Method for plotting roll gap for changing roller under condition of on-line strip steel in rolling mill

A calibration method and roll gap technology, which are applied in the field of HC rolling mill with on-line roll change in cold rolling mills and in the field of rolling mills in cold rolling mills, can solve problems such as errors in roll gap storage data, increase roll change time, and affect other problems, so as to save replacement. Roll time, increased flexibility, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

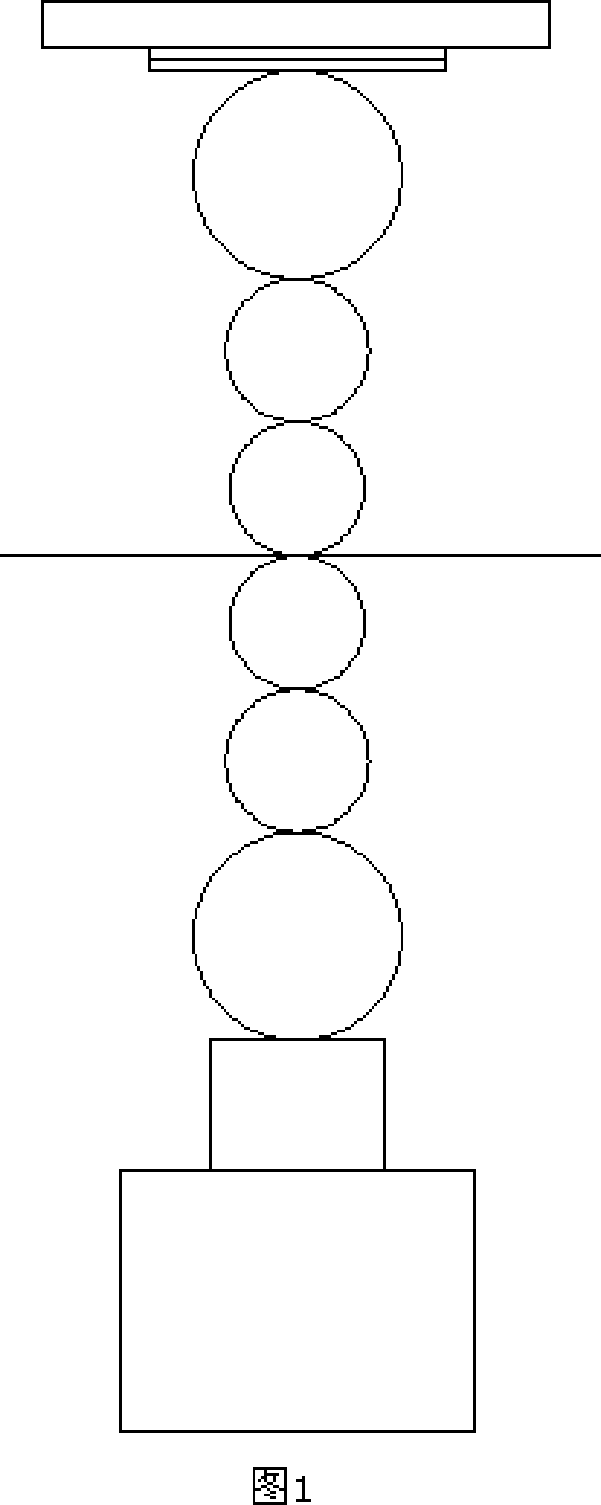

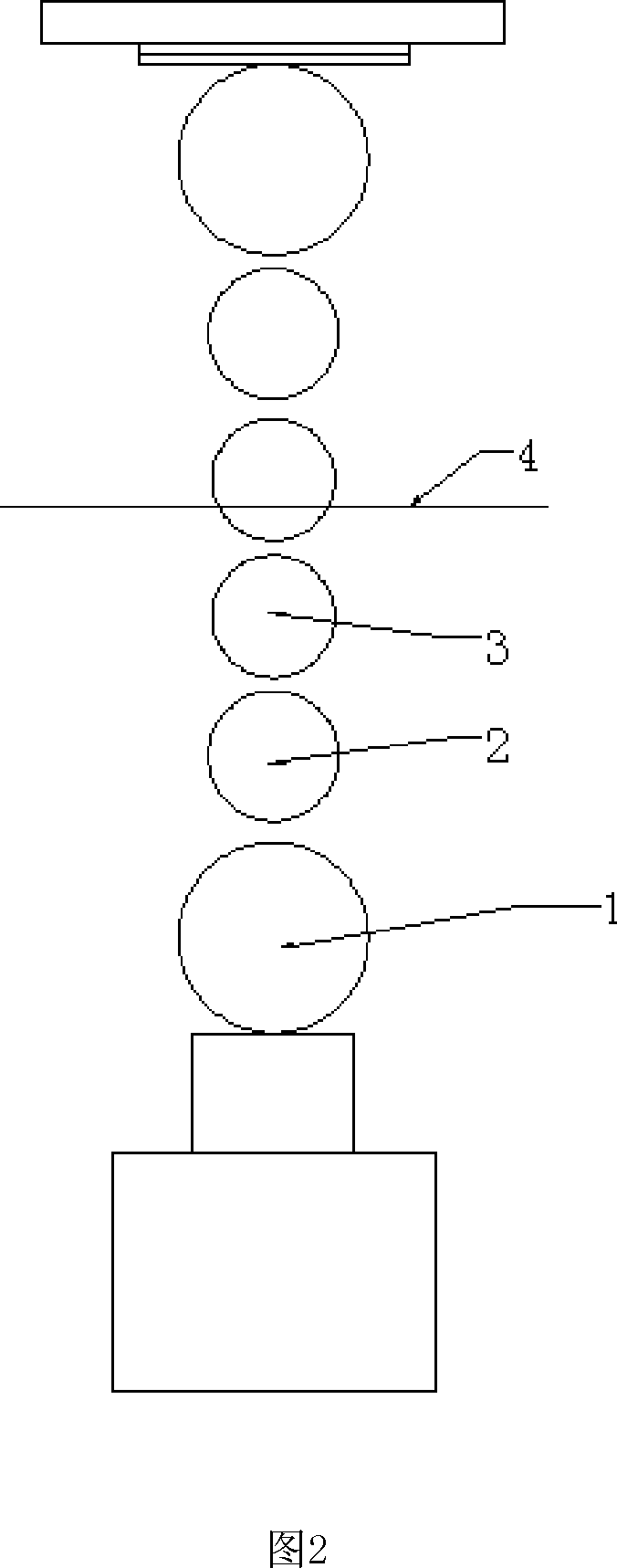

[0026] Embodiment 1: When changing rolls, the control system calculates that the roll gap value δ to be opened is 156 mm according to the roll diameter of the old roll before the roll change, and the roll gap value is δ=δ 0 +δ 1 +δ 2 +δ 3 , when the diameter Ф 1 Replace the 415mm large roll with a roll diameter of Ф 2 For a small roll of 395mm, the roll diameter deviation is Ф Δ =Ф 1 -Ф 2 =20mm, at this time the roll gap value δ recorded by the control system does not change to 156mm, but the actual roll gap δ′ increases to δ+Ф due to the reduction of the roll diameter after the roll change Δ =156mm+20mm=176mm, if the roll deviation compensation is not performed at this time, when the roll gap is