Large-scale forging dies for near-isothermally forging disc forgeable piece

A disk-shaped forging, isothermal forging technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the waste of precious high-temperature alloy materials, poor interchangeability of the overall forging die, waste, etc. problems, to achieve the effect of saving precious superalloy materials, reducing the difficulty of machining, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

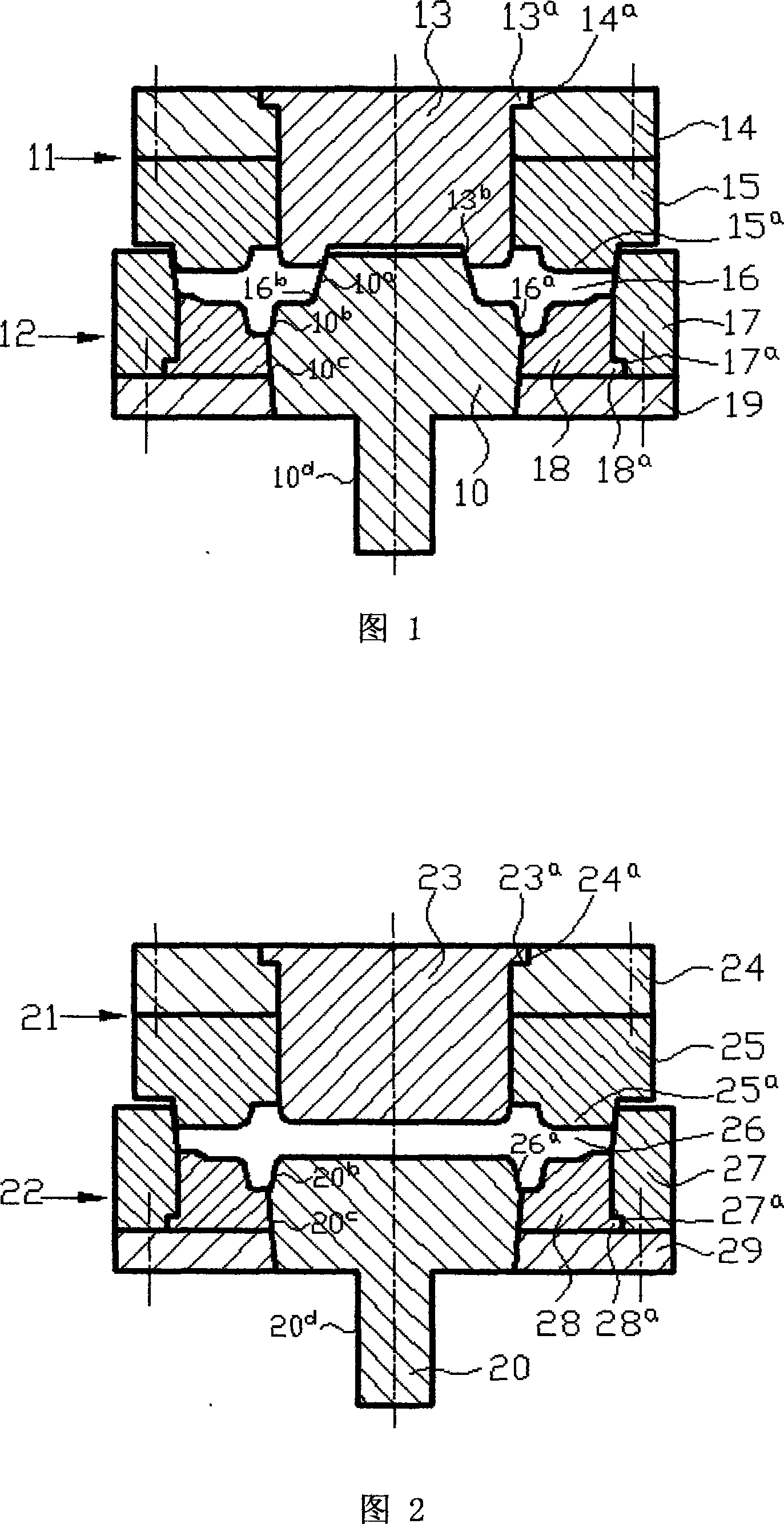

[0036] Fig. 1 shows the longitudinal section structure of the first large-scale forging die along its center line of near isothermal forging disc forging, this forging die is made up of upper forging die 11 and lower forging die 12, described upper forging die 11 and lower forging die The forging die 12 is formed by combining and assembling a plurality of modules respectively.

[0037] Upper forging die 11 is made up of upper die base 14, upper die core block 13 and upper die surface block 15. The upper mold base 14 is a ring structure and there is a ring 14 larger than the inner annular surface at the position where the top of the inner annulus of the mold base intersects with the upper end surface a ; The upper mold core block 13 is a cylindrical structure, and there is a raised ring 13 at the intersection of the upper part of its outer peripheral surface and its upper end surface a , there is a circular groove 13 with a slope in the middle of its bottom end face b ;The up...

