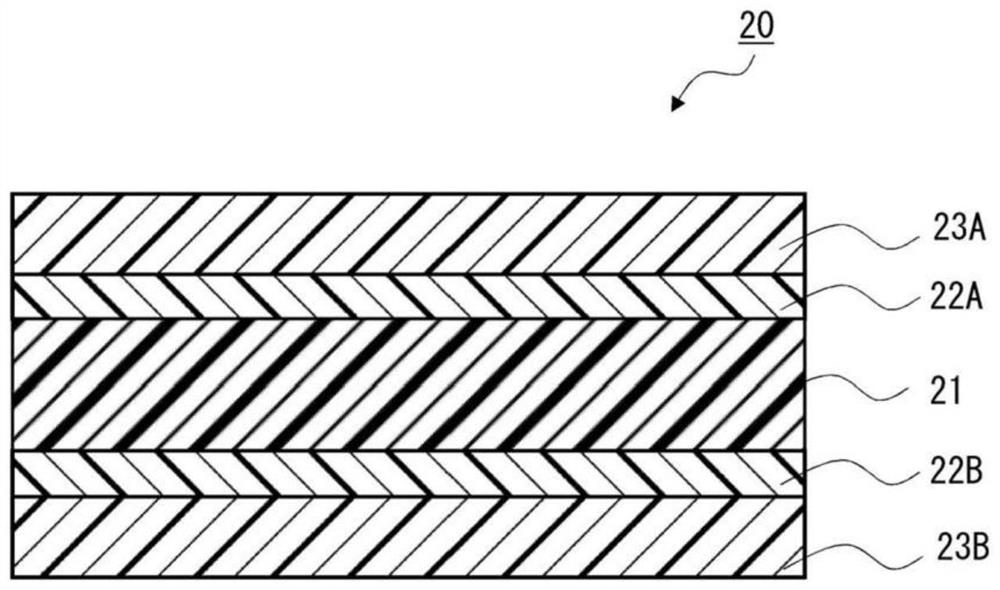

[0083] In the adhesive agent according to the second embodiment of the present invention, one or more active hydrogen group-containing compounds (H) contain 50% by mass or more of active hydrogen group-containing compounds having a branching degree α of more than 0.5 as measured by the GPC-MALS method. In the compound (HY), the branching degree α measured by the GPC-MALS method in the hydroxy-terminated urethane prepolymer (UPH) exceeds 0.6 and is 0.8 or less.

[0084] In the adhesive of the second embodiment, since the crosslinked structure is formed at an early stage by the moderate branched structure contained in the hydroxy-terminated urethane prepolymer (UPH), it is possible to form initial curability and exposure to heat An adhesive layer with good re-peelability (effect of suppressing increase in adhesive force) in an environment, especially a hot and humid environment. In addition, since the adhesive agent of the second embodiment has a structure having a relatively sp...

Embodiment

[0244] Hereinafter, synthesis examples, examples of the present invention, and comparative examples will be described. In addition, in the following description, unless otherwise indicated, "part" means a mass part, "%" means a mass %, and "RH" means a relative humidity. Unless otherwise specified, the unit of the compounding quantity in a table|surface is "mass part." Unless otherwise indicated, the compounding quantity of the component other than a solvent is a non-volatile component conversion value.

[0245] [Evaluation items and evaluation methods for materials or hydroxyl-terminated urethane prepolymers]

[0246] The evaluation items and evaluation methods of the material or the hydroxyl-terminated urethane prepolymer are as follows.

[0247] (Mw, Mn)

[0248] Weight average molecular weight (Mw) and number average molecular weight (Mn) are measured by the gel permeation chromatography (GPC) method. Measurement conditions are as follows. In addition, both Mw and Mn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com