Beta phase nearly isothermal forging of high-damage tolerant titanium alloy TC4-DT

A TC4-DT, isothermal forging technology, applied in the field of warm forging technology, can solve problems such as reducing plasticity, and achieve the effects of improving strength, improving fracture toughness, and stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

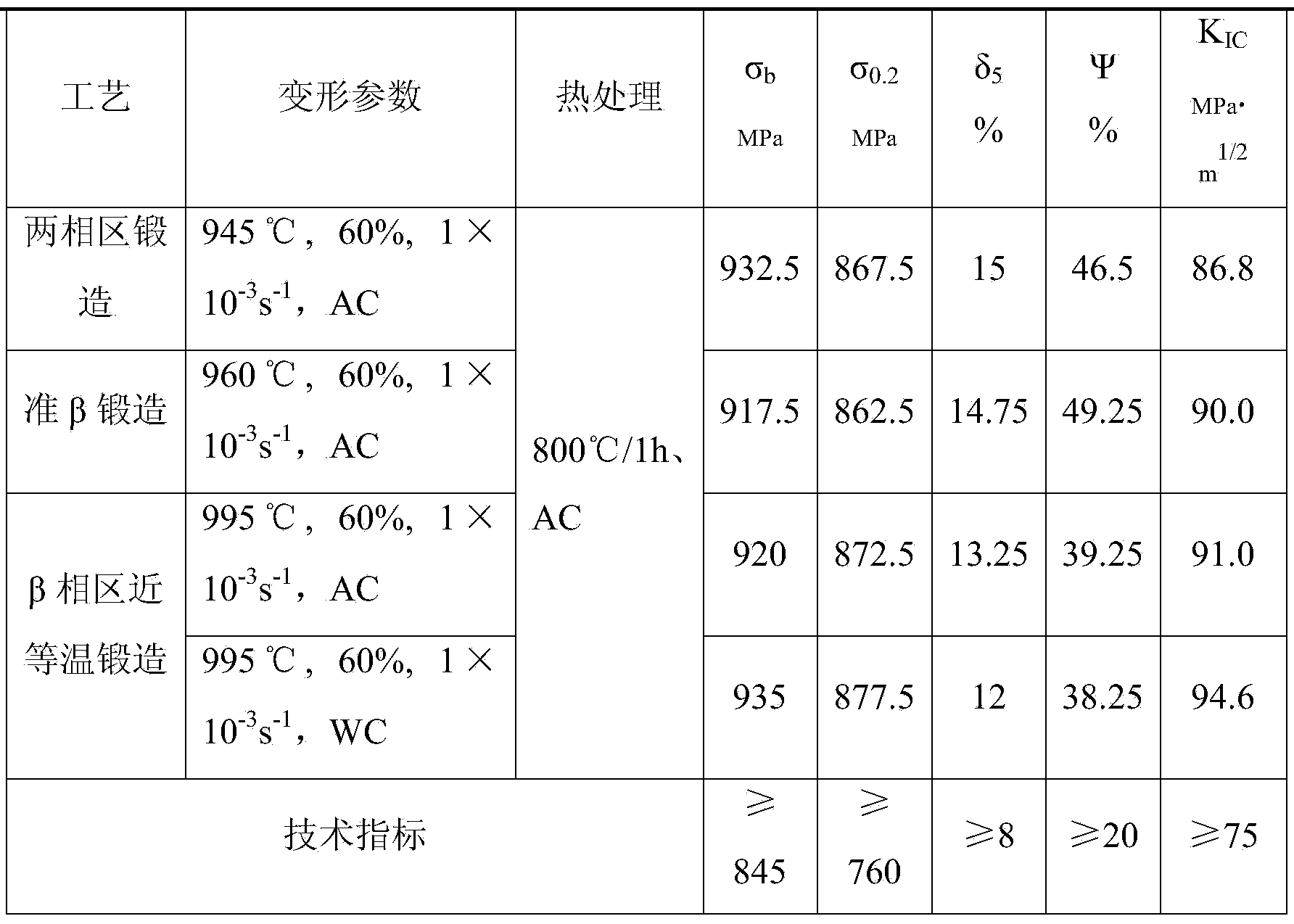

[0020] The mechanical properties of TC4-DT titanium alloy after adopting the above-mentioned β-phase region near-isothermal forging process can be seen from Table 1. Compared with the traditional two-phase region forging and quasi-β forging, on the basis of ensuring good plasticity, its Both strength and fracture toughness are improved.

[0021] Table 1 Mechanical properties after near-isothermal forging in β phase region, two-phase region forging and quasi-β forging

[0022]

