650 DEG C high temperature-resistant titanium alloy material and preparation method thereof

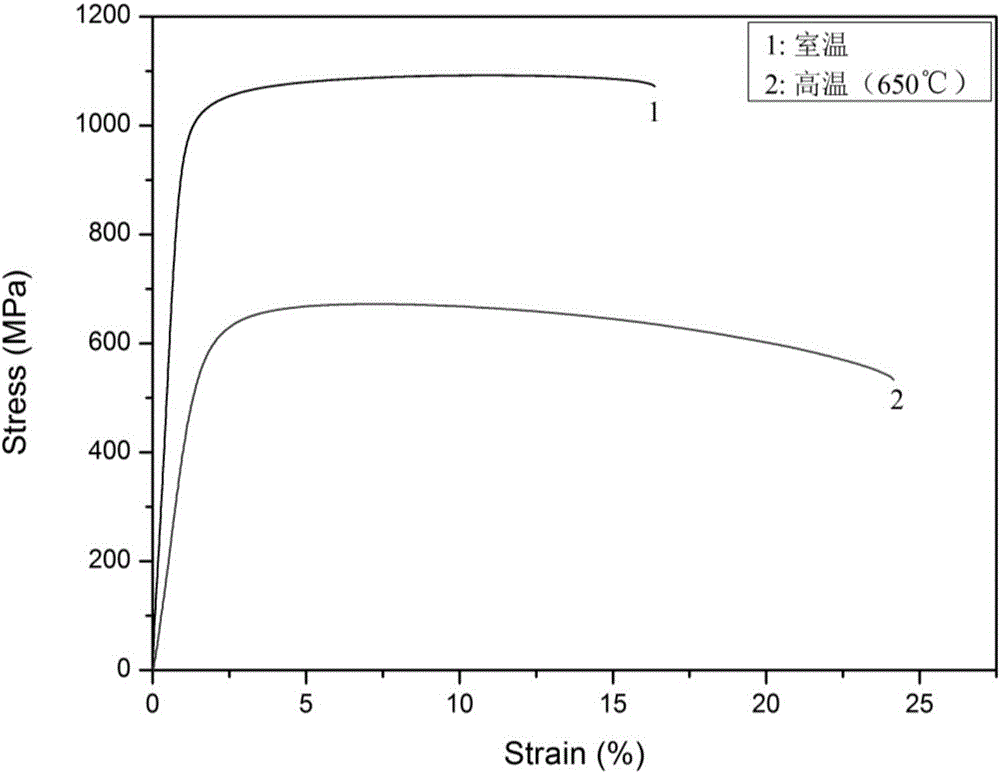

A high-temperature titanium alloy and alloy technology, applied in the field of titanium alloy materials, can solve the problems of poor strength and plasticity, and achieve the effects of high strength and plasticity, increased content, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

