Lithium ion battery thermal management system and method based on phase change material and mutually embedded fins

A lithium-ion battery and thermal management system technology, applied in the field of battery thermal management, can solve problems such as not being able to meet the multiple thermal demands of lithium-ion batteries, and achieve the effect of improving heat dissipation and slowing down the temperature drop rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

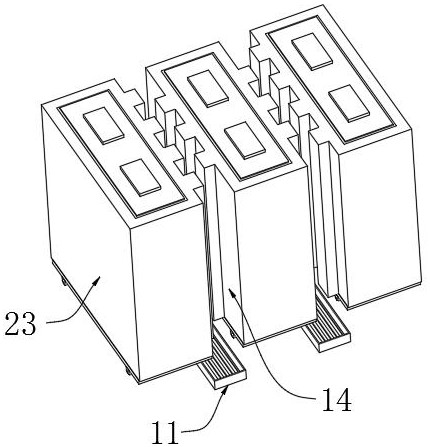

[0052] This embodiment aims to provide one of the better specific implementation structures of the first air intake unit 11 and the first exhaust unit, please refer to image 3 , the first air inlet unit 11 is preferably an air duct, and the air duct communicates with an external cold and heat source. The air duct is provided with a plurality of air outlets, and corresponds to each first heat exchange channel 14 one by one; the first air exhaust The unit is set on the outer wall of the battery box 1; the cold and heat sources can be set away from the battery box 1 to avoid the temperature of the battery box 1 affecting the work of the cold and heat sources; if the battery box is set on an electric car, the air duct can be directly Connected with the car air conditioning system. Specifically, the first air intake unit 11 can blow cold or warm air into the first heat exchange channel 14 as required; It satisfies the heat dissipation and cooling requirements of the battery in hi...

Embodiment 2

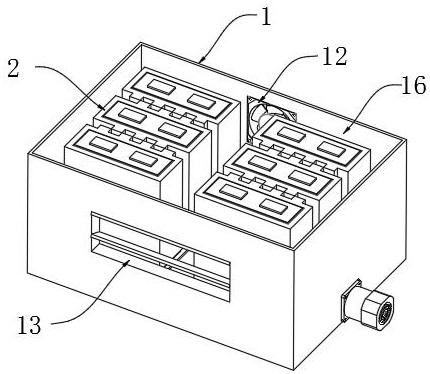

[0054] This embodiment aims to provide one of the better specific implementation structures of the second air intake unit 12 and the second exhaust unit 13. This embodiment can assist Embodiment 1 to obtain better heat dissipation and heat preservation effects, and can be used as Supplementary scheme of embodiment one. see figure 1 The second air intake unit 12 is preferably a heat dissipation fan, and the heat dissipation fan sends the cold air outside the battery box 1 into the second heat exchange channel 15 and / or the third heat exchange channel 16, and can control the air intake rate; The second exhaust unit 13 is preferably an electric louver, which discharges the hot air absorbed in the second heat exchange channel 15 and / or the third heat exchange channel 16, and the electric louver can adjust the opening degree and the air outlet direction. Preferably, a heating wire is provided between the cooling fan and the battery box 1 to blow hot air into the battery box 1 by m...

Embodiment 3

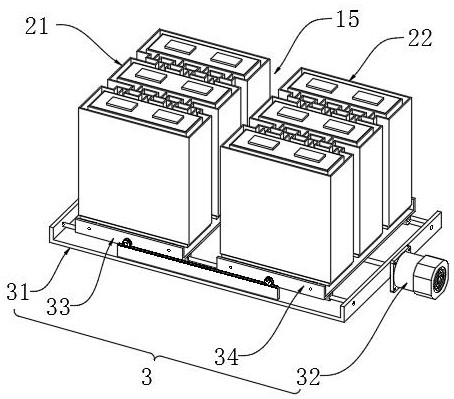

[0056] This embodiment aims to provide one of the preferred specific implementation structures of the driving device 3 . see figure 2 and Figure 5-7 , the driving device 3 includes a base 31, the base 31 is arranged on the inner surface of the bottom of the battery box 1, the base 31 is rotationally connected with the first two-way screw rod 311, and one end of the first two-way screw rod 311 runs through the battery box 1 Afterwards, it is connected to a motor 32 in transmission, and the motor 32 is electrically connected to the controller. Setting the motor 32 outside the battery box 1 can ensure its own heat dissipation, and can also reduce the outline size of the battery box 1 at the same time. Wherein, the two ends of the first two-way screw rod 311 are threadedly connected with the first sliding seat 33 and the second sliding seat 34 respectively, and the first sliding seat 33 and the second sliding seat 34 have the same structure and are respectively slidably connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com