High-strength steel plate with excellent cold forming property and manufacturing method of high-strength steel plate

A high-strength steel plate and manufacturing method technology, applied in the direction of improving process efficiency, etc., can solve the problems of low production cost and inability to meet the needs of thick steel plates, etc., achieve good cold forming performance, improve cold forming performance, and good welding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

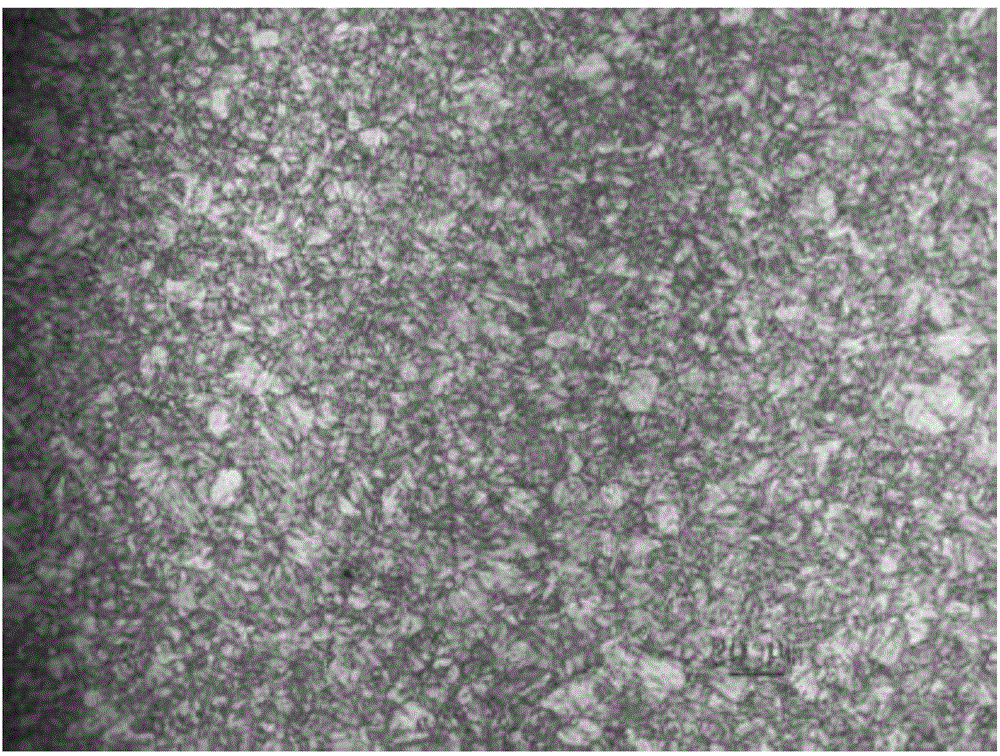

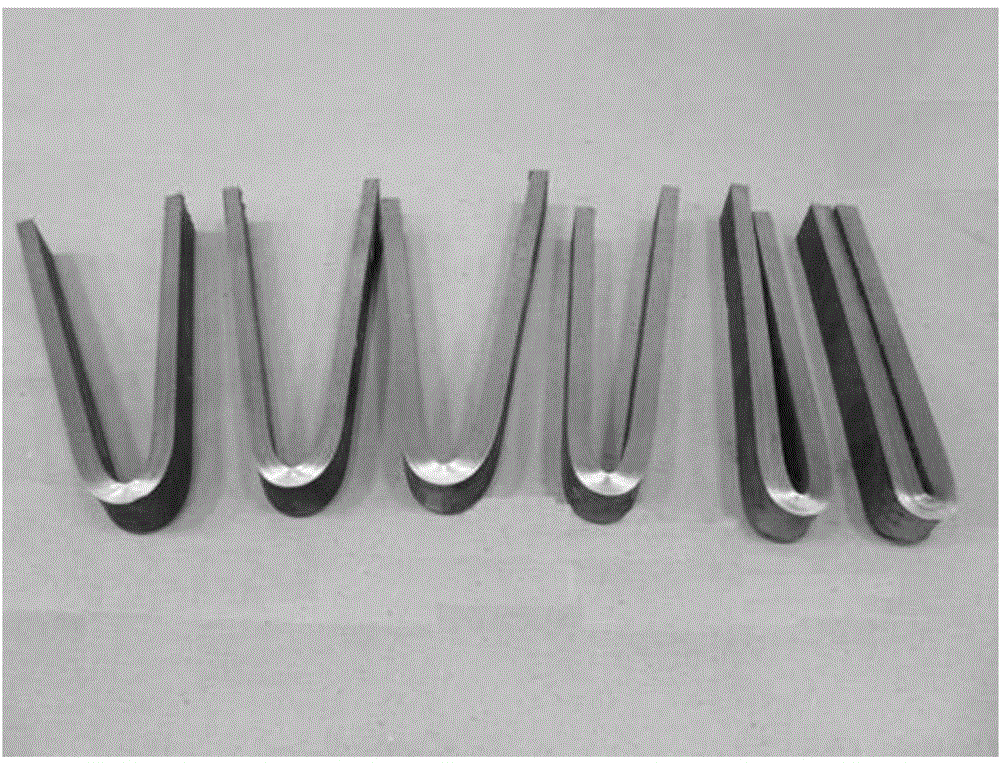

Image

Examples

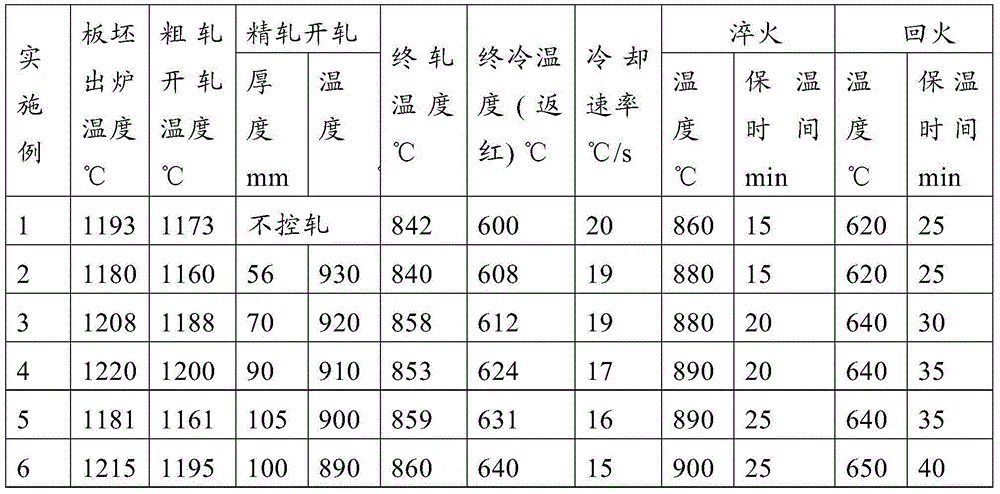

Embodiment 1

[0058] 185 tons of molten iron is smelted in a converter, heated to a temperature of 1300°C, and then 30 tons of scrap steel is added, and 0.13 tons of aluminum is added for deoxidation and alloying using a single slag process, and the slag is blocked in tapping, and the tapping temperature of the converter is controlled between 1620-1660°C. During the tapping process, the ladle must be bottom-blown with argon, and the molten steel must not be exposed. After the molten steel is smelted in the converter, it is refined outside the LF furnace, adding 4.2 tons of ferromanganese, 0.13 tons of ferro-niobium, 1.24 tons of ferrosilicon, 0.84 tons of ferrochrome and 1.36 tons of ferromolybdenum, and then vacuum degassing in the RH process and adding 0.16 tons of ferro-titanium , the vacuum degree of vacuum degassing is 0.25KPa, and the deep vacuum time is 20min; the molten steel is sent to the casting machine for continuous casting, and the superheat of the molten steel is controlled at...

Embodiment 2