Embodiment 2

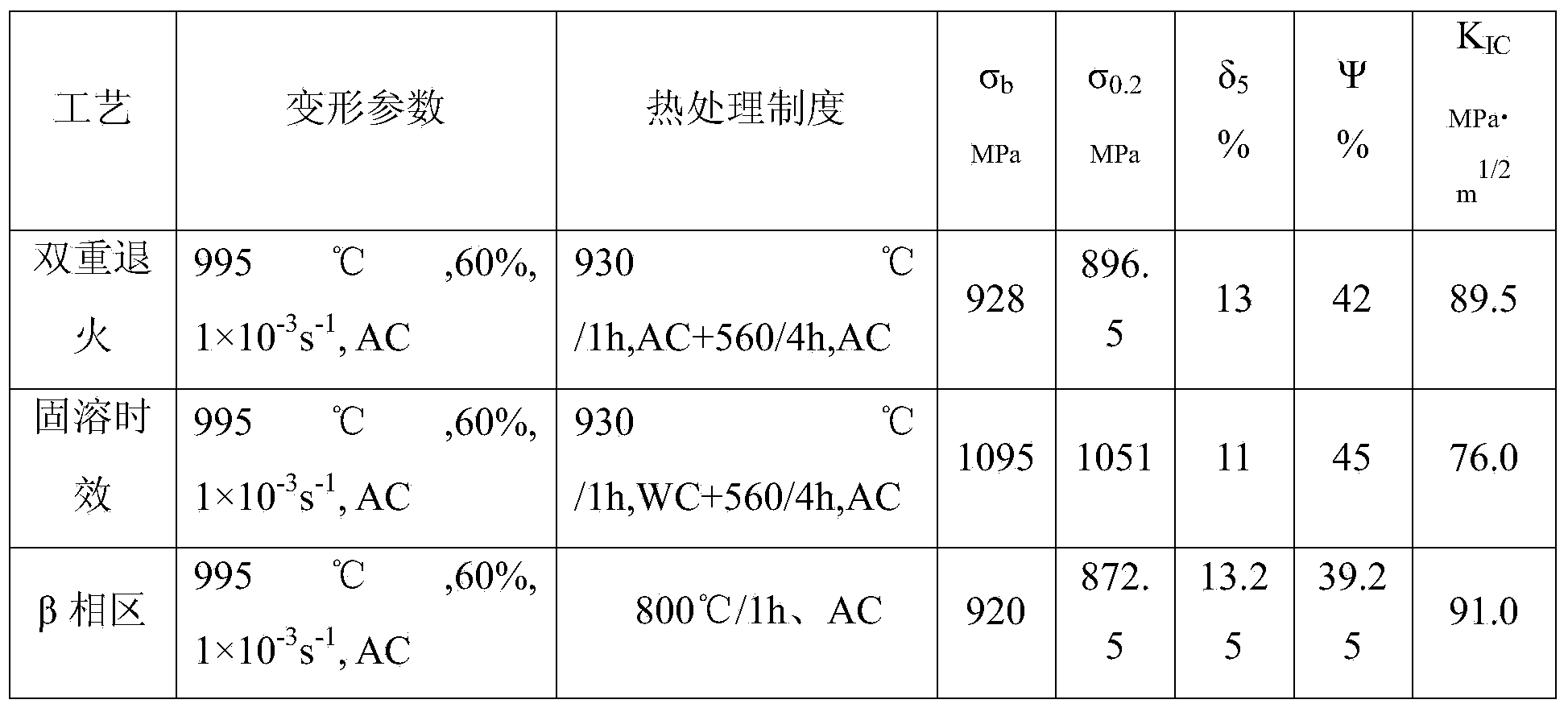

[0024] The same material specifications and deformation conditions as in Example 1 were adopted, except that the final heat treatment was changed to a double annealing and solution aging system in the two-phase region, and their respective mechanical properties are listed in Table 2. It can be seen from the table that under the same deformation conditions, different heat treatment systems have a significant impact on its properties. Although solution aging can greatly increase the strength, its fracture toughness is significantly reduced, which is still not as good as that of near isothermal steel. Forged performance is reliable.

[0025] Table 2 Mechanical properties after near-isothermal forging in the β phase region and different heat treatment systems

[0026]

[0027]

Embodiment 3

