Fe-Cr-Mn welding wire as well as preparation method and welding process thereof

A technology of fe-cr-mn and welding wire, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problem of high cost and achieve the effect of reducing welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

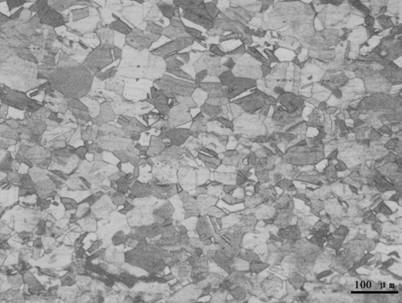

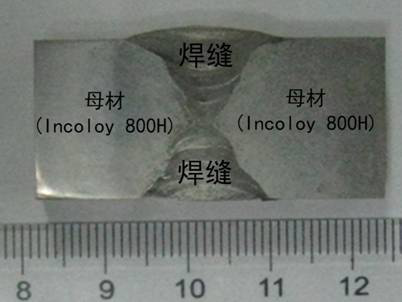

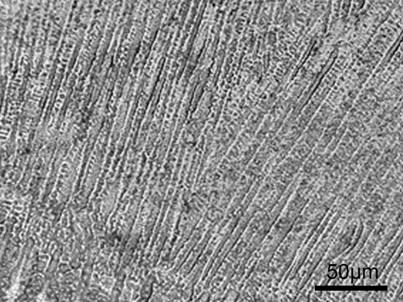

Examples

preparation example Construction

[0066] On the other hand, the preparation method of the Fe-Cr-Mn welding wire provided in this embodiment is used to prepare the above-mentioned Fe-Cr-Mn welding wire, comprising the following steps:

[0067] Weighing powder: by mass percentage: Cr powder 45.0-48.0%, Ni powder 12.0-14.0%, Mn powder 25.0-28.0%, Ti powder 1.4-1.8%, Al powder 0.6-1.0%, V powder 4.0-5.0%, Graphene 0.3-0.6%, the rest is Fe powder, wherein, the sum of the mass percentages of all the above ingredients is 100%, to weigh the powder;

[0068] Drying the powder: heat the powder in a vacuum environment (for example, a vacuum heating furnace) to remove crystal water in the powder. The heating temperature range is 200-240°C, and the holding time range is 2-4h;

[0069] Mixing powder: fully mix the dried powder, the mixing time range is: 1-3h; specifically, the dried powder can be mixed in a powder mixer;

[0070] Coating powder: remove the grease on the surface of the welding skin, and then wrap the mixed ...

Embodiment 1

[0095] Step 1, weigh the powder: weigh the powder according to mass percentage, wherein, Cr powder 45.0%, Ni powder 12.0%, Mn powder 25.0%, Ti powder 1.4%, Al powder 0.6%, V powder 4.0%, graphene 0.3% %, the rest is Fe powder, and the sum of the mass percentages of the above components is 100%;

[0096] Step 2, drying the medicinal powder: put the medicinal powder weighed in step 1 into a vacuum heating furnace for heating at a heating temperature of 200°C and a holding time of 2 hours to remove the crystal water in the medicinal powder;

[0097] Step 3, mixing the powder: place the dried powder in a powder mixer for full mixing, and the mixing time is 1 hour;

[0098] Step 4, wrapping the powder: use alcohol to remove the grease on the surface of the 304 (06Cr19Ni10) stainless steel strip, and wrap the powder prepared in step 3 in the steel strip through the flux-cored wire drawing equipment;

[0099] Step 5, welding wire drawing: use drawing process to make welding wire, wh...

Embodiment 2

[0104] Step 1, weighing the powder: weigh the powder according to mass percentage, wherein, Cr powder 48.0%, Ni powder 14.0%, Mn powder 28.0%, Ti powder 1.8%, Al powder 1.0%, V powder 5.0%, graphene 0.6% %, the rest is Fe powder, and the sum of the mass percentages of the above components is 100%;

[0105] Step 2, drying the medicinal powder: put the medicinal powder weighed in step 1 into a vacuum heating furnace for heating at a heating temperature of 240°C and a holding time of 4 hours to remove the crystal water in the medicinal powder;

[0106] Step 3, mixing the powder: place the dried powder in a powder mixer for full mixing, and the mixing time is 3 hours;

[0107] Step 4, wrapping the powder: use alcohol to remove the grease on the surface of the 304 (06Cr19Ni10) stainless steel strip, and wrap the powder prepared in step 3 in the steel strip through the flux-cored wire drawing equipment;

[0108] Step 5, welding wire drawing: use drawing process to make welding wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com