Preparation method of ultrafine grain nickel base powder high temperature alloy

A high-temperature alloy and nickel-based powder technology, which is applied in the field of high-temperature alloys, can solve the problems of narrow thermal processing temperature range, high alloying degree, and large deformation resistance, and achieve the elimination of residual dendrites, excellent product quality, and large deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

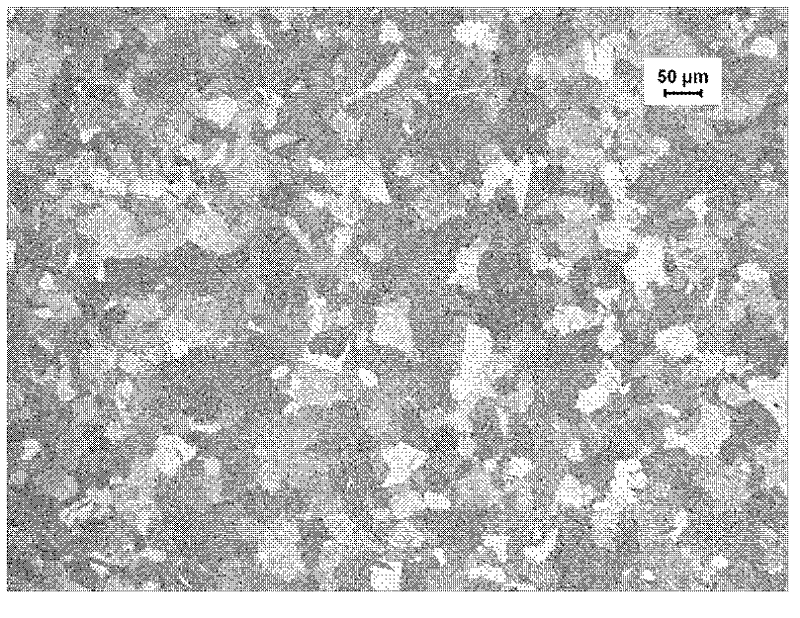

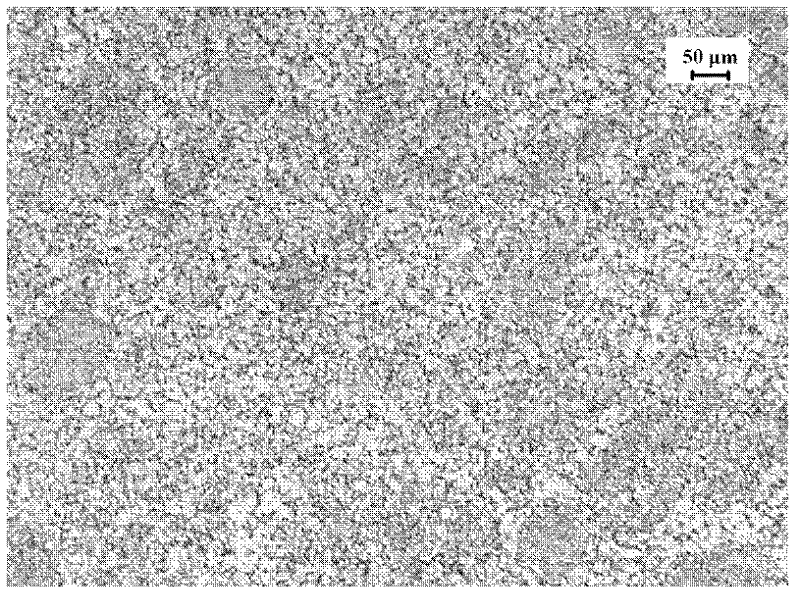

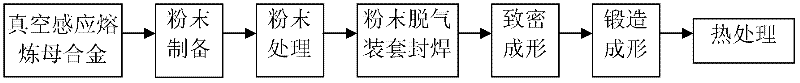

[0016] The invention provides a method for preparing an ultrafine-grained nickel-based powder superalloy. This method utilizes the pinning effect of the grain boundary γ′ particles in the hot deformation process to carry out multi-fire quasi-isothermal forging on the powder superalloy blank densified by hot isostatic pressing in air, and then recrystallization annealing treatment is carried out after forging. Compared with superplastic isothermal forging, the speed is faster, the equipment requirements are lower, and the production cost is reduced. The specific embodiment of the present invention is as follows:

[0017] The first step: determine the forging process parameters. According to the alloy composition and structure characteristics, determine the appropriate forging process parameters, such as deformation temperature, strain rate, maximum deformation, etc. Generally, the complete dissolution temperature range of the γ′-strengthened phase of the nickel-based powder s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com