Isothermal forging method of TiAl alloy

An isothermal forging and alloying technology, which is applied in the processing of intermetallic compound alloy targets, can solve the problems of high brittleness, high hardness, material cracks, etc., and achieve the effect of uniform structure and overcoming high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

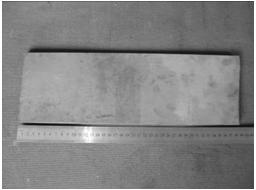

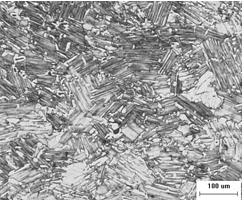

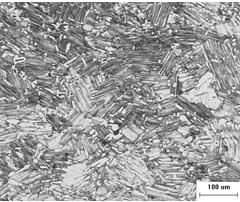

Image

Examples

Embodiment 1

[0020] Forging TiAl alloy by isothermal forging technology, the specific steps are as follows:

[0021] (a) Material flaw detection: After smelting TiAl (the mass percentage content of Ti is 87.5%, and the mass percentage content of Al is 12.5%) alloy ingots are turned to remove surface scale and visible crack defects, and ultrasonic flaw detection is used Confirm that the material has no defects such as pores;

[0022] (b) Heating and heat preservation of machine molds: Equip a 630-ton press with a heat preservation furnace with a heating device to ensure that the mold temperature is 850°C and that the temperature during the forging process is 850°C;

[0023] (c) Material surface treatment: Coat the surface of the defect-free TiAl alloy with a high-temperature oxidation-resistant coating. Thickness 0.1mm, only need to paint once, let it dry for a while and heat it in the furnace;

[0024] (d) Material heat treatment: heat a TiAl alloy with a diameter of 100mm coated with a ...

Embodiment 2

[0027] Forging TiAl alloy by isothermal forging technology, the specific steps are as follows:

[0028] (a) Material flaw detection: After smelting TiAl (the mass percentage content of Ti is 75% and the mass percentage content of Al is 25%) alloy ingot is turned to remove surface scale and crack defects visible to the naked eye, and ultrasonic flaw detection is used Confirm that the material has no defects such as pores;

[0029] (b) Heating and heat preservation of machine molds: equip a 630-ton press with a heat preservation furnace with a heating device to ensure that the mold temperature is 900°C and that the temperature during the forging process is 900°C;

[0030] (c) Material surface treatment: Coat the surface of the defect-free TiAl alloy with a high-temperature oxidation-resistant coating. Thickness 0.2mm, only need to paint once, let it dry for a while and put it into the furnace for heating;

[0031] (d) Material heat treatment: heat a TiAl alloy with a diameter ...

Embodiment 3

[0034] Forging TiAl alloy by isothermal forging technology, the specific steps are as follows:

[0035] (a) Material flaw detection: After smelting TiAl (the mass percentage content of Ti is 64%, and the mass percentage content of Al is 36%) alloy ingots are turned to remove surface scale and visible crack defects, and ultrasonic flaw detection is used Confirm that the material has no defects such as pores;

[0036] (b) Heating and heat preservation of machine molds: Equip a 630-ton press with a heat preservation furnace with a heating device to ensure that the temperature of the mold is 880°C, and that the temperature during the forging process is 880°C;

[0037] (c) Material surface treatment: Coat the surface of the defect-free TiAl alloy with a high-temperature oxidation-resistant coating. Thickness 0.15mm, only need to paint once, let it dry for a while and put it into furnace for heating;

[0038] (d) Material heat treatment: heat the TiAl alloy with a diameter of 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com