High-strength high-toughness pipe for crane boom and manufacturing method for high-strength high-toughness pipe

A manufacturing method and high toughness technology, applied in the field of metallurgical technology, to achieve the effect of simple manufacturing process, good performance uniformity, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

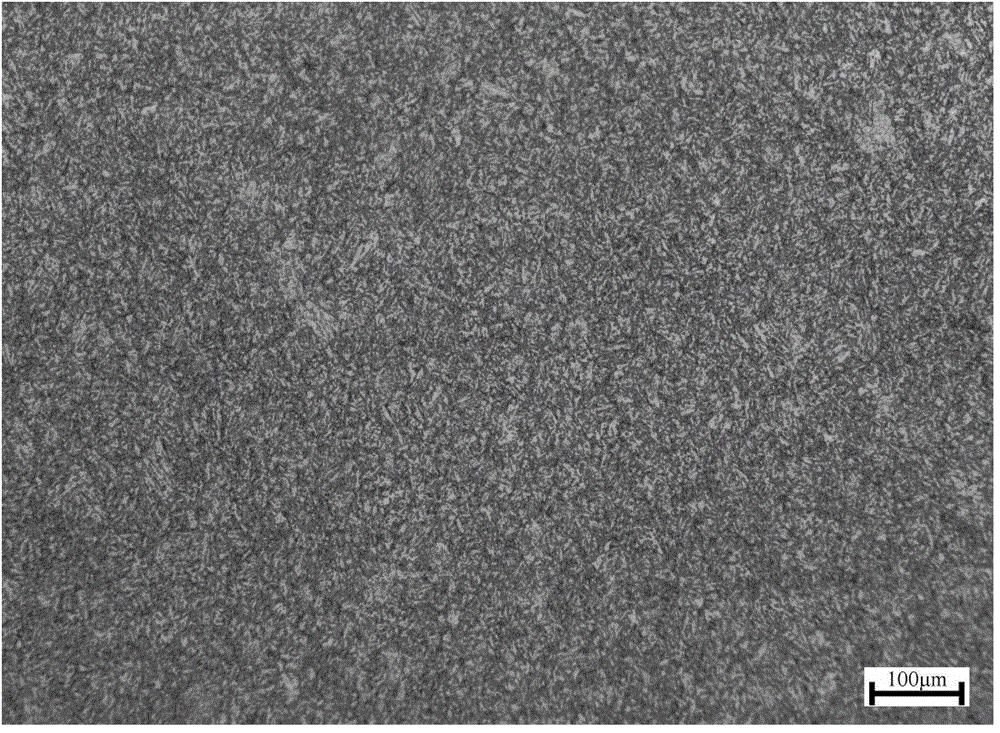

Image

Examples

Embodiment 1

[0023] The mass percentage of the chemical composition of the high-strength and high-toughness crane jib pipe is:

[0024] C 0.15%, Si0.50%, Mn 1.40%, P 0.010%, S 0.008%, Cr 0.46%, Ni 0.13%, Mo 0.34%, V 0.08%, Ti≤0.05%, W 0.40%, Al 0.042%, Cu≤0.02%, Nb≤0.05%, N≤0.007%, the rest are iron and impurities.

[0025] Process route: hot metal pretreatment→converter smelting→LF+VD refining→continuous casting and rolling→hot rolling→heat treatment→flaw detection.

[0026] Refining outside the furnace: Add ferro-titanium 6 minutes before the end of refining.

[0027] Hot rolling process: the heating temperature of the tube billet is 1265°C; the continuous rolling is made of a mandrel with no defects on the surface, and graphite is used for lubrication; the sizing is descaled with high-pressure water.

[0028] Heat treatment process: Quenching and tempering treatment: quenching temperature 930°C to fully austenitize the steel pipe, water quenching to ensure the center line of the steel...

Embodiment 2

[0030] The high-strength and high-toughness crane jib tube has a chemical composition in mass percentage of:

[0031] C 0.17%, Si 0.35%, Mn 1.30%, P 0.013%, S 0.005%, Cr 0.40%, Ni 0.20%, Mo 0.28%, V 0.12%, Ti≤0.05%, W 0.34%, Al 0.03%, Cu ≤0.02%, Nb≤0.05%, N≤0.007%, the remainder is iron and impurities.

[0032] Process route: hot metal pretreatment→converter smelting→LF+VD refining→continuous casting and rolling→hot rolling→heat treatment→flaw detection.

[0033] Refining outside the furnace: Add ferro-titanium 8 minutes before the end of refining.

[0034] Hot rolling process: the heating temperature of the tube billet is 1275°C; continuous rolling is carried out with a mandrel with no defects on the surface, and graphite is used for lubrication; high-pressure water is used for descaling for sizing.

[0035] Heat treatment process: Quenching and tempering treatment: Quenching temperature 925°C to fully austenitize the steel pipe, water quenching to ensure the center line of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com