Preparation method of low-alloy-cost large-thickness high-low-temperature-toughness 13MnNi6-3 quenched and tempered container steel

A large thickness, high and low temperature technology, applied in the direction of manufacturing converters, etc., can solve the problem of high alloy cost, achieve the effects of low alloy cost, uniform steel plate structure and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

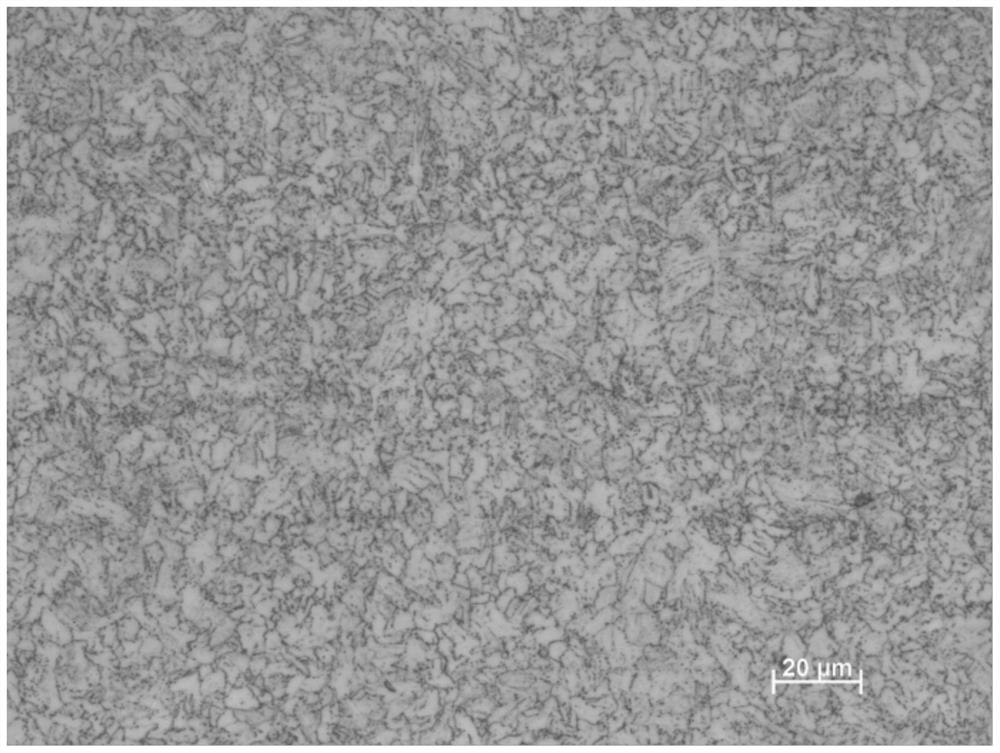

Embodiment 1

[0031] The 13MnNi6-3 steel plate used for the low-temperature pressure vessel of this embodiment has a thickness of 12 mm. The steel is smelted from the following components by mass percentage: C: 0.09%, Si: 0.26%, Mn: 1.50%, P: 0.005%, S : 0.002%, Ni: 0.35%, Nb: 0.030%, Al: 0.037%, Ti: 0.015%, and the balance is Fe and unavoidable impurities.

[0032] (1) Smelting: The molten steel is first desulfurized by KR, then smelted in the converter, sent to the LF refining furnace for refining, and the temperature of the molten steel reaches 1640°C and then transferred to the RH furnace for vacuum degassing treatment; it reaches below 200pa within 10 minutes, and the pressure holding time is ≥ 15 minutes. Add calcium-aluminum wire after vacuum degassing treatment, blow softly for 5 minutes to make the liquid steel composition uniform, and then hang the ladle to pour;

[0033] (2) Continuous casting: it is produced by a slab continuous casting machine with a section of 300mm;

[0034]...