closed to zero, there is still a 10mm gap between the upper and lower rolls, so the roll diameter deviation compensation must be performed, and the compensated roll gap value is δ '=δ+Ф Δ =(δ 0 +δ 1 +δ 2 +δ 3 )+(Ф 1 -Ф 2 ), after the roll change is completed, modify the ...

Embodiment 2

[0027] Example 2: If the roll gap value δ is opened to 156mm, when the diameter Ф 1 Replace the 400mm small roll with a roll diameter of Ф 2 When the 415mm roll is changed to a larger roll, the roll diameter deviation is Ф Δ =Ф 1 -Ф 2 =15mm, the roll gap value δ recorded by the control system after the roll change is not changed to 156mm, but the actual roll gap value δ′ decreases to δ+Ф due to the increase of the roll diameter after the roll change Δ =156mm-15mm=141mm, if the roll deviation compensation is not performed at this time, when the roll gap is closed to 15mm, the upper and lower rolls have moved closer together, so the roll diameter deviation compensation must be performed, and the compensated roll gap value is δ′=δ +Ф Δ =(δ 0 +δ 1 +δ 2 +δ 3 )+(Ф 1 -Ф 2 ), after the roll change is completed, modify the roll gap value recorded in the control system according to the roll diameter deviation value of the new / old roll, and the roll gap value recorded in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com