Thick-specification high-toughness X80 pipe fitting steel plate and manufacturing method

A manufacturing method and high-toughness technology, which is applied in the field of thick-gauge high-toughness X80 pipe fitting steel plate and its manufacturing field, can solve the problems that it is difficult to guarantee the low-temperature toughness and strength of the pipe fitting steel plate, and it is difficult to guarantee the welding performance and low-temperature toughness of the steel plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

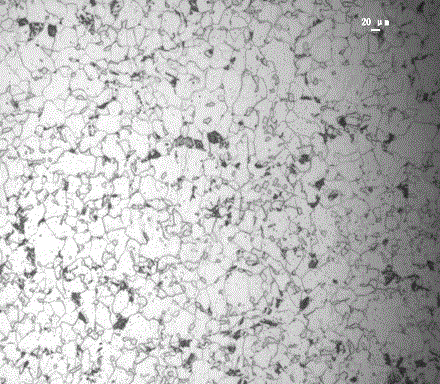

Image

Examples

Embodiment 1

[0032] The thick-gauge high-toughness X80 pipe fitting steel plate in this example is prepared from the following components by mass percentage: C: 0.08%, Si: 0.30%, Mn: 1.85%, P: 0.0064%, S: 0.0016%, Cr : 0.25%, Ni: 0.30%, Nb: 0.070%, Mo: 0.25%, Ti: 0.013%, V: 0.05%, Cu: 0.20%, Pcm=0.23%, Ceq=0.53%, the balance is Fe and unavoidable of impurities.

[0033] The production preparation method of the thick gauge high toughness X80 pipe fitting steel plate of the present embodiment is as follows:

[0034] 1) BOF process: Smelting scrap steel such as high-quality slab edges and billets. After the TSC measurement, quickly pull the gun down to the carbon gun position to ensure that the low gun position time is 1 minute; the tapping time is 6 minutes, and the tapping hole is free Flow, the end temperature of the converter is controlled at = 1660 ° C, the alloy addition sequence: aluminum block - Almanganese ferromanganese - metal manganese - ferrosilicon - ferrochromium - ferroniobiu...

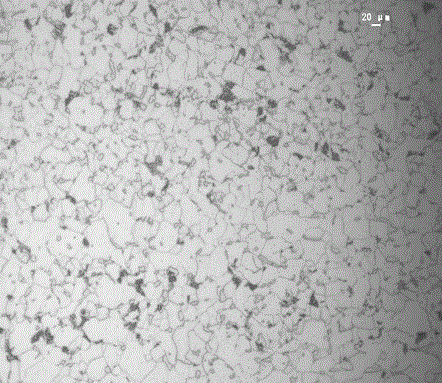

Embodiment 2

[0044] The thick-gauge high-toughness X80 pipe fitting steel plate in this example is prepared from the following components by mass percentage: C: 0.05%, Si: 0.2%, Mn: 1.65%, P: 0.0084%, S: 0.003%, Cr : 0.15%, Ni: 0.15%, Nb: 0.025%, Mo: 0.18%, Ti: 0.013%, V: 0.02%, Cu: 0.10%, Pcm=0.17%, Ceq=0.41%, the balance is Fe and unavoidable of impurities.

[0045] The production preparation method of the thick gauge high toughness X80 pipe fitting steel plate of the present embodiment is as follows:

[0046] 1) BOF process: Smelting scrap steel such as high-quality slab edges and billets. After the TSC measurement is completed, quickly pull the gun down to the carbon gun position to ensure that the low gun position time is 2 minutes; the tapping time is 6 minutes, and the tapping hole is not loose Flow, the end temperature of the converter is controlled at = 1700 ℃, the alloy addition sequence: aluminum block - aluminum manganese ferro - manganese metal - ferrosilicon - ferrochromium ...

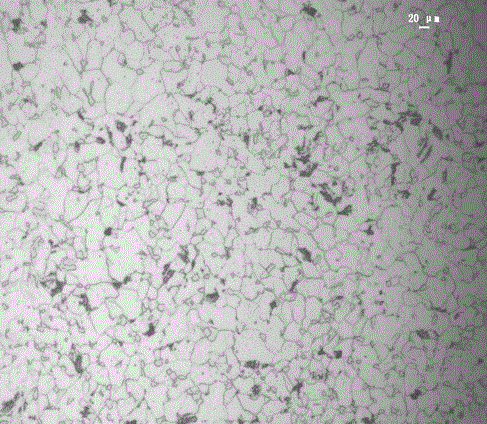

Embodiment 3

[0055] The thick-gauge high-toughness X80 pipe fitting steel plate in this example is prepared from the following components by mass percentage: C: 0.065%, Si: 0.25%, Mn: 1.75%, P: 0.0054%, S: 0.002%, Cr : 0.15%, Ni: 0.26%, Nb: 0.060%, Mo: 0.20%, Ti: 0.013%, V: 0.04%, Cu: 0.15%, Pcm=0.20%, Ceq=0.46%, the balance is Fe and unavoidable of impurities.

[0056] The production preparation method of the thick gauge high toughness X80 pipe fitting steel plate of the present embodiment is as follows:

[0057] 1) BOF process: use high-quality slab edge, waste billet and other scrap steel for smelting, after the TSC measurement, quickly pull the gun down to the carbon gun position, and ensure that the time for the low gun position is 1.5 minutes; the tapping time is 6 minutes, and the tapping hole is free Diffuse flow, the temperature at the end of the converter is controlled at = 1675°C, the order of alloy addition: Aluminum block - Almanganese ferromanganese - metal manganese - ferro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com