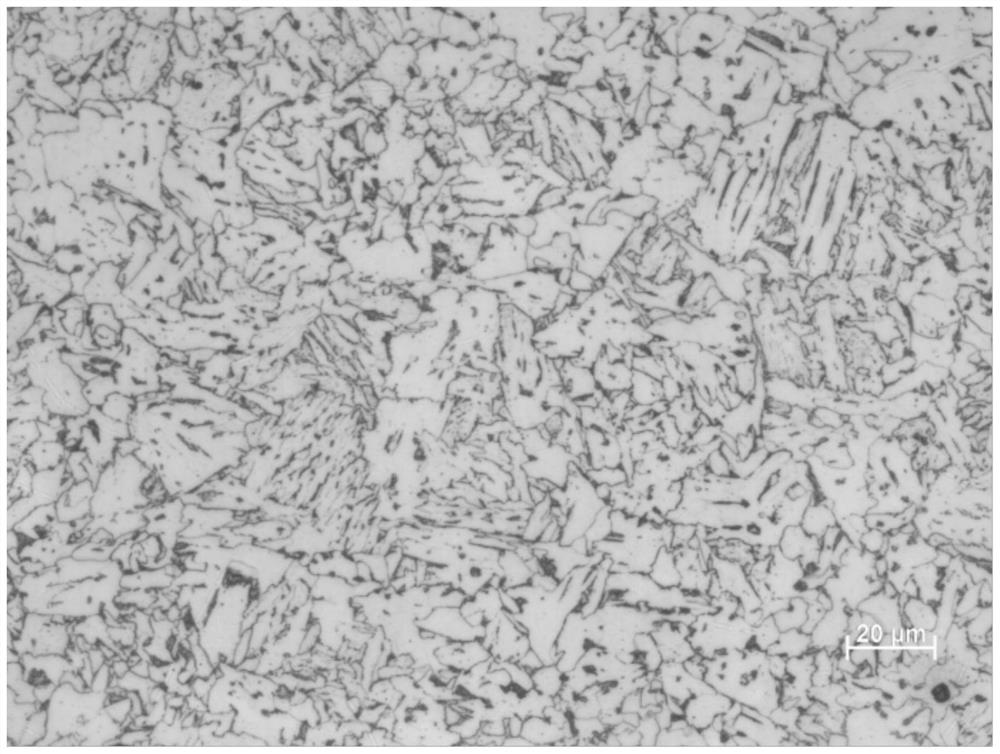

Embodiment 2

[0044] The 13MnNi6-3 steel plate used for the low-temperature pressure vessel of this embodiment has a thickness of 50 mm. The steel is smelted from the following components in mass percentage: C: 0.08%, Si: 0.20%, Mn: 1.55%, P: 0.010%, S : 0.003%, Ni: 0.40%, Nb: 0.020%, Al: 0.050%, Ti: 0.010%, and the balance is Fe and unavoidable impurities.

[0045] (1) Smelting: The molten steel is first desulfurized by KR, then smelted in the converter, sent to the LF refining furnace for refining, and the temperature of the molten steel reaches 1640°C and then transferred to the RH furnace for vacuum degassing treatment; it reaches below 200pa within 10 minutes, and the pressure holding time is ≥ 15 minutes. Add calcium-aluminum wire after vacuum degassing treatment, blow softly for 5 minutes to make the liquid steel composition uniform, and then hang the ladle to pour;

[0046] (2) Continuous casting: it is produced by a slab continuous casting machine with a section of 300mm;

[0047]...

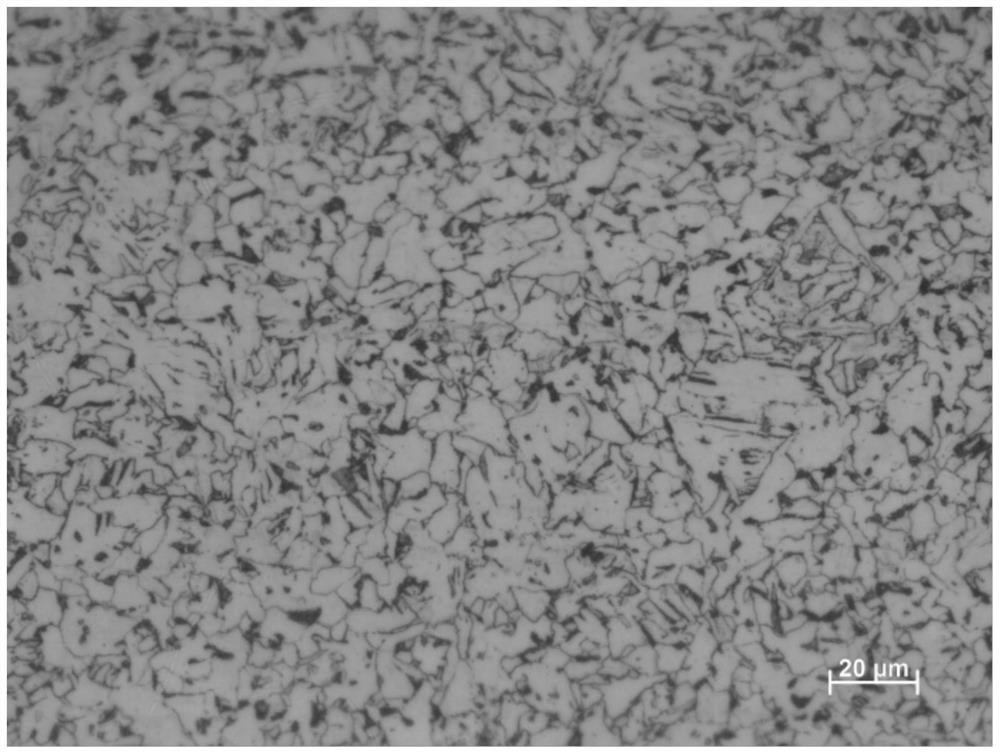

Embodiment 3

[0057] The 13MnNi6-3 steel plate used for the low-temperature pressure vessel of this embodiment has a thickness of 90 mm. The steel is smelted from the following components in mass percentage: C: 0.10%, Si: 0.40%, Mn: 1.40%, P: 0.008%, S : 0.001%, Ni: 0.55%, Nb: 0.025%, Al: 0.050%, Ti: 0.025%, and the balance is Fe and unavoidable impurities.

[0058] (1) Smelting: The molten steel is first desulfurized by KR, then smelted in the converter, sent to the LF refining furnace for refining, and the temperature of the molten steel reaches 1640°C and then transferred to the RH furnace for vacuum degassing treatment; it reaches below 200pa within 10 minutes, and the pressure holding time is ≥ 15 minutes. Add calcium-aluminum wire after vacuum degassing treatment, blow softly for 5 minutes to make the liquid steel composition uniform, and then hang the ladle to pour;

[0059] (2) Continuous casting: it is produced by a slab continuous casting machine with a section of 300mm;

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact energy | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com