Ultramicro-speed closed loop controlling structure for hydraulic forming machine

A hydraulic press and ring control technology, applied in the field of forging hydraulic presses, to achieve high reliability, simple control structure, and stable control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the ultra-micro-speed closed-loop control structure of the forging hydraulic press of the present invention, the following examples are exemplified, and detailed descriptions are as follows in conjunction with the accompanying drawings:

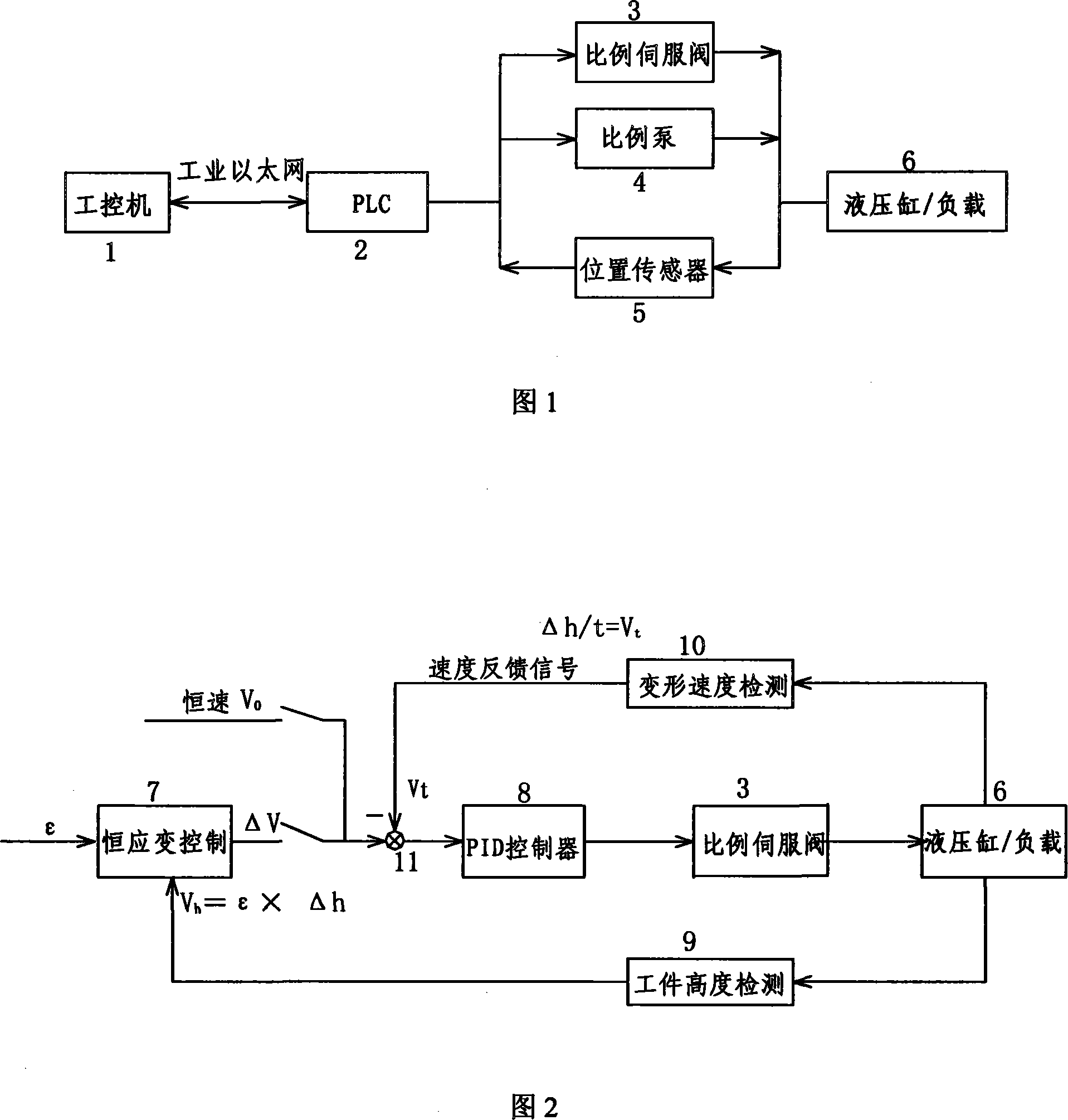

[0016] As shown in Figure 1, the ultra-micro-speed closed-loop control structure of the forging hydraulic press of the present invention includes an industrial computer 1, and a main controller PLC2 for controlling the forging hydraulic press connected to the industrial computer 1 through the industrial Ethernet. The controller PLC2 is connected to one end of the proportional servo valve group 3 and proportional pump group 4 controlled by it, and the other end of the proportional servo valve group 3 and proportional pump group 4 is connected to the hydraulic cylinder 6 of the forging hydraulic machine driven by it. The hydraulic cylinder 6 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com