Isothermal forging method of TC17 titanium alloy disc-shaped forge piece

A technology of isothermal forging and TC17, which is applied in the field of warm forging, can solve the problems of impracticability and achieve the effect of easy forming, good stability and avoiding high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] α+β type two-phase titanium alloy, for example: titanium alloy with Chinese material designation TC17.

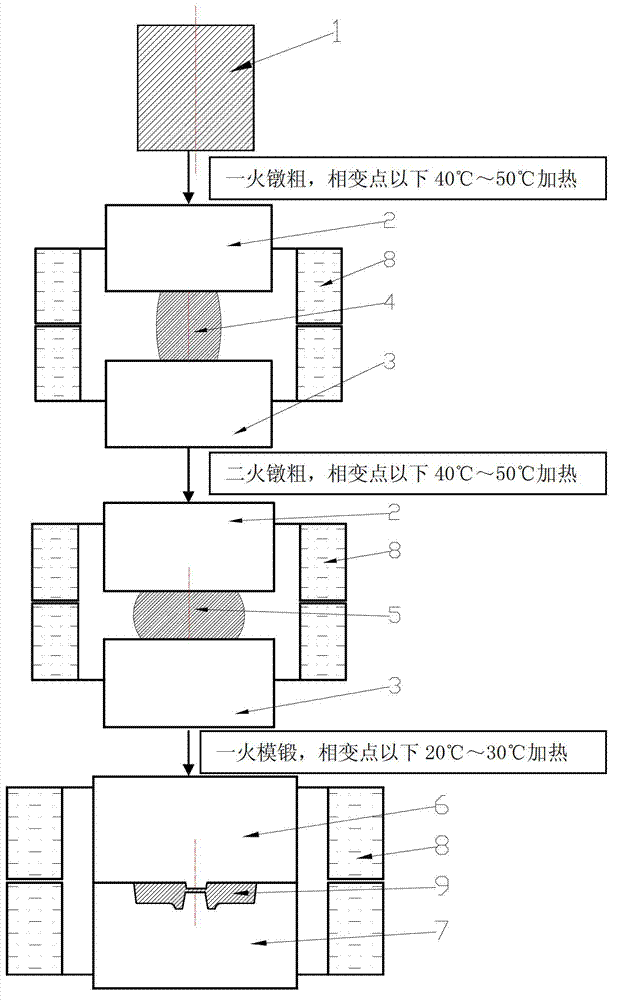

[0021] The near-isothermal forging process steps of TC17 titanium alloy are given below:

[0022] Step 1: Detect that the phase transition point temperature of the TC17 titanium alloy material used is 895°C.

[0023] Step 2: If figure 1 As shown, the TC17 titanium alloy round bar is cut into the ingot 1 according to the forging specification, the ingot 1 is preheated to 300°C, and the surface is sprayed with a special lubricant, and then the ingot 1 is placed in the forging furnace Internal heating to 855°C below the phase transition point of the titanium alloy, heat preservation, the heat preservation time is calculated based on the effective thickness of the ingot 0.6min / mm.

[0024] Step 3: Heat the upper flat die 2 and the lower flat die 3 to 855°C below the phase transition point of the titanium alloy. If it is more convenient to take the die, you can spray gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com