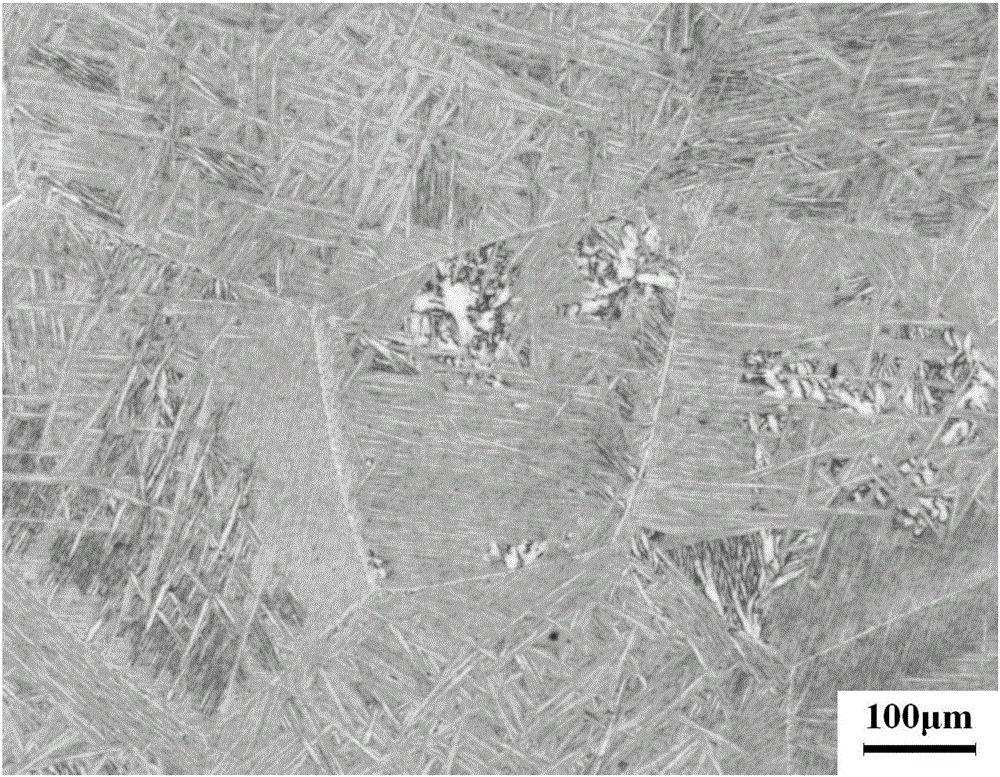

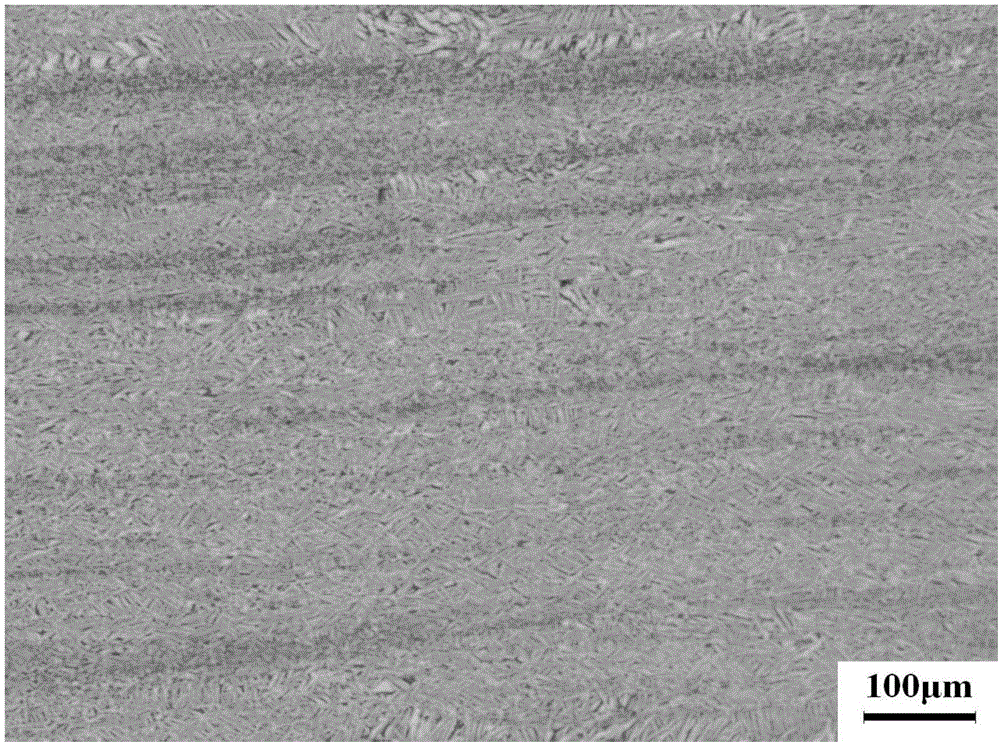

Image

Examples

Embodiment 1

[0023] A new 650°C high-temperature resistant titanium alloy material according to the present embodiment consists of Al: 6.5%, Sn: 2.5%, Zr: 9%, Mo: 0.5%, Nb: 1%, W: 1%, Si: 0.25%, Er: 0.1% and the rest made of Ti.

[0024] The preparation method of a novel 650°C high-temperature resistant titanium alloy material according to this embodiment is carried out according to the following steps:

[0025] 1. Use zero-grade sponge titanium, high-purity aluminum, sponge zirconium, high-purity silicon, and TiSn, AlMo, AlNb, AlW, and AlEr master alloys as raw materials, weigh them, and press the weighed raw materials in a mold to form a Cylindrical blanks are convenient for later smelting preparation. Put the pressed billet into a resistance furnace and heat it to about 100°C to remove the moisture of the billet.

[0026] 2. The alloy ingot is prepared by using a water-cooled copper crucible vacuum induction suspension melting furnace. Put the pressed billet into the crucible, vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com