[0061] 185 tons of molten iron is smelted in a converter, heated to a temperature of 1300°C, and then 35 tons of scrap steel are added, and 0.15 tons of aluminum is added for deoxidation and alloying using the single slag process, and the tapping temperature of the converter is controlled between 1620-1660°C. During the tapping process, the ladle must be bottom-blown with argon, and the molten steel must not be exposed. After the molten steel is smelted in a converter, it is refined outside the LF furnace, adding 4.3 tons of ferromanganese, 0.10 tons of ferro-niobium, 0.95 tons of ferrosilicon, 0.71 tons of ferrochrome and 0.76 tons of molybdenum. Iron, followed by vacuum degassing in the RH process and adding 0.19 tons of ferrotitanium, the vacuum degree of vacuum degassing is 0.25KPa, and the deep vacuum time is 20min; the molten steel is sent to the casting machine for continuous casting, and the superheat of the molten steel is controlled at 15-50°C Put the slab into the he...

Embodiment 3

[0064] 185 tons of molten iron is smelted in a converter, heated to a temperature of 1300°C, and then 40 tons of scrap steel is added, and 0.16 tons of aluminum is added for deoxidation and alloying using a single slag process, and the slag is blocked in tapping, and the tapping temperature of the converter is controlled between 1620-1660°C. During the tapping process, the ladle must be bottom-blown with argon, and the molten steel must not be exposed. After the molten steel is smelted in the converter, it is refined outside the LF furnace, adding 3.36 tons of ferromanganese, 0.12 tons of ferro-niobium, 0.84 tons of ferrosilicon, 0.80 tons of ferrochrome and 0.42 tons of ferromolybdenum, and then vacuum degassing in the RH process and adding 0.13 tons of ferro-titanium , the vacuum degree of vacuum degassing is 0.25KPa, and the deep vacuum time is 20min; the molten steel is sent to the casting machine for continuous casting, and the superheat of the molten steel is controlled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com