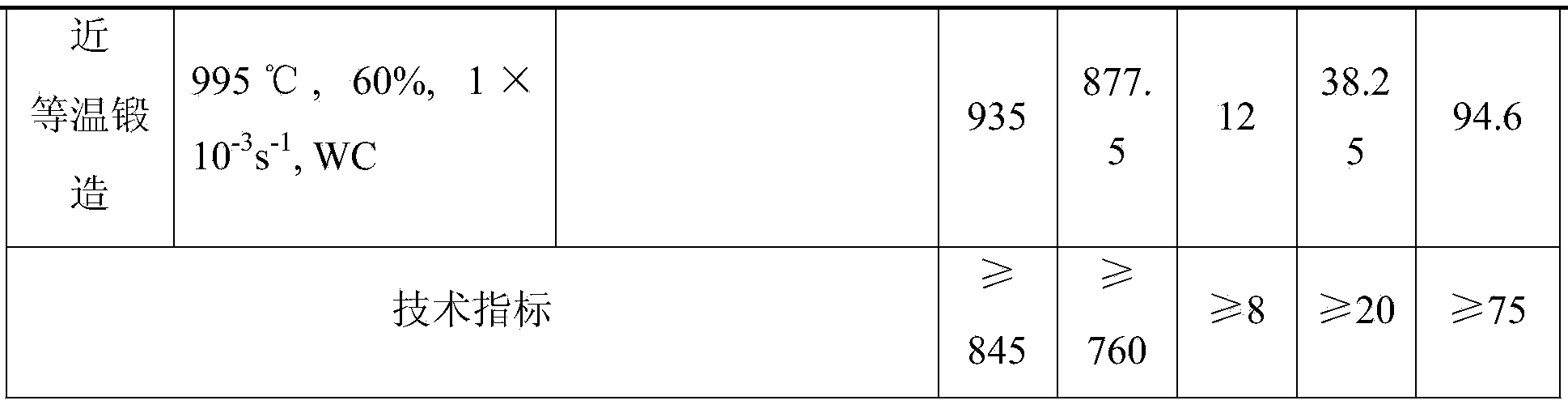

[0029] Table 3 shows the performance comparison results of the TC4-DT titanium alloy using the above-mentioned near-isothermal forging process in the β phase region and the conventional β heat treatment and quasi-β heat treatment processes. It can be seen from Table 3 that near-isothermal forging in the β phase region can obtain a good strength-plasticity-toughness matching, and the performance is stable and reliable. Although there are also processes that meet the requirements in the β heat treatment, the overall performance matching is not as good as that of β The phase area is near isothermal forging, and the performance is unstable.

[0030] Table 3 Mechanical properties of TC4-DT titanium alloy with equiaxed original structure after different thermomechanical treatments

[0031]

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com