Hot-rolled pickled plate used for hydroformed steel pipe, and manufacturing method thereof

A technology of hot-rolled pickling and hydroforming, which is applied in the field of iron and steel products, can solve the problems of large energy consumption, high production cost, and long production process, and achieve high economic benefits, less alloy content, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

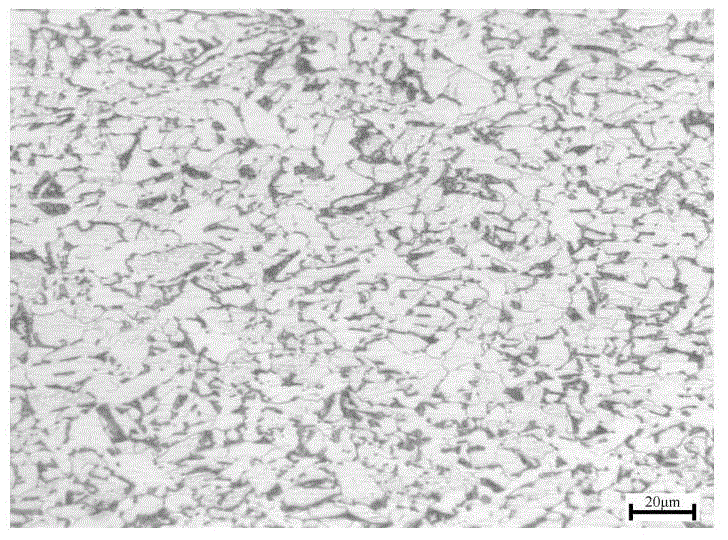

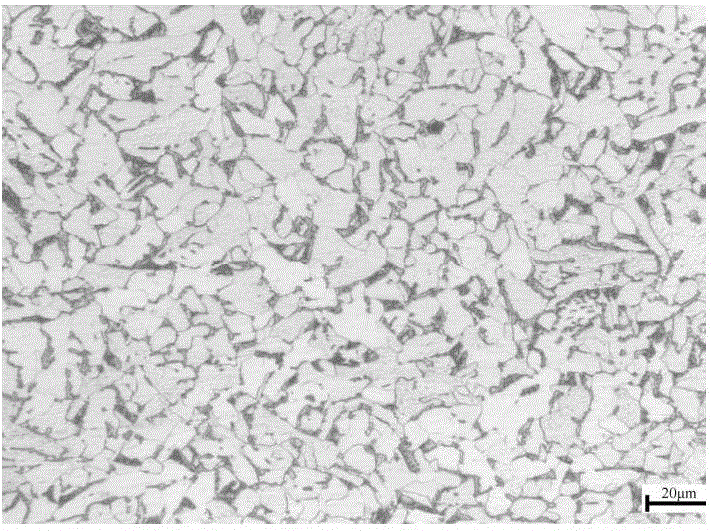

Image

Examples

Embodiment Construction

[0023] Below by embodiment the present invention will be further described.

[0024] The embodiments of the present invention carry out steel plate smelting, rolling, and pickling according to the component ratio of the technical solution; the hydroforming process test of the present invention adopts a steel pipe with a length of 300mm, puts the steel pipe into a test forming machine, fills the pipe with liquid, The two ends are sealed with horizontal punches, the liquid in the steel pipe is pressurized, and the steel pipe is burst through the high-pressure liquid, and then the circumference of the largest rupture of the steel pipe is measured to calculate the expansion rate. The smelting composition of the steel of the embodiment of the present invention is shown in Table 1. The main process parameters of the steel of the embodiment of the present invention are shown in Table 2. The performance of the steel of the embodiment of the present invention is shown in Table 3.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com