Embodiment 2

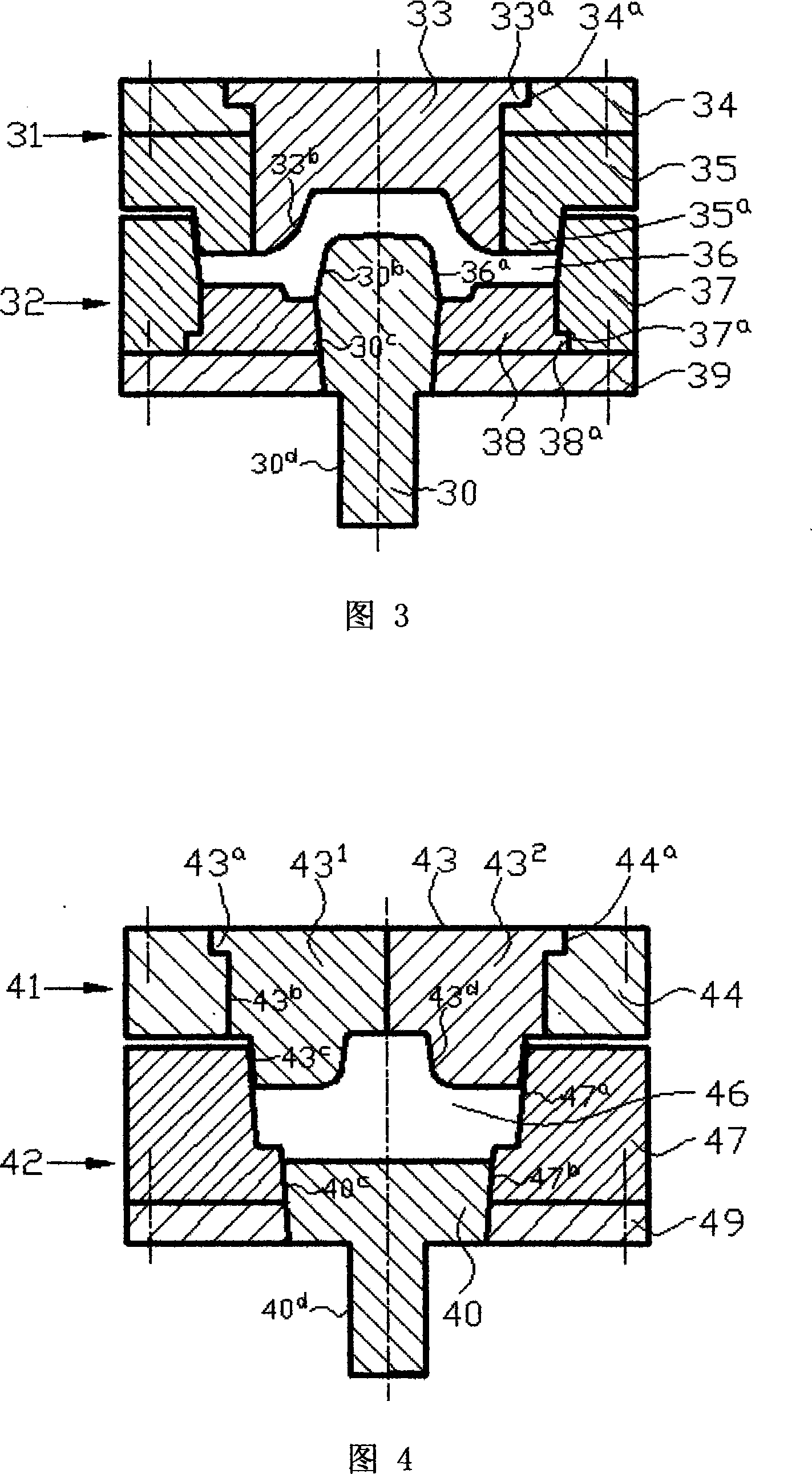

[0043] Fig. 2 shows the longitudinal section structure of the second large-scale forging die along its center line of near isothermal forging disc forging, and this forging die is made up of upper forging die 21 and lower forging die 22, and described upper forging die 21 and lower forging die The forging die 22 is formed by combining and assembling a plurality of modules respectively.

[0044] Upper forging die 21 is made up of upper die base 24 , upper die core block 23 and upper die surface block 25 . The upper mold base 24 is a ring structure and there is a ring 24 larger than the inner annular surface at the position where the top of the inner annulus of the mold base intersects with the upper end surface a ; The upper mold core block 23 is a cylindrical structure, and there is a raised ring 23 at the intersection of the upper part of its outer peripheral surface and its upper end surface a ;The upper mold surface block 25 is a ring structure, and there is a raised ring ...

Embodiment 3

[0050] Fig. 3 shows the longitudinal section structure of the third large-scale forging die along its center line of nearly isothermally forging disc-shaped forgings, this forging die is made up of upper forging die 31 and lower forging die 32, and described upper forging die 31 and lower forging die The forging die 32 is formed by combining and assembling a plurality of modules respectively.

[0051] Upper forging die 31 is made up of upper die base 34 , upper die core block 33 and upper die surface block 35 . The upper die base 34 is a ring structure and there is a ring 34 larger than the inner ring surface at the position where the top of the inner ring surface of the die base intersects with the upper end face. a ; The upper mold core block 33 is a cylindrical structure, and there is a protruding ring 33 at the intersection of the upper part of its outer peripheral surface and its upper end surface a , there is a circular groove 33 with a slope in the middle of its bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com