Polyurethane-based hihg-molecular UV absorber

A technology of ultraviolet rays and absorbents, applied in coatings, chemical change-inhibiting compositions, organic chemistry, etc., can solve problems such as poor hydrophilicity, poor fastness, and short service life, and achieve good surface adhesion , Improving the light fastness and excellent washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

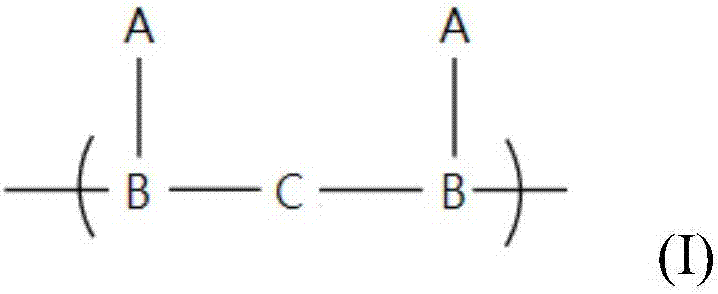

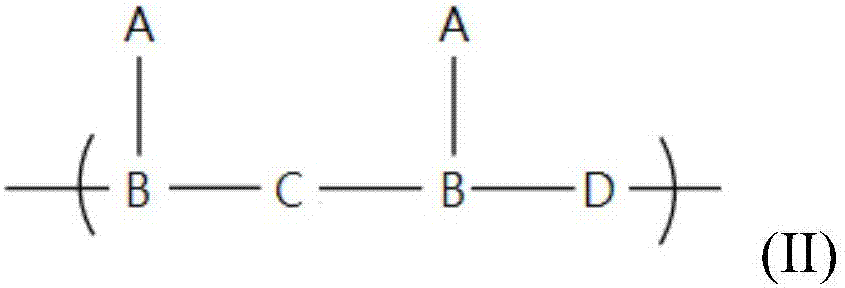

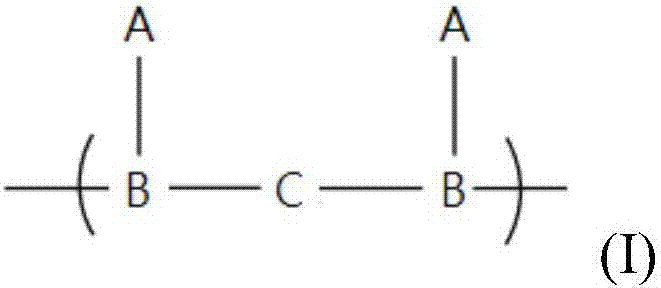

Method used

Image

Examples

preparation example Construction

[0023] The detailed preparation method is described in the following examples, and the method similar to the examples can also be used to prepare the polyurethane polymer ultraviolet absorber. The preparation method (for example: synthesis method, reaction conditions, sequence, etc.) and materials used of the polyurethane-based polymer ultraviolet absorber of the present invention are not limited to those mentioned herein.

[0024] The polyurethane polymer ultraviolet absorber of the invention has excellent water dispersibility, permeability, storage stability, etc., and has a wide range of applications. The polyurethane polymer UV absorber of the present invention is suitable for various substrates, such as but not limited to: fiber materials, leather materials (eg, natural leather, synthetic leather), foamed cotton, wood, and the like. In particular, it is suitable for fibrous materials, including: natural fibers (such as vegetable fibers, animal fibers (such as wool) and mi...

Embodiment 1

[0027] [Example 1] Preparation of Compound 1

[0028] Take 68.2g of α-[3-[3-(2H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-one Propyl]-ω-hydroxypoly(keto-1,2-ethanediyl)(α-[3-[3-(2H-Benzotriazol-2-yl)-5-(1,1-dimethylethyl)- 4-hydroxyphenyl]-1-oxop ropyl]-ω-hydroxypoly(oxo-1,2-ethanediyl), Taiwan Yongguang Chemical Industry Co., Ltd.) into the reaction bottle, add 50.5g HDI TRIMER, heat up to 65 ~ 75 ° C, After the titration NCO functional group molar number reaches the reaction end point (at this moment, Free NCO%=7%), add 5.4g DMBA, then react to after the titration NCO functional group molar number reaches the reaction end point (at this moment, Free NCO%=7%) 3.99%), 16.0 g of acetone and 5.4 g of N,N-dimethylethylamine (N,N-Dimethylethylamine) were added to prepare prepolymer 1.

[0029] Add prepolymer 1 to 300.0g deionized water, and disperse it with a mixer at high speed. After all the addition, add 2.8g EDA and 1.6g AEEA as a chain extender, and stir u...

Embodiment 2

[0030] [Example 2] Preparation of compound 2

[0031] Take 70.0g of α-[3-[3-(2H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-one Propyl]-ω-hydroxypoly(keto-1,2-ethanediyl)(α-[3-[3-(2H-Benzotriazol-2-yl)-5-(1,1-dimethylethyl)- 4-hydroxyphenyl]-1-oxop ropyl]-ω-hydroxypoly(oxo-1,2-ethanediyl), Taiwan Yongguang Chemical Industry Co., Ltd.) into the reaction bottle, add 50.5g HDI TRIMER, heat up to 65 ~ 75 ° C, After titration NCO reactive functional group molar number reaches reaction end point (at this moment, Free NCO%=6.6%), add 2.2g DMBA, 10.5g PEG300 (polyethylene glycol (Polyethylene Glycol), Mw=300), react again to After titrating the molar number of NCO functional groups to reach the end of the reaction (at this time, Free NCO%=2.8%), add 16.0g of acetone and 2.6g of N,N-dimethylisopropylamine (N,N-Dimethylisopropylamine) to prepare the pre- Polymer 2.

[0032] Add prepolymer 2 to 300.0g deionized water, and disperse it with a mixer at high speed. After a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com