Thin gauge pipeline steel rolling method

A pipeline steel and thin-gauge technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of increased production cost, low production efficiency, deformation of steel plates, etc., to reduce the temperature drop rate and improve production efficiency , the effect of high furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

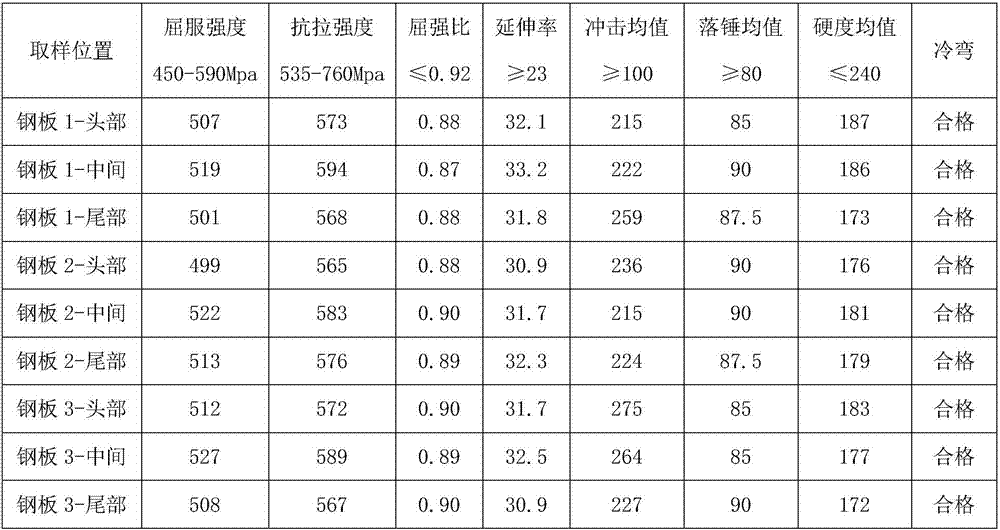

Examples

Embodiment 1

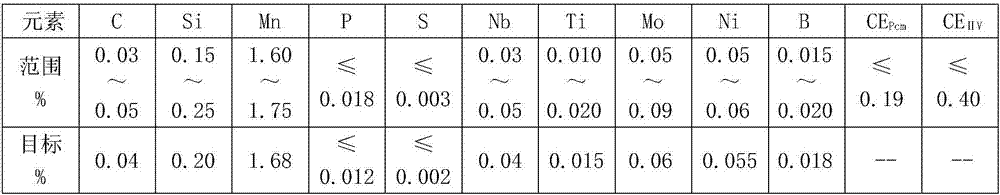

[0021] The production pipeline steel L450M has a dimension of 11×2495×12000mm, and the selected blank size is 200×1450×3000mm. Its melting composition is as follows:

[0022] Melting composition of pipeline steel L450M

[0023]

[0024] 1. The temperature of the heating section is 1170-1240°C; the temperature of the soaking section is 1180-1220°C, the time of the soaking section is 60-80min, and the total time in the furnace is 4-6 hours.

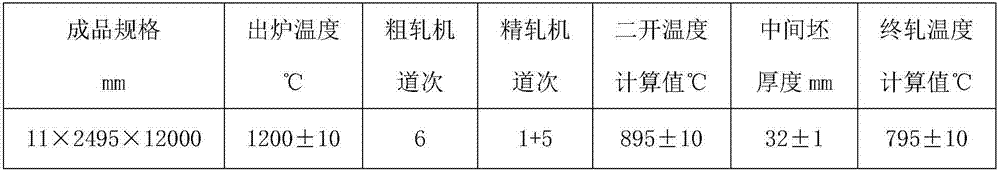

[0025] 2. Rolling process requirements

[0026] a) Before rolling the pipeline steel, modify the thickness of the finish rolling mill to 32mm; adjust the torque of the rough rolling mill to 3600kN·M, and the reduction rate of one pass is 24% during rough rolling and cross rolling, and the reduction rate of two single passes during longitudinal rolling 26%;

[0027] b) After the rough strip is rolled for 6 passes, it is passed to the finish rolling mill for 1 pass, and then it is waited for a second time after the finish rolling mill; ...

Embodiment 2

[0036] The pipeline steel L415M produced has a size specification of 10.5×2500×12000mm, and the selected blank size is 200×1450×3000mm. Its melting composition is as follows:

[0037] Melting composition of pipeline steel L415M

[0038]

[0039] 1. The temperature of the heating section is 1170-1240°C; the temperature of the soaking section is 1180-1220°C, the time of the soaking section is 60-80min, and the total time in the furnace is 4-6 hours.

[0040] 2. Rolling process requirements

[0041] a) Before rolling the pipeline, modify the thickness of the finish rolling mill to 31mm; adjust the torque of the rough rolling mill to 3600kN M, and the reduction rate of one pass is 22% during rough rolling and cross rolling, and the reduction rate of two single passes during longitudinal rolling is 27 %;

[0042] b) After the rough strip is rolled for 6 passes under load, carry out a secondary warm-up before the finish rolling mill;

[0043] c) The second start of rolling st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com